Farming in the Cotswolds, Toby Hogsbjerg has been experimenting with a number of different tactics to coax improvements from his limestone brash. CPM visits to discuss his on-farm fungicide trial.

It’s a challenge to get the best out of this limestone brash.

By Tom Allen-Stevens

It probably counts as one of the most breath-taking views the English countryside has to offer. But Toby Hogsbjerg’s focus is on his crop of RGT Illustrious winter wheat, rather than the Cotswold setting that surrounds it. It’s mid Aug and this promising milling variety should be in the barn, but there’s yet another menacing cloud rolling in that suggests the combine may well stay in the shed for another day.

The soil texture within the thin Cotswold brash changes from sandy loam to a heavy clay that loves blackgrass and is more vulnerable than most to a lack of moisture.

“You can invest a lot in this land and not get a lot out,” he says. It’s the effect of this year’s spring drought, rather than the catchy rainfall at harvest, that concerns him. His thin Cotswold brash is more vulnerable than most to the lack of moisture.

“The interesting aspect is that there was very little disease this year, and many would have considered paring back on fungicide. But if it turns dry, the plant needs every bit of green leaf it has to help it survive.”

The estates are characterised by 300ha of woodland and a further 150ha of permanent pasture that sit in steep-sided valleys.

Particular interest

It’s one reason why he’s taking a particular interest in the fungicide programmes applied to this field of Illustrious. As part of the BASF Real Results Circle, Toby’s one of 50 growers taking part in on-farm trials, putting two fungicide regimes side by side and sharing results to find out what really works in the field (see panel below).

“It’s a challenge to get the best out of this limestone brash. We’re 180m above sea level and the soil texture changes from sandy loam to a heavy clay that loves blackgrass – there’s huge variability and none of it hangs on to moisture.”

The land he farms is in two blocks, lying just north of Burford, Oxon. There’s around 400ha of arable land on the Wilcote Estate, with another 600ha at Swinbrook. The estates are characterised by 300ha of woodland and a further 150ha of permanent pasture that sit in steep-sided valleys, with the majority of the arable land rising up over the Cotswold hills. Swinbrook is in Higher-Level Stewardship, while Wilcote is in the process of joining Countryside Stewardship.

RGT Illustrious wheat heads up the rotation – finding a decent spring crop to rotate with it hasn’t been easy.

Brought up on a family farm in Suffolk, Toby himself has spent most of his career on farms in the Eastern Counties with large vegetable and potato enterprises, then moved to Swinbrook in 2008 to become farm manager. “My focus here is to build the soil fertility, and take some of the intensity out of the system. When I arrived, we joined the two estates together and to make it work we used an oilseed rape/ wheat/ wheat/ barley rotation at Wilcote and wheat/ wheat/ OSR/ wheat followed by a spring crop at Swinbrook. But this wasn’t working for the soil,” he notes.

“We’re aiming now for an eight-year rotation, although finding a decent spring break that works on these soils isn’t easy.” While winter wheat, barley and OSR continue to dominate the rotation, linseed, spring beans, spring wheat and most recently soya have come in to open up the cycle and help against blackgrass.

There’s also been something of a return for a livestock enterprise that traditionally shaped the Cotswolds. “We’ve always had sheep grazing the permanent pasture. Now we’re growing more fodder and cover crops and including them as part of the rotation. So if we’ve a field with a high population of blackgrass, rather than growing a winter crop, we’ll fallow it with spring-sown cover crops, or put in forage crops for grazing in front of a spring crop.”

Typically the forage crops, such as stubble turnips, fodder rape and fodder radish, will be planted soon after harvest. “We’ve been grazing on and off for the past three years, but this is the first year we’ve had a formal grazing agreement.” Rather than run its own livestock enterprise, the farm has an arrangement with a local shepherd who stocks the land to fit in with the forage available – there’s 140ha of forage crops across the two estates, with a further 40ha of cover crops at Swinbrook.

“The grazing usually starts with rye, turnip and radish in mid Nov through until Christmas. In these crops, the roots are fairly well developed by late autumn. The sheep move to stubble turnips and forage OSR in Jan and Feb, while there may be some late-sown mustard or other spring-sown cover crop that has potential for late grazing,” explains Toby.

Finding a good break crop to follow has been a struggle, he admits. “We’d really need to drill spring barley in Feb, but blackgrass still comes through in March and April, and the later we can drill in spring the better to give these high, cold soils a chance to warm up.

“Spring beans and linseed are the main crops, although results from linseed have been variable and you rarely make money from beans. Spring wheat is an option if the seed cost is sensible, and we’ve even grown millet, which is good at smothering blackgrass. There’s currently 20ha of soya – sown late, that really suits this land, so we’ll see how it performs.”

But he keeps his options open for what takes the land in spring. “There’s always a plan, but it doesn’t have to be a harvestable crop. One option that’s working well is where we’ve fallowed the land over winter then established a spring-sown cover crop – that’s improved the soil immensely.”

He was prompted into this with a field that came out of wheat in 2015. “It was a carpet of blackgrass, so rather than risk an autumn-sown crop, we left the blackgrass to chit over the winter then sprayed it off and established a mix of cover crop species in early spring designed to improve the tilth and fix nitrogen. We then direct drilled with winter wheat in Oct – the crop looks far better than other wheats.”

Hand-in-hand with cropping changes has been a focus on reducing compaction. “When I came here, the machinery was all wheeled tractors and standard tyres on equipment. We’ve changed this and implemented a new machinery policy to reduce compaction and wheel slip on the brash hills.”

Tracked machines

Much of the cultivation kit is now lugged with tracked machines, while a fair proportion of the land is direct drilled with the farm’s 6m Horsch Sprinter, equipped with Dutch openers. “We try to get a balance with cultivations. We’ll generally plough in front of spring beans, but direct drill where we can, depending on what field conditions dictate.”

Organic amendments are a further aspect of the soil-improvement policy. Until recently, the farm’s benefited from digestate brought in from the nearby AD plant at Cassington, west of Oxford. “This is no longer available, and we tried compost, but that contained too many contaminants. However, we bring in chicken muck and sewage sludge, and they’re proving very successful,” he reports.

“We’re now removing all the straw off the farm, which sounds hypocritical if you’re aiming to improve soils, but the contribution it makes is limited – it takes so long to break down and locks up N. You can get crops, especially cover crops, established better if you remove the straw and there are fewer slugs.”

The combination of experimenting with different spring and cover crops, bringing in new techniques, with a firm focus on soil improvement, is making steady progress, Toby reckons. “The soil is your biggest asset, and you have to get it working for you. It’s a challenge with this Cotswold brash, but we’re seeing real improvements with the steps we’re taking – the land travels better and we’re achieving improved establishment. That’s not across the board, and it’s a work in progress, but we’re getting there.”

Robust approach may well pay dividends

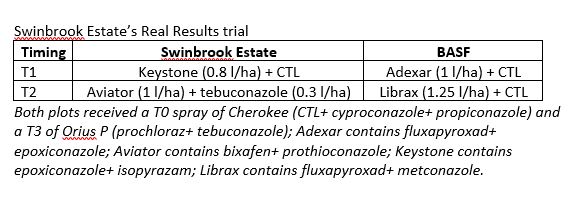

The 11.35ha BASF Real Results field sits high above the rest of the farm, with a relatively kind sandy clay loam in limestone brash supporting the RGT Illustrious wheat that follows OSR. Side by side in the field are the two tramlines under scrutiny – one treated with the farm’s usual fungicide programme, and the other with Adexar and Librax at the T1 and T2 spray timings respectively (see panel below).

The crop’s ready to harvest, but Toby admits he’s not seen a difference between the two plots throughout the season. “I do see better disease control from SDHIs however, and I’m interested in trying different approaches. It can be a pain in the backside to manage this sort of in-field trial, but it gets you to focus your mind if you’re spraying and combining the areas separately. No one else is farming your farm, so the only way to know what works best is to do proper trials.”

He looks after the agronomy himself on the wheats, with Skyfall, Graham, Reflection and Crusoe being the other varieties grown this year. “We’re not a 10t/ha farm – on average wheat yields are more like 8.25t/ha, so we have to use the appropriate product for the job.”

His strategy is to start early and to keep the crop clean. “If you let disease get into the base of the crop early on, you have to hold it there and stay on top on it – fire-fighting in this part of the world just doesn’t work. With the weather rarely offering you the ideal conditions to spray, that puts the emphasis on those early timings,” he explains.

He’s a firm believer in SDHIs. “They each have their own strengths, and are becoming more important as the efficacy of triazoles diminishes. I’d start with a solid T0, then at T1 bring in an SDHI mix that’s good on rust, or add a strobilurin. Septoria is the main disease threat in the Cotswolds, though, and that’s what you’re aiming to keep out.

“The other important aspect is to retain green leaf area and this year has been a case in point. It’s been very dry and wheats in the area definitely suffered – leaves were curling. There’s been relatively little disease, but we maintained a fairly robust fungicide programme nonetheless. We even added some extra tebuconazole at T2 to pep up septoria control, and to be honest, I wonder whether the T2 Librax was on the robust side.”

So did the fungicide help? “It’s hard to say, but our Illustrious stayed greener far longer than most wheats in the area, and remained free of disease when the rain came – there was a long wet period after the T3 sprays went on. So it’s best to keep an open mind.”

All 50 of the Real Results trials have now been harvested and results are being analaysed and will be published later in the year, says BASF’s Ben Freer. “It’s a credit to all the growers who have taken part that not one trial has failed. Managing on-farm trials to ensure you get a reliable result is a skilful job.”

This starts right at the outset, and Ben has some advice for those considering on-farm trials. “First of all, don’t bite off more than you can chew. Choose two or three criteria you’re looking to trial and do them well. Trials can be difficult enough to manage and bring to harvest without overcomplicating things.”

The field should have as little soil variation as possible. “When you’re marking out your tramlines, make sure you’re being fair, so try to ensure the good patches and bad spots are spread evenly between the two areas. Then remove as much background variation as you can – make treatments on the same day under the same conditions, for example,” Ben advises.

The Real Results Circle

Farming in the UK has never before been confronted with such a perfect storm of uncertainty.

Uncertainty over where the industry is headed post Brexit; uncertainty of returns, because of fluctuating prices and stagnating yields; uncertainty over the removal of chemical active ingredients from the arable toolkit, and uncertainty over which of the mind-boggling array of new products, technologies and tools would be best to try to get to grips with.

To combat growing uncertainty, BASF and CPM are encouraging everyone with a passion for UK farming to unite. We want to help form an agricultural knowledge network of experts, industry specialists, agronomists and farmers.

We want farmers to share their knowledge and conduct on-farm trials. By coming together to face challenges as one, we can find out what really works and shape the future of UK agriculture.

This year, BASF’s Real Results Circle is exploring wheat fungicides and oilseed rape profitability. This series of articles in CPM profiles some of the growers who’ve joined the Real Results Circle, giving an insight into how they optimise returns from their crops. We’ll also have topical advice and expert guidance from ADAS on how to get the best from on-farm trials.

To keep in touch with the progress of these growers and the trials, go to www.basfrealresults.co.uk