New technology can deliver marked improvements in how fertiliser is delivered in shortwork and on headlands. CPM gives an overview of Amazone’s Argus Twin.

By Tom Allen-Stevens

As harvest approaches, growers have been advised to assess their crops and in particular look critically at how accurately fertiliser has been spread.

“This is the time of year when overlap in the tramlines and inaccuracies on headlands become evident,” points out Simon Brown of Amazone.

“There’s often the assumption that liquid is the way to go to make improvements, but new technology in solid fertiliser application such as Amazone’s Argus Twin on-line spread pattern monitoring system delivers far superior accuracy – rolled out onto farm this spring, we’ve had some good feedback

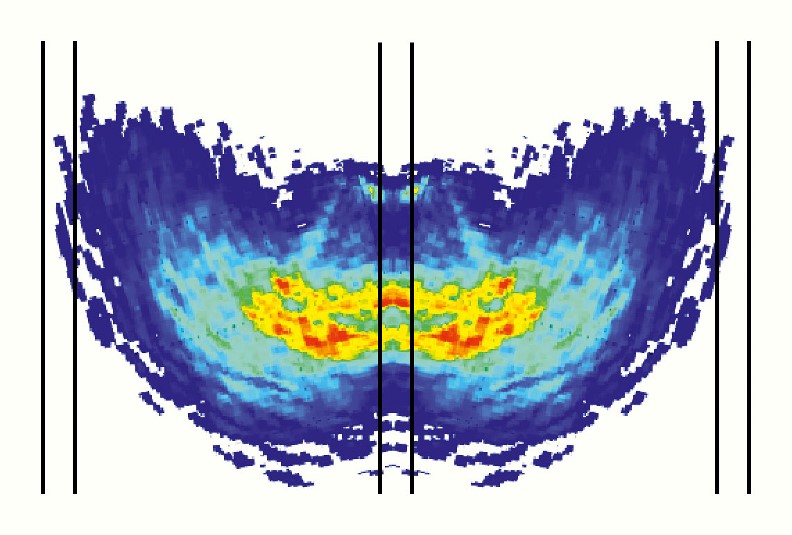

3-D effect logs a birds-eye view of the fertiliser leaving the disc at its most accurate position.

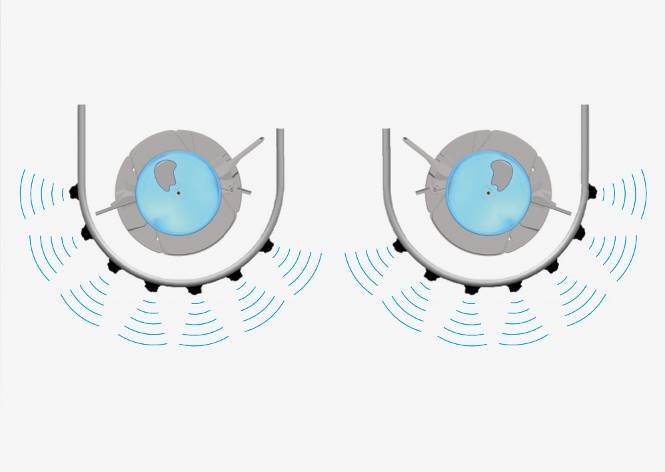

The system monitors the spread fan and automatically regulates the lateral distribution, which is based on radar technology.

It features seven radar sensors mounted above each disc so that it constantly monitors each individual spread pattern from both the right and left-hand sides of the spreader, effectively monitoring the pattern in a 3-D view.

If the spread fan is wrong then the system can readjust the electric delivery system independently to each other if necessary.

“The system functions by entering into the ISOBUS terminal the predetermined ‘throw-off angle’ which is specific to that fertiliser,” explains Simon Brown.

Seven radar sensors mounted above each disc constantly monitor each individual spread pattern from both the right and left-hand sides of the spreader.

“On the basis of this value, Argus Twin constantly checks whether the predetermined direction of throw for the fertiliser is in fact being maintained by the spreading disc.

“When the actual spreading angle deviates from the desired spread pattern due to inconsistencies within the fertiliser, worn spreading discs, travelling on slopes or the starting and stopping procedures, the ZA-TS spreader readjusts, on its own, the delivery system – and that of each side individually.”

Electric delivery system

The precondition for use is the electric delivery system. Argus Twin can be utilised on both mechanically-driven ZA-TS Tronic spreaders or with a ZA-TS or ZG-TS Profis Hydro spreader with hydraulic spreading disc drive.

“For the TS spreaders, the Argus Twin system always guarantees, due to the constant on-line monitoring and the subsequent re-adjustment of the delivery system if necessary, the optimum lateral distribution of the fertiliser,” continues Simon Brown.

“This ensures the most effective use of fertiliser and is the basis for optimised crop management.”

The system gets going immediately and operates even when border spreading and when part-width sections are switched off and on.

In hilly terrain, Argus provides a slope compensation of the spread pattern via the automatic readjustment of the delivery position of the fertiliser.

Exeter-based contractors Stuart Partners have put the Argus system to the test.

One user who’s put it to good use is Troy Stuart of Exeter-based contractors Stuart Partners.

3-D View

Argus has been developed through the 3-D view of fertiliser distribution that’s assessed at the Amazone Test Hall at the Gaste factory.

Here the fertiliser spreader revolves on an axis above around 80 half-metre square collection trays, each with a weigh cell which monitors many times a second the amount of fertiliser entering it.

These thousands of weighings can then be computed into a 3-D effect, allowing a birds-eye view of the fertiliser leaving the disc at its most accurate position.

“We can use this information to optimise the on/off points of the spreader when passing over the headland tramline in odd-shaped fields where there is plenty of short work and where the GPS-Switch headland shut-off system now looks after 128 part-width ‘boom sections’ on the headland,” continues Simon Brown.

This improved accuracy on the headland prevents lodging and maximises yield, he says, cutting the overall fertiliser bill by around 5% and that’s without taking into account the husbandry advantages.

“The second big advantage of the 3-D view is that we can film the fertiliser leaving the disc continually. Then if for some reason the spread pattern changes, then the spreader knows this and can corrects things for you – that the basis for Argus.”

Web-based information

There’s more information on Argus Twin on the Amazone website.

Also available is Amazone’s E-Learning programme, that offers interactive driver training for owners and operators to teach themselves how to calibrate spreaders and operate features such as auto shut-off.

There’s also an Output Calculator [http://www.amazone.net/1513.asp], while the FertiliserService App, available on iPhone and Android platforms, gives operators on-the-go access to settings charts.