Avadex has been a valued tool in the fight against grassweeds for over 50 years, and helped pioneer the pre-emergence herbicide programme, but almost disappeared. CPM tracks its story and rebirth.

Avadex BW was a brilliant product, but 10-15 years ahead of its time.

By Tom Allen-Stevens

Anyone who has ever worked on an arable farm in the autumn, especially in the South, East and East Midlands will probably have come across Avadex (triallate). It’s believed to be the single most successful herbicide product, apart from Roundup (glyphosate), with a history that spans over five decades.

But anyone who has ever worked with Avadex has probably also asked the question “why isn’t it available as a liquid?”

The 15kg/ha microgranules were introduced in 1994.

“Avadex was first introduced as a liquid formulation, but it was volatile, so had to be incorporated into the top 25mm soon after spraying,” explains Wyn Evans, who was working for Boots the chemist on farm sales when Avadex BW was launched.

Avadex was discovered and brought to market by Monsanto, introduced in the US and Canada in 1960. Available both as diallate and triallate, it was the latter, branded Avadex BW (barley and wheat) that was introduced in the UK in 1964. It was sold as a core pre-emergence product to control grassweeds and broadleaf weeds, and it was its prowess on wild oats that caught the attention of growers.

“Avadex BW was a brilliant product, but 10-15 years ahead of its time,” continues Wyn Evans. It was marketed through Boots and Chafer and he was responsible for relaying technical trials work to farmers.

Accurate Incorporation

“The trouble was, the equipment to accurately incorporate it, or to drill the crop to the right depth, didn’t exist in those days. A lot of growers were spinning on their wheat or drilling it to just 10mm depth. With today’s equipment it would be a piece of cake to get both application and drilling right.”

The granules were launched in 1969 and had to be precision applied through a specialist applicator at a rate of 22.5kg/ha. The 15kg/ha microgranules (Avadex Excel 15G) weren’t introduced until 1994.

An applicator was developed by Horstine Farmery – the 16ft (4.9m) TMA2. “We started off with just the one TMA2 that I used to travel around with in the back of my Ford Cortina. But it took off within months and soon we had a fleet of machines on trailers that were dispatched around the UK for farmers to use,” recalls Wyn Evans.

“Avadex did a super job on wild oats – get it right and you could get 99% control. The TMA2 was the only piece of kit that would apply a granule at that rate evenly and precisely. But it was way before GPS, so missed strips were commonplace. That was a great sales tool for me, however, because it illustrated the effectiveness of the product.”

Roy Lawrence worked for Monsanto for around 25 years and was commercial development manager for Avadex after joining the company in 1980. “It was the reliability it brought to weed-control programmes that farmers really liked,” he recalls.

“Avadex was always sold as a partner product in the pre-em slot, part of a programme that would include other pre-em herbicides. It delivered grassweed control, but also had an effect on broadleaf weeds, which stood it apart from other actives at the time – it was a case of 2+2=5.”

Throughout the 1970s and 80s, Avadex enjoyed growing popularity with farmers, one of a number of core products well supported by Monsanto. Growers of continuous cereals especially relied on it to keep grassweeds, particularly wild oats, to a manageable level.

It was also sold as Wallop, a mixture with Tribunil (methabenthiazuron), a product of joint research from Bayer and Monsanto, with a stronger weed portfolio. There was even a 30sec TV commercial to expound its benefits.

But it was the rise of resistant blackgrass that saw its use take off. “Between 1993-96, sales more than doubled and peaked at around 300,000ha,” reports Roy Lawrence. “Growers were struggling with blackgrass resistance, and this has always been one of its great strengths.”

Resistance to post-emergence fop and dim chemistry was rising, while triallate sat in a completely separate herbicide group from all other chemistry used on the weed, with a different mode of action.

Dr Stephen Moss confirms its credentials. “Avadex does provide useful control of blackgrass, particularly in dry conditions. It is affected by resistance, but no more than many other pre-em herbicides, so I don’t see this as a particular issue. It has always played a useful role in programmes, and continues to do so – its efficacy on bromes and wild oats adds to its value.”

Despite this, its fortunes were short-lived. “Avadex went from feast to famine, one year to the next, dependent on the weather,” notes Roy Lawrence. “In 2000, the very wet autumn saw use halve. It never really recovered, because the next year saw the introduction of flufenacet in Crystal (includes pendimethalin).”

Then in 2003, Monsanto was faced with the prospect of having to invest millions of dollars improving the production facilities, now almost 40 years old, as well as in re-registering the active ingredient. The company’s core focus for investment at that time was on seed and herbicide-tolerant crops and the global rights to triallate chemistry were sold the following year to Gowan.

For the next few years, the use of flufenacet and new post-em chemistry in the form of Atlantis (mesosulfuron+ iodosulfuron) kept a lid on sales. But again, it was the rise of blackgrass resistance that brought another change in fortunes for Avadex.

Dr Dominic Lamb was involved with Avadex when he worked at Monsanto. “I joined Gowan in 2011, just as Avadex was having a rebirth and set about developing the market for it. I spent as much time in 2011 and 2012 talking to machinery companies as I did to agronomists.”

Chafer Machinery had bought Horstine in 2002, including the Avadex applicator, but sales of the TMA4 12m version were practically non-existent, notes Chafer’s Joe Allen.

“It remains a very good machine, however – there’s still one of the original models that comes into the yard for STS testing every year and works perfectly.”

Individual metering

He attributes the accuracy down to the individual metering system. “There are 12 rotors for each of the 12 outlets. Positive displacement parts off the perfect amount of product in each segment of the rotor.”

With the rebirth of Avadex, Chafer was under increasing pressure to relaunch the TMA4. “We relaunched it in 2014, and it’s now available either on a three-point linkage or trailed, for use with an ATV, for example – we sell around 20 units every year. Two years ago, we reintroduced the Cascade for bigger contractors that reaches up to 24m. We also retrofit and make bespoke kit up to 36m,” he says.

The level of control can be directly proportional to evenness of application, adds Gowan UK and Ireland technical manager Rob Plaice. “If it’s too windy to spray, it’ll be too windy to apply Avadex. Also, any damaged deflector plates or poorly maintained pipework can cause striping.”

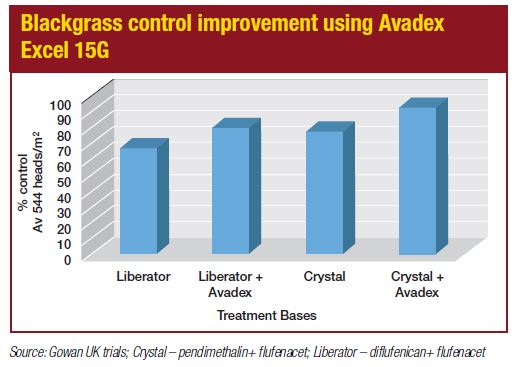

Trials show Avadex adds anything from 4-60% control of blackgrass. “Generally, growers can expect a 15-20% lift on a standard autumn herbicide programme.”

He advises growers to drill, roll, and then apply Avadex, either before or after the pre-em herbicide. “The important thing is to apply it before the blackgrass emerges. But as with all chemical control, Avadex works best where you’ve used cultural control methods to get blackgrass populations down to a manageable level.”

Pioneer of the pre-emergence programme

When Roger Allen took over as manager on a 200ha Hants arable farm in 1967, the wild oats were so bad, land had to be fallowed to keep them in check.

“The farm was completely infested. It was cropped with continuous spring-sown cereals. The product on the market at the time was Carbyne (barbane), which had a very tight usage window.

“I’d heard about Avadex BW, and we tried a strip to see how it worked. We had to produce the seedbed, drill, spray and then incorporate the chemical.”

Drag harrows were used, making sure the points didn’t go too deep to get surface stirring. Two passes were made, travelling at a forward speed of just 6-8km/h. “It was labour intensive, but very effective – control was somewhere around 90%.”

The next year, this moved to a whole farm treatment, and with the ability to get wild oats under control, Roger Allen began to introduce winter cereals across the farm – a rarity in that part of the world at the time.

“It was Avadex that really taught me, and other farmers, the value of the pre-em herbicide, and how to make best use of it. Post-em chemistry was available, but pre-ems became the valuable tool that kept weed competition down and allowed the crop to get established – you realised just how much yield you lost otherwise,” he notes.

“The Avadex granules came in and these were used with huge success, but in my view never worked as well as Avadex BW applied and incorporated correctly.”

Over the years he’s seen blackgrass take over as the main problem weed, but believes the fundamentals of control remain the same. “Good early control has always been the key to success with weeds. But I don’t see that we’ll get any new mode of action. The secret to getting more out of the chemistry we have is to develop better formulations and use it more effectively.”

Formulation remains the technical challenge

Triallate is a thiocarbamate and sits in the Herbicide Resistance Action Committee (HRAC) Group N, differing from diallate by just one chlorine atom. It’s a fatty acid inhibitor, which alone may not be enough to kill a plant, but severely damages the waxy cuticle, making it very vulnerable to other herbicides, or even environmental stress.

“Thiocarbamates interfere with lipid synthesis at the very early stages of plant development,” explains Gowan head of chemistry Jim Essinger, who previously worked with Monsanto. “But unlike ACCase inhibitors, it acts at more than one point, which reduces the threat of resistance to triallate chemistry.”

The technical challenge with Avadex has always been its formulation, he continues. “The active ingredient adheres well to soil particles, particularly clay and loam soils. There it creates a chemical layer that affects weeds that germinate in that layer, but not the crop that emerges from below.

“But volatility increases with soil moisture. That’s why the early formulation of Avadex BW had to be incorporated. With the granules, a special clay compound is used onto which the ai is absorbed. We can control the nature of this compound and it acts as a reservoir for the ai, rather than relying on soil particles.”

The struggle to find a new liquid formulation stretches back over 30 years. “We needed a water-based formulation that did a better job of controlling the availability of the ai, but that also matched the current formulation in terms of weed control, cost and regulatory acceptability,” he says.

Progress really started to be made when the development team started using capsule suspension (CS) formulations. This encapsulates a tiny amount of ai in a polymer capsule just 4-5µm in diameter.

“While immersed in water, the polymer is stable, but when sprayed on the field, it breaks down and releases the triallate.”

This raises another technical challenge, however. “In what would be considered good pre-em soil conditions, the new CS formulation, Avadex Factor, works very well. But in very wet or very dry conditions the higher dose of triallate provided by the granular Avadex Excel 15G can provide a more robust solution to the grassweed problem. When it’s very dry it’s not ideal for any product and also unlikely that the grassweeds will be germinating,” he explains.

While iterations in formulation continue, getting it through registration for use in the UK has been a struggle, reveals Rob Plaice. “We finally got approval last autumn, but too late for use, so this will be its first commercial year.”

The product will have a good range of tankmix options and should provide ease of use for those looking to add Avadex to the autumn herbicide stack. However, for now, Rob Plaice advises growers to stay with granules if they can.

“The full, authorised rate of liquid delivers 1620g/ha of ai, which is 72% of the rate delivered by the granules. So those wanting the full effect of Avadex on high populations of grassweeds should continue with granules.”

Innovation Insight

CPM would like to thank Gowan for kindly sponsoring this article, and for providing privileged access to staff and material used to help put the article together.