Growers struggling against blackgrass need a powerful plan. In the first of five articles that explore a new approach, CPM studies the role of cultivations.

You have to take the financial hit for the long-term benefit.

By Tom Allen-Stevens

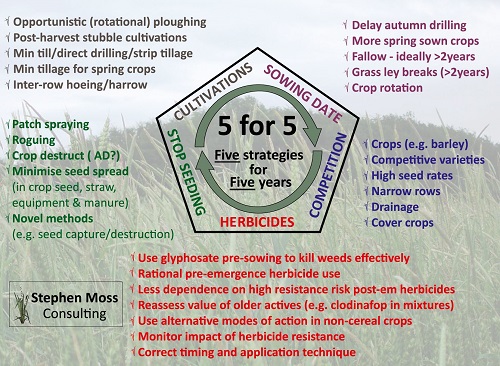

Adopt five strategies for at least five years against your blackgrass, only one of which is herbicides. That’s the way to substantially reduce the grassweed providing new seed production is minimised, according to blackgrass expert Dr Stephen Moss.

Exploit the one weakness blackgrass has, says Stephen Moss – a relatively short seed persistence – and you can reduce your blackgrass population by over 99%.

A new initiative, ‘5 for 5 to beat blackgrass’, has received industry-wide support and brings in line all best practice and research on blackgrass to help growers take an approach that’s most likely to bring the grassweed under control.

So why five years? “This exploits the one weakness blackgrass has,” explains Stephen Moss. “Bury the seed and 74% of it will die within a year – that’s a relatively short seed persistence. If you can prevent seed return for a full five years, you can potentially reduce your blackgrass population by over 99%.”

So what’s new? “There are no new methods of control. This is about using the existing weapons we have more effectively.” These have been grouped into five key areas (see panel below). Growers should plan a strategy for each field, involving all five of the main components, and then monitor progress, he advises.

“Record the blackgrass – how much you have and its location within a field – then review progress annually. Revise the plan if necessary, but there are no quick fixes here.”

And he’s been encouraged by the responsible approach growers are now taking. “I recently visited one farm in continuous cereals that’s battled blackgrass for decades. There’s a field that’s been in spring wheat for three years and it’s essentially clean, but the grower’s resolved to put it back into a spring crop for at least another year.

“You have to take the financial hit for the long-term benefit. With Brexit, times are set to get tougher, so use the next five years to get your house in order,” he urges.

And CPM is falling squarely behind this approach. This is the first in a series of five articles that explores the individual strands of this 5 for 5 strategy. Over the next few months, this’ll bring the very best advice from all the UK’s leading authorities on blackgrass and put it on the page in front of you.

Cultivations is where we start. “Here it can be difficult to avoid total confusion, and often the advice conflicts,” notes Stephen Moss. “Do you go min till or deep plough? The main thing is to have some form of strategy.”

There are some basic principles to bear in mind. Blackgrass seedlings can only emerge successfully from about the top 5 cm of soil. They need to have lost dormancy and require moisture so seeds pressed into the surface or in the top 5cm of soil are likely to germinate, provided conditions are moist. But bury them deeper and many will go dormant or germinate and die. Knowing what you have in the seedbank – its age and depth – is crucial for a successful plan.

“Keeping cultivations shallow is fine – that puts the blackgrass where you can see it. Experience suggests pre-emergence herbicides work best on shallow-rooted blackgrass. The main aim, though, is to get as much of it to germinate as possible outside the crop and to destroy with cultivations or spray it off with glyphosate. But if you have lots of blackgrass, you may find no amount of flushes will bring the population down to one you can control.”

So there’s the option of what he calls ‘opportunistic’ ploughing, or doing so when it’s most effective. “There are two things to bear in mind if you plough. Firstly, it’s only effective if you bury more seed than you bring up. And you must achieve good inversion – ploughing match standard. Control through ploughing averages 69%, but this varies from 96% improvement to making matters worse by 82%.”

One of the quandaries with cultivations is whether to incorporate the straw residue. “Any soil disturbance will tend to cover the blackgrass but it won’t germinate if it’s too dry. A primary aim must be to incorporate straw effectively to get the best possible seedbed for pre-ems to work to their best effect. Too much straw on the surface will reduce herbicide efficacy. What’s more, a mat of decomposing straw may keep seeds dormant and delay germination.”

Work carried out at Syngenta’s Innovation Centre in Cambs appears to back this up. In trials last year, the efficacy of pre and post-em herbicides were trialled with three different cultivation strategies – ploughing, min-till and direct drilling.

“In the direct drilling plot, we looked at the effect of straw removal,” notes James Southgate of Syngenta. “On the one side, all the straw was removed, while the other received extra chopped straw, so barely any soil was visible.”

The extra straw suppressed blackgrass emergence in the untreated plot by 10%. “This may be counter-productive if you’re looking to flush weed seeds,” he points out.

While 94% control from pre and post-em chemistry was achieved in the direct-drilled plots with residues removed, this dropped by 20% where there was plenty of straw. The reduction in efficacy of the pre-em alone was 12%, reports James Southgate.

“It’s worth considering what you’re doing with straw and residues as it can have a significant impact both on emergence pre-drilling and on herbicide efficacy,” he says.

Sarah Cook of ADAS believes it’s best to leave the stubble untouched to encourage blackgrass to germinate. “Mixing the seed into the soil simply makes it more dormant. Leave it on the surface and it’ll germinate, provided there’s moisture and it wants to.”

And that’s another of the problems with cultivations and blackgrass. There’s a second type of dormancy brought on by conditions during seed ripening – if it’s hot and dry, seed will be more inclined to germinate soon after it’s shed. Cold and damp, and there’s a more protracted dormancy.

“It’s been a funny year,” says Sarah Cook. “Blackgrass flowered and shed early. So it ripened during a colder period early in the spring, and germination is around 27% as a result – that’s average to high dormancy, making stale seedbeds more of a challenge.”

There’s no one solution for cultivations that fits every farm, notes Stephen Moss. “This is a complex area, driven very much by individual soil type, prevailing conditions and preference. What’s important is that the crop is given the best start and the pre-ems the optimum seedbed to work. But the key point is to have a plan for your cultivation policy which takes the effects on blackgrass into account. On-farm trials may be the surest way to work within these parameters towards a system that brings best results.”

Keep agronomy in mind while it’s out of crop

Giving the out-of-crop part of the year as much care and attention in its arable management as the in-crop part is essential for growers tackling resistant blackgrass, stresses Barrie Hunt of Monsanto.

“It’s not an agronomic breather, but a fundamental component of the whole weed-management cycle,” he says. “Growers should aim for two good pre-planting glyphosate treatments in most seasons in the 4-6 week gap between harvesting and drilling.”

He sees combining as the first cultivation and notes that well chopped straw, evenly spread will minimise the trash problems that can get in the way of stale seedbed consolidation. “This will also maximise your soil moisture retention.”

Cultivations within 48 hours of combining can provide the best environment for weed seed germination. Keeping these shallow will limit moisture loss while ensuring the weed seed stays near the surface for rapid germination. “Use a Cambridge roll within a day of cultivation to bring a high level of soil contact and rapid germination of small weed seeds.”

Allow as much blackgrass as possible to germinate and emerge before spraying, he advises. “If that means some of it is at 2-3 leaves then that’s fine.”

As soon as product recommendations suggest, cultivate again (if necessary) and consolidate the ground again to eliminate another flush of weed growth ahead of final seedbed preparation and drilling.

“Use a glyphosate formulation with the shortest possible cultivation interval. It’s especially important to follow these steps where short term cover crops are used, so the first weed flush can be sprayed off before they’re planted and a further flush knocked out with the cover ahead of drilling,” he adds.

Hot and dry conditions, rainfall within a few hours of spraying or hard water conditions can compromise efficacy. “This makes it important to use glyphosate formulations designed for challenging conditions and complementing them with specialist adjuvants or water conditioners wherever necessary in hard water areas.”

He advises medium flat fan nozzles for optimum results on one-leaf grasses and water volumes of 100 l/ha or less under normal conditions. “Under dry conditions, you should spray early in the morning to optimise weed uptake,” adds Barrie Hunt.

Growers should also use the right rate of glyphosate for the job. Typically, that’s 540g/ha to control grassweed seedlings of up to six tillers and up to 1800g/ha for the most difficult perennials.

Good establishment key in five-year plan for winter oilseed rape

Put oilseed rape on your cleaner land and don’t delay drilling to encourage a flush of blackgrass. These are two of the key points Dick Neale of Hutchinsons stresses for success with OSR in bad blackgrass situations.

“Start by looking at your cropped area and pick out the red, amber and green zones, denoting how successful your control of blackgrass has been,” he advises. “Put the OSR in the green zones.”

Success with the crop is all about getting a good establishment, he says, while blackgrass must be kept shallow so it can be knocked out by propyzamide and/or carbetamide later in the year.

Hutchinsons has now completed its first year cropping a new blackgrass focus site near Banbury, Oxon. Here, lessons learned from its Brampton Centre of Excellence in Cambs are being put into practice to reduce a population that averaged 1635 plants/m² in Sept 2016, with infestations in some areas topping 4000 plants/m².

The silty clay field in OSR presents a particular challenge, notes Dick Neale. “A lot of surface water washes into it from the surrounding area. You can see the soil surface glisten in winter and the result is an impermeable layer the worms don’t like and blackgrass takes advantage of. It highlights the importance of correcting fundamentals, such as drainage.”

In 2016, the spring barley crop was swamped by blackgrass, and sprayed off with glyphosate. “For the following crop, we used a Cousins Microwing and seeder to sow the initial winter OSR crop with minimal soil disturbance. This did a perfect job and created a lovely seedbed, but the level of blackgrass emergence was still phenomenal and we had to spray it off.”

A lack of organic matter residue in the soil surface and a high population of slugs that took the OSR as it emerged compounded problems. The crop was re-drilled with a Väderstad Rapid in late Sept.

“We trialled subsoiling in two strips across the field. The aim was to replicate the broken surface typical of sub-casting OSR crops, with the legs on the Cousins Patriot set to 250mm depth and the discs lifted out of play,” he recalls.

Where the soil had been deep moved, the improvement in establishment was remarkable, notes Dick Neale. “But when we inspected the soil profile, we could see no obvious reason for this with no effect on rooting depth nor root size.

“The improved establishment must have come from the disruption of the soil surface – as the field’s major problem is surface flooding, leaving the surface ‘sub-soiler rough’ has allowed water to infiltrate and provide better conditions for the late drilling to establish.”

But blackgrass control where the soil had been moved to depth was significantly worse than the minimally moved seedbed. “We’ll now focus on stabilising the soil surface for good water infiltration and reliable crop establishment.”

And a good establishment is absolutely fundamental, stresses Dick Neale. “A better crop makes better roots, which put blackgrass on the back foot.” He has a number of key points which help ensure this:

- Don’t delay drilling. OSR is best established in Aug, while most blackgrass will flush during Sept, so effective stale seedbeds are not an option.

- Sow using a minimal disturbance technique. Dick Neale warns against subsoiler seeders as they can encourage blackgrass to germinate from depth. But the Cousins Microwing, Claydon, Mzuri and Sumo DTS strip-till drills do a “fantastic” job for OSR, he says. Any topsoil cultivations should move no more than 75mm.

- Increase seed rate for early competition.

- Use placed fertiliser at sowing. Band sowing, with only planted rows treated, is ideal as this feeds the crop, not the weed.

- Apply a pre-emergence, grassweed-active herbicide such as metazachlor. This is a good starting point and takes the sting out of the blackgrass.

- Apply propyzamide/carbetamide when sufficient moisture is available and blackgrass is small. This may be in early Nov, which could be earlier than your traditional timing.

With a low population of blackgrass present in the OSR at Banbury before the combine went in, the plan is to crop it with spring barley next year. “We won’t be using a cover crop because the focus is to flush out the high population of blackgrass, which we’ll do with cultivations and glyphosate,” states Dick Neale.

“There’s a move to put it into late-sown winter wheat, which has worked well this year. But that’s not a cropping option you want to hang your hat on – it might not work so well this autumn.”

Prepare now for spring barley

The right autumn cultivations will bring the best results in spring cropping, according to trials at Hutchinsons’ blackgrass site at Banbury. Cotswold agronomist Toby Kellie has overseen spring barley establishment trials, which indicate crop competition is the pivotal aspect of success over blackgrass.

“Producing the best environment for spring barley will have the greatest effect on suppressing blackgrass numbers,” he notes.

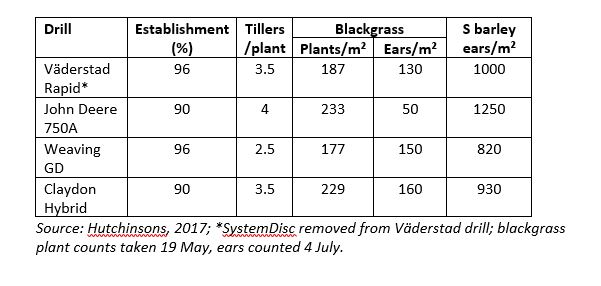

The trials pitched four leading drills against each other, with plots drilled at 500 seeds/m² into the loamy silt/clay soil on 6 April (see table below). “The plot drilled with the John Deere 750A had the most blackgrass plants to start with, but the crop tillered the best and produced the highest spring barley ear count, which in turn led it to having the lowest amount of blackgrass heads,” reports Toby Kellie.

His advice for those planning a spring crop is to start cultivations now. “Leave it for a month after harvest to maximise seed predation and to get a flush. Then cultivate with tines to around 50mm depth – a stubble rake isn’t really enough to activate the blackgrass.

“Spray with glyphosate before the autumn cultivation, again in Jan and then just before drilling. Don’t let the blackgrass get too big, and if you have a lawn, that will inhibit further growth. But don’t move the ground in the spring – that’s essential,” he notes.

“Crop competition is the key form of control with your spring crop, and don’t rely on tillering alone – keep the seed rate up.”

These findings were echoed in seed rate trials, where spring barley was established at 250, 375 and 500 seeds/m². Two rows were then cross-drilled to give rates of 375, 500 and 675 seeds/m².

“There’s a massive decline in seed return through increasing seed rate,” notes Hutchinsons’ Neil Watson. “At higher seed rates, you get more tillers/m² and there’s less variability.”

At the low seed rate, the crop was too open and wouldn’t compete against blackgrass, he says. 375 seeds/m² is where most crops are drilled, but it’s at 500 seeds/m² that he says crops dynamics change and blackgrass gets crowded out.

“The spatial arrangement is better with cross drilling, which is good for the crop, but may not be practical, and could create too much disturbance at drilling. High-population crops will also need a good PGR,” he advises.

But don’t rely on pre-emergence herbicides for the spring barley crop, says Farmacy’s Ed Brooks, taking growers round the herbicide treatment plots. “Control generally was poor due to dry conditions. Avadex (triallate) improved every treatment, although the granule was better than the liquid formulation. Defy (prosulfocarb) knocked the crop, so I’d be careful with its use on spring barley.

“But despite poor results on blackgrass this spring, I’d always advocate a pre-em, such as Liberator (flufenacet+ diflufenican) because it takes out the early competition, especially from broadleaf weeds.”

Spring barley establishment – how the drills compared