When researchers first realised sulphur deposition levels were falling and yield was being put at risk, the call went out for a new product to resolve the issue. CPM tells the story of DoubleTop.

The difference in yield was astonishing.

By Tom Allen-Stevens

The story of sulphur use in arable crops may be one of agriculture’s biggest successes. Few growers today would consider top dressing their oilseed rape without including sulphur in some form at some point. But just 30 years ago, this was assumed to come from the sky.

The first authority to raise the issue of sulphur deficiency as a potential concern for growers across the UK was Rothamsted Research. “We published our first paper on the subject in 1987,” recalls Rothamsted’s Prof Steve McGrath.

When Steve McGrath published his first paper, it came as a surprise that levels of sulphur deposition across the UK had dropped so low.

“At the time, everyone was concerned about acid rain, so it came as a bit of a surprise that levels of emissions may have dropped to the point at which some soils were actually deficient in sulphur.”

But it had already been noted in Scotland, where the cleaner air meant there was less atmospheric sulphur dioxide. Papers published by Norman Scott of the James Hutton Institute at Aberdeen in the Journal of the Science of Food and Agriculture at the beginning of the 1980s highlighted the lack of sulphur deposition in some lighter soils.

Research based

“Norman was very enthusiastic about the need for Scottish growers to apply sulphur, but no one believed that would be the case further south. Rothamsted, however, was in the unique position to show that it could.”

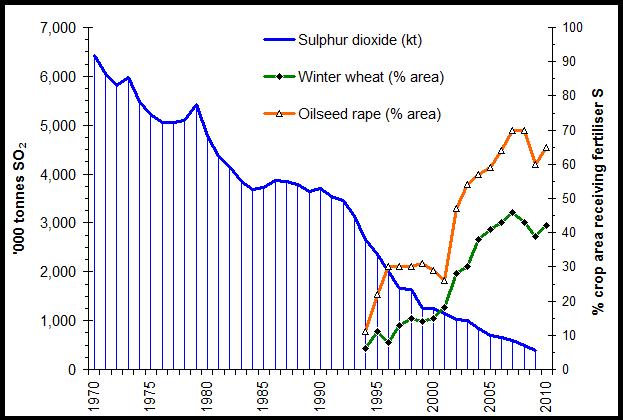

The institute was part of the Acid Precipitation Monitoring Network, keeping tabs on air quality. “We had figures to show that sulphur dioxide emissions had peaked in 1970 and had fallen dramatically since. We decided to undertake some work, particularly on the lighter soils at Rothamsted’s site in Woburn as well as at Harpenden.”

Sulphur deposition and use of sulphur fertiliser.

AHDB-funded trials were set up to investigate the response in OSR, which was known to have a high sulphur requirement. “The difference in yield was astonishing – on these lighter soils, the OSR yield without sulphur applied was half of that where it was applied. That really woke us up,” he notes.

It woke the industry up, too. The work was well publicised, pushed out to farmers through technical journals, countless conferences and farmers’ meetings at which Steve McGrath and colleagues highlighted the work they’d done and the evidence to show OSR needed sulphur.

“We then turned our attention to wheat,” he continues. “The first trials in the late-1990s showed the light Woburn soils yielded just 2.5t/ha without sulphur, but 5t/ha with the nutrient applied. We rolled out trials across the UK, and during 2000-05, found an average yield benefit in responsive sites of 27%.”

By the early 2000s, the research journey had moved on again. “We started to look at bread-making quality. We knew that sulphur was needed in flour to create the right consistency in dough to produce a good loaf volume. So we used wheat from field trials for test bakes, and sure enough this showed a large increase in loaf volume where S had been applied.”

Out in the field, the awareness was beginning to grow, according to CF Fertilisers’ Mark Garrett, who was an agronomist at the time. “Deficiencies were noticed, but misdiagnosed as N deficiency at first, so growers were putting more N on, which was counter-productive,” he recalls.

The key difference is that N deficiency affects older leaves, yet the symptoms were showing up in new leaves – tell-tale S deficiency, he notes. But there was also growing evidence of sub-clinical deficiency, where there’d be a considerable yield response from applying sulphur, even if it didn’t show in the crop.

“Some growers were sceptical and accused us of inventing a problem that didn’t really exist. But the difference here was the level of authoritative research that showed there was an issue that needed to be addressed.”

As awareness was growing, so too was demand for a product that could be easily applied that would get sulphate into the crop. “At the time the right product didn’t really exist,” notes Steve McGrath.

“In Scotland, Norman Scott recommended using micronized S in liquid form through a sprayer, but you couldn’t really get enough on. The difficulty with elemental S is that it has to be oxidised before it can be taken up, and that’s an unpredictable process.

“Sulphate compounds were available, such as with magnesium or potassium, which were appropriate if you needed those nutrients. Ammonium sulphate (AS) was a relatively cheap option, but not balanced – it puts on too high a proportion of S, and it also acidifies the soil. What was needed was ammonium nitrate (AN) blended in the correct ratio with AS.”

This was the challenge facing the fertiliser industry, and in particular CF Fertilisers’ plant at Ince, near Chester. The plant manufactures 1M tonnes of fertiliser every year. Approximately half of this is straight AN, the rest are complex, compound fertilisers, also called true granular compounds, where AN is granulated with differing amounts of phosphate, potash and sulphur.

Lead engineer Phil Hayward was in his late 20s when the meeting was called to decide how a new line was going to be introduced. “One thing the plant has always shown itself to be is extremely flexible. But we play tunes on that – we can make a range of grades, so when there’s a new suggestion you can’t say no. An AN/AS compound, however, had never been done before.”

A true granular fertiliser contains the correct balance of nutrients in every granule, as opposed to a fertiliser blend where there’s a mixture of granules of different types, he explains. “It’s like baking a cake, rather than mixing a muesli.”

It means the products are mixed in liquid form, partially crystallised and then broken up with a blunger into granules. “We’re aiming to make a crumble-type texture that’s lump-free and dust-free. Fines and oversized particles are recycled until the product comes out at the right consistency. It’s a balance, but you get to know the product and the raw materials so well, you can predict a problem before it’s even occurred.

Fine materials

“So there’s a set of rules with NPK fertilisers, but we found these simply didn’t follow when we started bringing AN and AS together. The existing plant produced a lot of fine materials, so we had to develop new equipment to make it work.”

Eventually the team cracked it, and DoubleTop was born – a true compound granule containing 27%N and 30% SO3. Testing confirmed the new granule spread robustly to 24m and accurately to the wider widths growers spread to today. It was consistent, dust and lump-free, the correct proportions of N and S for most crops and easy to use.

Launched over twenty years ago, it fell on a hungry market, recalls CF Fertilisers agronomist Allison Grundy. “In the early years, it was really hard for some growers to get hold of DoubleTop. The biggest challenge for CF Fertilisers was knowing how the demand was going to grow, and then keeping pace with it.”

Ideally, she recommends applying a crop’s requirement of S as DoubleTop with the first dressing in the spring, although it can be used as first and second applications where split dressings are required. “Years of trials have refined our understanding of how much to apply and when. It should be in its readily available, sulphate form in the soil, and the crop will take it up as it uses its requirement of N.

“If applying manures, this does contain S, but some of it will be unavailable and some is lost. AHDB-funded trials have shown a response in OSR to applied S of around 45kg/ha SO3 where manure has been applied. But recent work indicates there’s no benefit in raising rates of applied S for higher-yielding crops.”

In milling wheat, sulphur has an essential role to play in building the correct protein in the grain, but an early season dose should still be sufficient to supply this, she says. “Malting barley also needs S, but conversely uses it early on with the N to build yield, ensuring low levels of nitrogen in the grain.”

The British Survey of Fertiliser Practice has shown a steady increase in the proportion of arable land that receives a dressing of sulphur, notes CF Fertilisers’ David Beck. “On average, about 59kg/ha SO3 is applied to 52% of arable land. 62% of winter wheat and 73% of OSR crops received a sulphur product last year, and it looks like those who are using it apply it at about the right rate.”

Of the CF Fertilisers range, DoubleTop is the biggest-selling compound of the products manufactured at Ince. “We’re seeing an increase in demand for compounds containing S against a decline in NPK use overall,” he notes.

“We find DoubleTop users are also very loyal – various urea/sulphur blends are available, but feedback suggests growers don’t get on well with them.”

For Steve McGrath, it’s a success story. “With more than 50% of cereals and 70% of OSR receiving S applications, I’d say that’s pretty much most growers who need to apply it are doing so. It’s something I’m proud of that we did the research and we got the message out to growers – applied sulphur now makes a significant contribution to crop yields and to quality that may never have happened otherwise.”

What does sulphur do?

Synthesis

Sulphur is used in plants to form amino acids, proteins, and oils. It’s necessary for chlorophyll formation, helps develop and activate certain enzymes and vitamins, and is a structural component of two of the 21 amino acids that form protein.

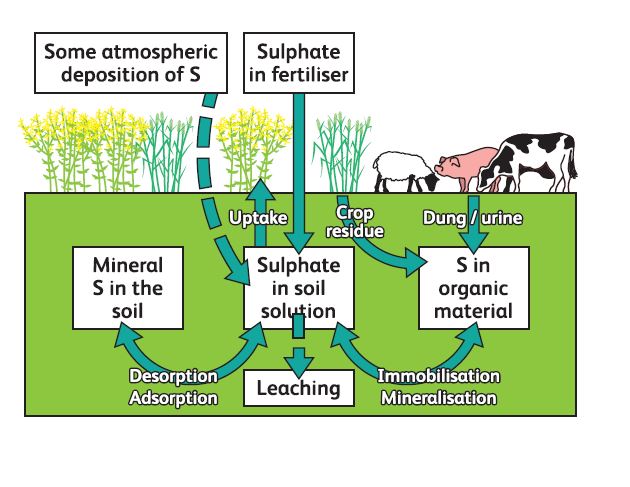

The crop’s need for S is closely associated with N, which is also a component of protein and involved in chlorophyll formation. So a plant takes up a certain quantity of S as it uses N. Unlike N, however, S is not moved within a plant, so it requires a steady source from the soil through the growing season.

Symptoms

The youngest leaves of S-deficient cereals and OSR are often yellow. Later, severely S-deficient OSR crops will have pale flowers. Sandy and coarse silty or loamy soils are most prone to deficiencies, especially in high rainfall areas.

Source

Sulphur is taken up by plants in its sulphate (SO4) form from the soil. Sulphur in the soil, as well as in applied manures or elemental sulphur, must be processed by soil microbes before it becomes available to the plant.

Supply

CF Fertilisers-recommended application rates are:

- Wheat and barley – 52.5kg/ha SO3 in late Feb

- OSR – 112kg/ha SO3 in late Feb

Most fertilisers and organic material are expressed as either SO3 or S. 2.5kg of SO3 contains 1kg of S.

Ease of use and spreadability make DoubleTop a trusted input

Suffolk grower and contractor John Taylor has used DoubleTop for nearly 15 years and it’s now the foundation of his fertiliser strategy for over 1280ha of cereal and oilseed rape crops.

“It’s the first application we put on and provides our crops with all their sulphur requirement for the year plus it’s quality and consistency means we know they’re getting the best start possible from a nitrogen point of view.”

He reckons it’s the best fertiliser product he’s ever used at 32m. “Even in the sometimes difficult spreading conditions at the end of Feb when we often put it on, we know we’ll always get an even distribution of material.”

A long-time advocate of applying sulphur, John Taylor, of F. G. Taylor and Son, Grove Farm, Clompton, near Woodbridge, changed his approach to application following BASIS and FACTS training in 2001.

“I realised to be more efficient from an agronomic point of view, we were going to have to move up to a 32m sprayer and that the liquid fertilisers we were using just weren’t suitable for this.

“We tried using ammonium sulphate but we struggled to spread this to 24m, let alone the wider width we needed. We then discovered DoubleTop and haven’t looked back since.”

Today all 900ha of feed and milling wheat plus the 80ha of winter barley get a 150kg/ha application of the product as soon as practically possible in the New Year. This delivers 41kgN/ha and 45kg/ha SO3 which equates to 18kgS/ha.

“Feed wheat gets a total of 210kgN/ha from solid fertiliser, including Nitram as well as the DoubleTop, while with the milling wheat we aim for a total of 250kgN/ha from solids plus a further 30kgN/ha from a foliar application.

“All the 300ha of oilseed rape get 300kg/ha of DoubleTop which gives 81kgN/ha as part of 200kgN/ha total.”

Having tried nearly all types of fertiliser over the years, John Taylor says it’s DoubleTop’s superior spreading performance and year-on-year dependability that has led to its long term role in his crop nutrition strategy.

“We’ve used coated ureas, nitrogen-inhibited product, straight urea and CAN 27% as well as ammonium sulphate, but nothing is as easy to handle and use as DoubleTop.

“It just seems denser with larger granules and we can use it with confidence in conditions we wouldn’t dream of using urea, for example, and you know it will always spread well.

The fact that it’s a compound rather than a blend is important, too, he says. “You know it’s not going to separate out and that every granule has the correct balance of nitrogen and sulphur locked in it.”

Innovation Insight

CPM would like to thank CF Fertilisers for kindly sponsoring this article, and for providing privileged access to staff and material used to help put the article together.