Bringing together the building blocks of a farming system forms the focus of activities at Forrest Farms in Suffolk. Once in place, using the best available technology brings results, as CPM finds out.

I know that soil health is at its optimum, and the crop will be given every chance to perform.

By Tom Allen-Stevens

From the moment you arrive at the buildings of Forrest Farms, near Stowmarket, Suffolk, you know the farming operation you’re about to see will impress.

On one side of the yard, spray operator Richard Farrow has drawn up the Agrifac self-propelled sprayer with its 5000-litre tank and 40m booms inside the new, purpose-built spray shed. Opposite, in the remarkably clean and well-ordered workshop, farm foreman Robert Hale and Dale White are putting the finishing touches to the Väderstad Tempo 12-row drill, ready to establish the sugar beet – you sense the quiet air of confidence from a team that’s at the top of their game.

There’s a quiet air of confidence from a team at Forrest Farms that’s at the top of their game.

It’s a standard that fifth generation farmer James Forrest is keen to maintain. “The long-term view for any family business is critical – we’re custodians of the land,” he explains. “It’s my turn now, and I’d hope to leave the land in a better state than I found it. The trouble is, in my case it was in a very good state when I took over.”

His interest is in what he calls the “building blocks” of the 1600ha arable business. “The rotation’s very important – I tend to focus not on individual crops but on what they contribute as a whole. That puts an emphasis on ensuring the soils are at their best, that the field drains are in order and the machinery suited and correctly set to the task in hand.”

The day-to-day decisions on the cropping itself are put together, and have been for 15 years, with strong involvement from Farmacy agronomist Peter Riley. “I’m here to put the icing on the cake,” he says. “I know that soil health is at its optimum, and the crop will be given every chance to perform. That makes decisions such as variety and fungicide choice all the more important.”

Working together as a team, to draw out where those differences lie, is what’s brought them to BASF’s Real Results Circle.

The Beccles series sandy clay loam and Hanslope series chalky boulder clay are easily capable of putting up a wheat crop that’ll bring in over 12t/ha, so the on-farm trials are an integral part of striving towards what will deliver that potential.

“We don’t want yield at any cost, but we’re prepared to spend where we know we’ll get returns, and it doesn’t cost any more to grow a 12t/ha crop than it does for one that’ll yield 10t/ha,” reasons James. “So if you have the opportunity to maximise yield, you don’t want to stifle it through poor farming or a poor choice of inputs.”

His farming philosophy has three main strands: “A good rotation is incredibly important. There should be no short-termism, and you farm the soils well – they should be looked after properly.”

Much of the wheat on the farm is grown for seed, and almost all are first wheats. Threaded into a seven-year rotation are winter and spring barley, oilseed rape, sugar beet and spring beans. Parsley was grown for a local processor for the first time last year, and is being considered as a possible permanent addition to the rotation.

“With the wheats, for simplicity we try to grow decent-sized lots of a few varieties. We’re keen to take advantage of new genetics, although some varieties do become good friends,” says James.

A good example is KWS Santiago, which moved from the top wheat slot last harvest to none grown for 2019. “It’s a year to call the changes,” notes Peter. “There are some excellent varieties available on the AHDB Recommended List that yield better and have traits that suit the farm. Gleam is good for early drilling and RGT Gravity has a very impressive and consistent yield performance.” Alongside these are KWS Kerrin, KWS Zyatt and KWS Siskin.

Generations of good discipline, maintaining standards required for seed production, have kept blackgrass at hand-roguable levels on the home farm (about half the arable area). For the most part, this allows a cultivations policy, tailored to soil type, that sets up the crop for maximum productivity.

“We started moving away from the plough about 25 years ago. We still use it where blackgrass remains a problem and for spring crops, although we are trying sugar beet without ploughing this year,” says James. The main cultivation tool is a 7m Väderstad TopDown with a double press, pulled by a Quadtrac and taken to 150-300mm depth, depending on soil type and situation.

Good discipline carries on through every pass over the soils – trafficking is minimised, and the business has long been a strong advocate of the rubber-tracked tractor. At harvest, chaser bins on wide flotation tyres keep compaction levels low, and the team pay close attention to keeping tyre pressures at appropriate levels.

Soil conditioning comes through a range of what James terms “bulky organics”. “We have two large muck spreaders and have applied Limex for the past 30 years. This goes on typically after OSR at 10t/ha for a maintenance dressing or up to 25t/ha if required. But we’re encountering some areas with a high pH now and currently spread about 10,000t/yr of green waste compost, which also helps with potash.”

Straw-for-muck deals bring in another 3000t/yr of organic material, while poultry manure is also applied, generally before OSR establishment. Biosolids have been introduced recently and are used where phosphate levels need building. The result is soil organic matter levels at around 4%, while 2.5-3% is typical for the soil type in the area, reports Peter. “It also delivers on average 96kg/ha of organic N per year, which is unusually high for an arable farm and proof that the strategy’s working.”

Two building-block changes that he’s recommended are to introduce more winter barley into the rotation and a switch to liquid fertiliser. “Most of my clients have now switched over to liquid – the level of precision you achieve is significantly higher. What’s more, the farm is on 40m tramlines, and you don’t need much of a wind to make solid spreading inaccurate at that bout width.”

When it comes to fungicides, the farm follows a similar policy to the approach taken with other inputs. “I wouldn’t want to compromise yields by skimping on fungicides,” notes James.

At this point, Peter pulls out an impressive array of spreadsheets he’s compiled that help him refine the strategy the farm takes. “We’re aiming for big-canopy crops on this farm, and they need good disease control. That warrants using the best technology available, and we match that to the variety and the specific situation.”

An SDHI is used with an azole and chlorothalonil (CTL) at both the T1 and T2 spray timings, with product choice and rate tailored carefully. A multisite is applied at every timing, with a relatively cheap azole applied at T0, while tebuconazole or prothioconazole goes on the ear. “For the past two or three seasons we’ve applied a T1.5 where the situation requires it – either a strobilurin or azole with CTL,” adds Peter.

The farm has been part of BASF’s Real Results Circle for the past three years, and it acts as a useful sense check for Peter. But it’s a progression on a long-standing involvement with on-farm trials – the business is a member and strong supporter of Fram Farmers and the farm hosts variety and fungicide trials run by BASF, notes James. “We have an open day in June. Last year over 200 Fram members attended and were shown round the plots.”

For the second year in a row in 2018, this was also the chance for a look-see at BASF’s new triazole Revysol, adds Peter. “It was a lowish-disease year, although there was still plenty of infection in the control plots. What you noticed where Revysol was used was that the crop was clean from top to bottom, and the levels of green tissue significantly higher. It looks as if it will be a valuable addition to the fungicide armoury, particularly if we lose other active ingredients.”

For James, it will only ever provide the icing on the cake, however. “We’re looking for full productivity across every ha. If you don’t get the basics right, it doesn’t matter how much fungicide you put on, you’ll never turn a poor crop into a good one. Getting things right doesn’t happen overnight and we’re not there yet, but I hope we’ve got the foundations in place that ensure we make the most of new technology.”

The analysis of the ‘icing’ layers reveals the Real Results

Elm Field, cropped with KWS Siskin winter wheat, was chosen for the Real Results trial. This was monitored through NDVI scans provided by AgSpace throughout the season, which show up differences in plant vigour. These revealed growth to be strong and fairly even throughout the season, according to the ADAS analysis.

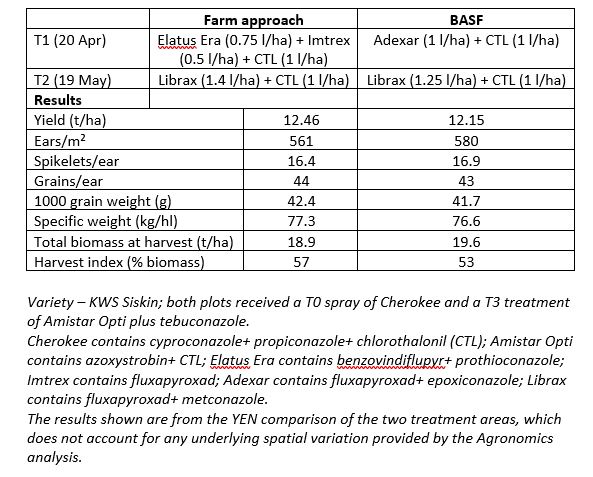

The BASF treatment (see table on pxx) was applied across two tramlines in the northern part of the field and ADAS’s Agronomics approach was then used to compare the results with the farm standard treatment. This uses spatial modelling and statistics to allow yield-map data from the combine to be assessed with scientific rigour.

This analysis, which strips out much of the spatial variation that can undermine results from tramline trials, produced a yield result of 12.8t/ha for the farm standard and 12.66t/ha for the BASF treatment – somewhat different from the weighbridge yields, reports Susie Roques of ADAS.

“Our statistical model indicates that a yield difference of this size (0.14t/ha) could have been due to other sources of variation, which could be soil-related. The difference between treatments was not statistically significant at the 90% confidence level – in this dataset, that would require the yield difference to exceed 0.28t/ha.”

Peter believes the trial shows up the benefit that comes from remaining flexible. “While the yield difference may not be statistically significant, the fungicide programmes themselves were,” he notes.

“It was very wet early in the season and the T1 was delayed – that was why we boosted the application with extra SDHI. This was followed up with a higher dose of Librax at T2. We spent an extra £20/ha, but the weighbridge results suggest a marginal gain of around £50/ha, so on that basis it appears to have paid dividends.”

A disease assessment at GS73 showed the farm standard area had slightly less yellow rust and septoria than the BASF-treatment area. The green leaf areas (GLA) of the flag leaf and leaf 2 were slightly higher in the farm standard area, but GLA of other leaves lower, although again none of the differences were deemed statistically significant.

There were also few notable differences in the YEN analysis of grain characters between the two treatments, notes Peter. “It’s excellent to have this detailed analysis of components of yield, however. One thing it’s shown up is that thousand grain weight fell below the AHDB benchmark, but I think that’s attributable to the low water availability at the end of the season. Otherwise I think this shows the crop was given every chance to perform.”

Local BASF agronomy manager Matthew Keane agrees the results bear testament to the “ultra-professional” approach taken by the farm. “We’ve run trials with Forrest Farms for a number of years, and it’s always proved a good site to demonstrate the differences between various inputs – I rarely leave the farm without having learnt something new.

“The farm standard approach in the Real Results trials reflects a programme that was tailored very closely to the specific pressures of the crop and the season. As such, it shows the Adexar/Librax standard we recommend performs very well and should perform best on most farms in most years,” he adds.

“But I’d encourage every farmer to carry out their own on-farm trial – you don’t have to be one of the Real Results Circle farmers to take part. Suffolk also has a very active On Track farmer group, and it’s this collaboration between farmers that brings about some of the best innovation we’re seeing on farm at the moment.”

- The Stonham open day near Stowmarket takes place this year on 25 June.

Forrest Farms 2018 Real Results trials

The Real Results Circle

BASF’s Real Results Circle farmer-led trials are now in their third year. The initiative is focused on working with 50 farmers to conduct field-scale trials on their own farms using their own kit and management systems. The trials are all assessed using ADAS’ Agronomics tool which delivers statistical confidence to tramline, or field-wide treatment comparisons – a unique part of Real Results.

In this series we follow the journey, thinking and results from farmers involved in the programme. The features also look at some in-depth related topics, such as SDHI performance and data capture and use.

We want farmers to share their knowledge and conduct on-farm trials. By coming together to face challenges as one, we can find out what really works and shape the future of UK agriculture.

To keep in touch with the progress of these growers and the trials, go to www.basfrealresults.co.uk