Technology is revolutionising the way so many things are done, and potato management is no exception. Using the latest satellite imaging, drone technology, monitoring equipment and artificial intelligence some companies are taking potato growing to new levels. CPM finds out more.

It’s about putting control measures in right from the start so you can apply the correct input at the proper rate.

By Melanie Jenkins

When growing potatoes, farmers are able to put years of knowledge and experience into their management – be it their own understanding, that of agronomists or colleagues. But even then, sometimes it’s not enough because of complexities with the crop. However, advancements in technology are changing this.

Having worked in the industry for a number of years, Paul Coleman, managing director of Crop4Sight, along with professional colleagues, recognised shortfalls in the potato crop’s management. “What was apparent was that there’s still a lot of inefficiency in potato production on farm,” he explains. “The reason for this is not because there’s a lack of will and wanting to do better, but because the crop itself is very complex.”

From this realisation he went on to help found Crop4Sight, which is just one of several new technologies now enhancing the management of the potato crop.

Crop4Sight

Crop4Sight is an intelligent software solution that growers can purchase a license to use. It works in a modular fashion, meaning the baseline license can be purchased and extra aspects can be added to it, in a pick and mix format, so it provides the grower with exactly what they want.

The technology uses research and data to untangle the complex interactions when targeting the seed rate of an individual variety from a particular seed stock to get the outcome growers want, explains Paul. “Mathematically it’s nearly impossible to work out your exact seed rate to match contracts, marketable yield, harvest date and physiological factors.”

Having worked in the industry for a number of years, Paul Coleman recognised shortfalls in potato management.

The data sets are on a variety specific level, and this is used to model complex scenarios that are then presented to growers and agronomists in a simple and easy to use format via an online platform.

“Growers are used to planting seeds of a particular variety and knowing, within reason, what the biological yield will be, but this is where the inefficiencies come into play,” says Paul. “Only a certain size fraction of the tubers in a crop are actually marketable yield and that’s what the grower makes money on. It can be very easy to end up without enough marketable tubers by killing the crop off early to stop them getting too big. Or it might be a case that there are too many tubers per plant in the field which are then too small to be marketable.

“So Crop4Sight’s all about precision farming,” he states. “It’s about putting control measures in right from the start so you can apply the correct input at the proper rate and know when to plant, plus what yield and tuber size you’re likely to achieve.

“The platform allows growers to sustainably manage water use by using the platform’s irrigation schedule and growth predictions from emergence through to tuber initiation to dormancy break. The software can also produce critical yield and size forecasting,” says Paul.

It’s been designed it so the platform is easy for the grower to use, he explains. “Growers just put in their planting date and record the date the crop emerges and we can supply a service measuring the ground cover development via satellite images so they don’t have to go to the field to do this.

The Crop4Sight platform can generate seeding rates, irrigation schedules and forecast a yield estimate.

“Then part way through the season the platform can forecast what the yield will be. In this instance, growers would have to dig a 3m length stretch – like they normally would – but instead of having to manually count, weigh and measure the crop our smartphone app can do it for them with a video,” says Paul. “The artificial intelligence (AI) model can count and calculate size and from this it produces a weight for tubers which is extrapolated into total crop size in t/ha.”

And to get irrigation scheduling growers can put in their irrigation parameters, how much water has been put on and the frequency, as well as what regime they want to run. A seven-day forecast of soil moisture deficit will then be produced, explains Paul. “We do have our own rainfall data but growers can choose to input their information if they have a gauge or weather station.”

The supply chain has also adopted Crop4Sights platform, he says. “It allows them to see – with their grower’s approval – how the crop is performing, enabling them to manage supply chain risks ahead of time. It also allows them to manage their own seed stock effectively and decrease time spent in the field through use of automated data collection tools.”

The next step for the firm is to refine the models used and to draw in more research to produce further models. “Our sole aim is to provide the potato industry with an easy-to-use tools to make the right agronomic and commercial decisions at the best time to maximise marketable yield,” adds Paul.

AgroScout

AgroScout was formed in 2017 by Simcha Shore, who has experience working with drone technology from his days in the Israeli army and felt this had the potential to provide aerial imagery for agriculture.

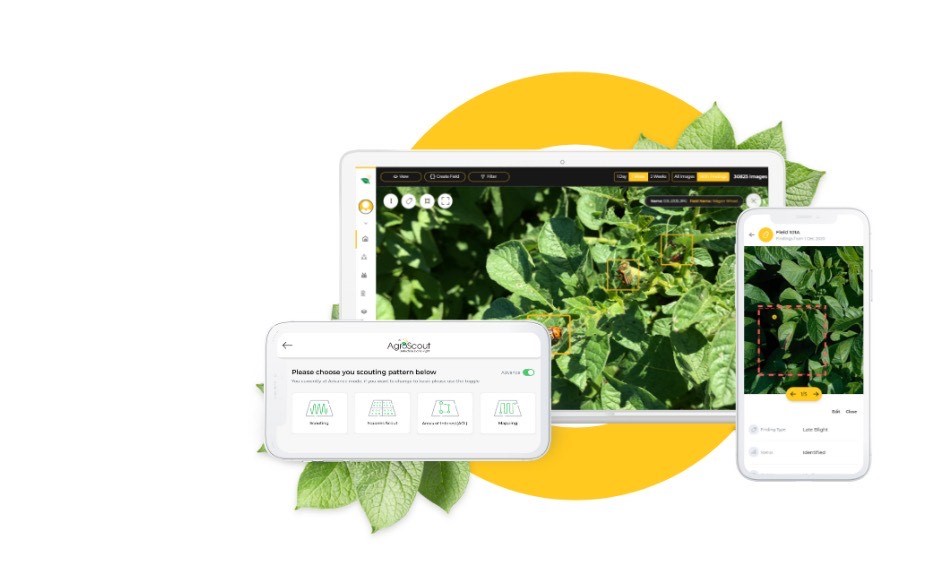

He then went on to create a tool for the agricultural world to improve monitoring and food production, using AI to gain insights from drone, satellite and smartphone data, explains Ioana Lazar of AgroScout. “These insights are presented in reports and on a dashboard to help growers with decision making for growing crops and food processing.”

AgroScout is now a software as a service-based company whereby users can subscribe to a service via a yearly subscription determined on an area basis.

“Traditionally, growers around the world would have to walk a field to crop monitor and inspect fields visually, sometimes on a daily basis,” says Ioana. “But with the current needs of food production, growers are being asked to produce more food, more efficiently all while securing yield and quality.”

But using tools like AgroScout, growers can now monitor fields using mapping, imagery and sensors to get remote real-time updates, she says.

One of the services offered by AgroScout counts plants one by one using drone images.

According to Ioana, the biggest advantage of AgroScout is that it’s partnered with commercial drone company, DJI, meaning growers can affordably purchase a drone to capture data. “It’s very accessible and most growers who have a drone realise what a good tool these are as they can cover 30-50 times the surface area that could be assessed on foot. A human might look at 150 plants in 20 minutes, but a drone can cover 5000, giving growers more time and information to act upon.”

The services offered by the firm cover the full season, from planting to harvest. Typically, monitoring starts with land preparation and provides a review in readiness for seeding. Once a crop is planted AgroScout emergence evaluation counts each plant using images taken by drone, explains Ioana. “From this, the grower can adjust their yield prediction.”

During the growth period the AI analytics help growers to identify numerous pests and diseases in the crop. “We have an advanced tool for this where the algorithm can automatically detect the pest or disease and pinpoint exactly where the issues are, so growers can react accordingly.

“A further tool, ‘canopy coverage’, precisely identifies the growth stage of plants,” she says. “This type of monitoring lets growers know when crops reach maturity so that they can effectively harvest it without losing money by maintaining the plants for longer than they need.”

All of these tools rely on satellite and drone data. Satellite images are integrated with the AgroScout platform, while the grower uses their own drone to capture and upload images to be analysed. Drones are controlled via the ‘Sky’ smartphone app which controls automatic take-off, landing and flight patterns, explains Ioana. “Pests and disease are monitored from 2m, meaning eggs can be detected. Plant count is done from 30m, and canopy and nutrient observations are from 50-100m.”

Growers can immediately access analytics from images delivered as a report via email or app and this can be shared with the team. Field overviews are generated weekly by satellite imagery which is then complemented by the drone service. The field is overlaid with a traffic light system; green areas are fine, yellow are stress areas and red are problem areas.

Pests and diseases are identified in drone images using AgroScout’s AI software.

“The main goal is to help a grower improve their yield and get a better return on their investment, as well as keeping an eye on sustainability which is a big concern,” explains Ioana. “These tools should help farmers grow crops with the environment in mind. They might be able to reduce their pesticide usage and detect nutrition and irrigation problems as a result of the crop monitoring, as well as improve their efficiencies.”

The next step for AgroScout is to integrate their software with different platforms and agronomic tools. This could include weather monitoring software or tools for smart spraying. “Integrating technologies is part of the drive towards precision agriculture and we want to be part of that world – where our tools work naturally with the other technologies on the market,” says Ioana.

B-hive Innovations

B-hive Innovations’ key product is Harvest-Eye, which is a system that can be retrofitted to existing harvest equipment to provide live information as the crop is harvested. It delivers whole field information rather than having to rely on conventional sampling and washing tubers.

The technology measures the tuber count and size profile of the entire crop and can map variability across the field to provide growers with agronomic performance data which can help with future decision making. Growers can also use the technology to determine performance variations between different varieties.

B-hive Innovations is also working on a number of other projects, one of which is TuberScan, which aims to help eliminate potato food waste. According to Effie Warwick-John of B-hive Innovations: “It can be challenging for growers to understand the performance of the whole crop underground. With TuberScan we are trying to address this lack of clarity.

Vidyanath Gururajan hopes B-hive Innovation can help reduce food and energy waste, increase marketable yield and enhance produce quality.

“We want to arm growers with meaningful data-led insights to make better-informed management decisions based on potato size, count and variation. When developed, TuberScan will help growers to more confidently identify areas of poor performance, when to make all-important burndown decisions, and where growers should target fertiliser and irrigation. All these choices can ultimately make or break a crop’s marketable yield.”

In its current iteration, the TuberScan system comprises of radar, GPS units and an in-field camera which surveys the field throughout the growing season. The project has utilised and adapted field-based technologies that were originally developed for the military – reapplying the knowledge and tools to the arable farming environment.

Vidyanath Gururajan, managing director of B-hive Innovations, says: “At B-hive our core purpose is fourfold: reduce food and energy waste, increase marketable yield, enhance produce quality and add value to farming businesses.

“Placing actionable insights at the hands of growers to minimise wastage supports packers and retailers further along the supply chain and provides additional assurances on the quality of their potatoes, prior to hitting the shelves.”

Another project B-hive Innovations is working on is detecting potato defects that can affect the quality of the plants and reduce their value in the supply chain. Using gas sensing technology, the company aims to detect internal defects in a non-destructive manner before potatoes reach the consumer.

There are few chemicals that are approved for treatment of wireworm and those available are very expensive, explains David Nelson.

A further project looks at protein extraction to provide an additional source of protein from potatoes and add value to the supply chain. The project has developed a valorisation process to use low-grade potato and peelings to extract clean label high-quality potato protein. A factory been built to commercialise this process.

The company has also secured funding to explore new methods of wireworm detection, something which typically goes unnoticed until harvest when it’s too late to salvage the plant. “This funding is a huge boost for our research and development and will ensure real progress is made in countering wireworm,” says Vidyanath.

Wireworm is an issue that affects a variety of crops across the UK, but there are few chemicals that are approved for treatment and those available are very expensive, explains David Nelson of Branston. “New solutions can take years to be approved before launching to market, so developing technologies that predict likely damage levels will help target control measures and reduce levels of wireworm damage to tubers at harvest.”

This article was taken from the latest issue of CPM. For more articles like this, subscribe here.