Maximising pod potential is the key to building yield in oilseed rape, and applying fungicides to the crop at flowering gives it every chance to achieve this. CPM gathers research that looks inside the leaf to determine how.

Where we’ve tried split fields with different fungicide options, the differences have been really visual.

By Tom Allen-Stevens

What a disappointment many oilseed rape crops were last year. But for Syngenta field technical manager James Southgate, it served to illustrate how a crop lays down its yield and what can be done to maximise this.

“Last year, many crops put on good growth in early spring and they looked like they were going to yield well. But at the end of May and into June, we had unusually dull weather,” he recalls.

“The low radiation levels coincided with pod fill which limited yield – unlike cereals, there’s no evidence that OSR can move dry-matter reserves around the plant, so it relies entirely on photosynthesis to put on yield post-flowering. It was simply too dull for pods to reach their full potential.”

While yield benefits from using Amistar in OSR were lower in 2016, this farm-based field trial, photographed on 26 July, produced a 1.4t/ha yield response, with an oil increase of 2.8%.

Syngenta field trials last year bore this out – yield responses were capped with an average response of 0.25t/ha, with little yield difference between fungicide treatments applied at flowering, he reports. “Although what we did see was a boost in oil content where Amistar (azoxystrobin) had been applied.”

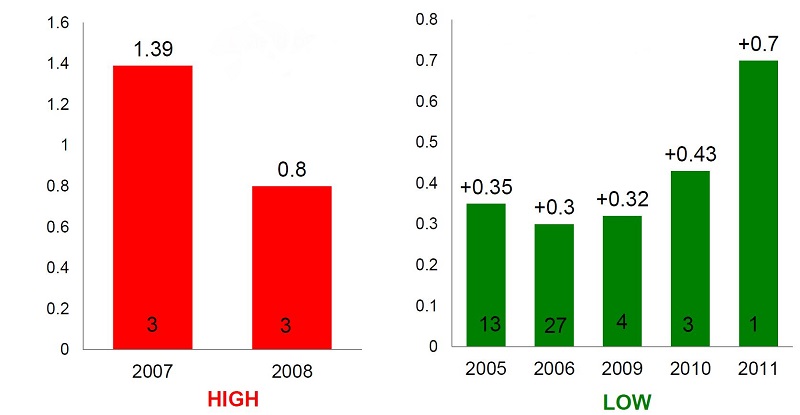

This contrasts with results found in previous years, however (see charts below). “In years with a high sclerotinia incidence, there’s a considerable yield benefit from applying Amistar during flowering, as you’d expect. But we’ve found a yield over untreated of at least 0.3t/ha in years with a low disease pressure,” notes James Southgate.

The OSR yield boost from Amistar

Source: Syngenta 2005-2011; Various Amistar treatments vs untreated; 2007 and 2008 (left) were years with high sclerotinia pressure.

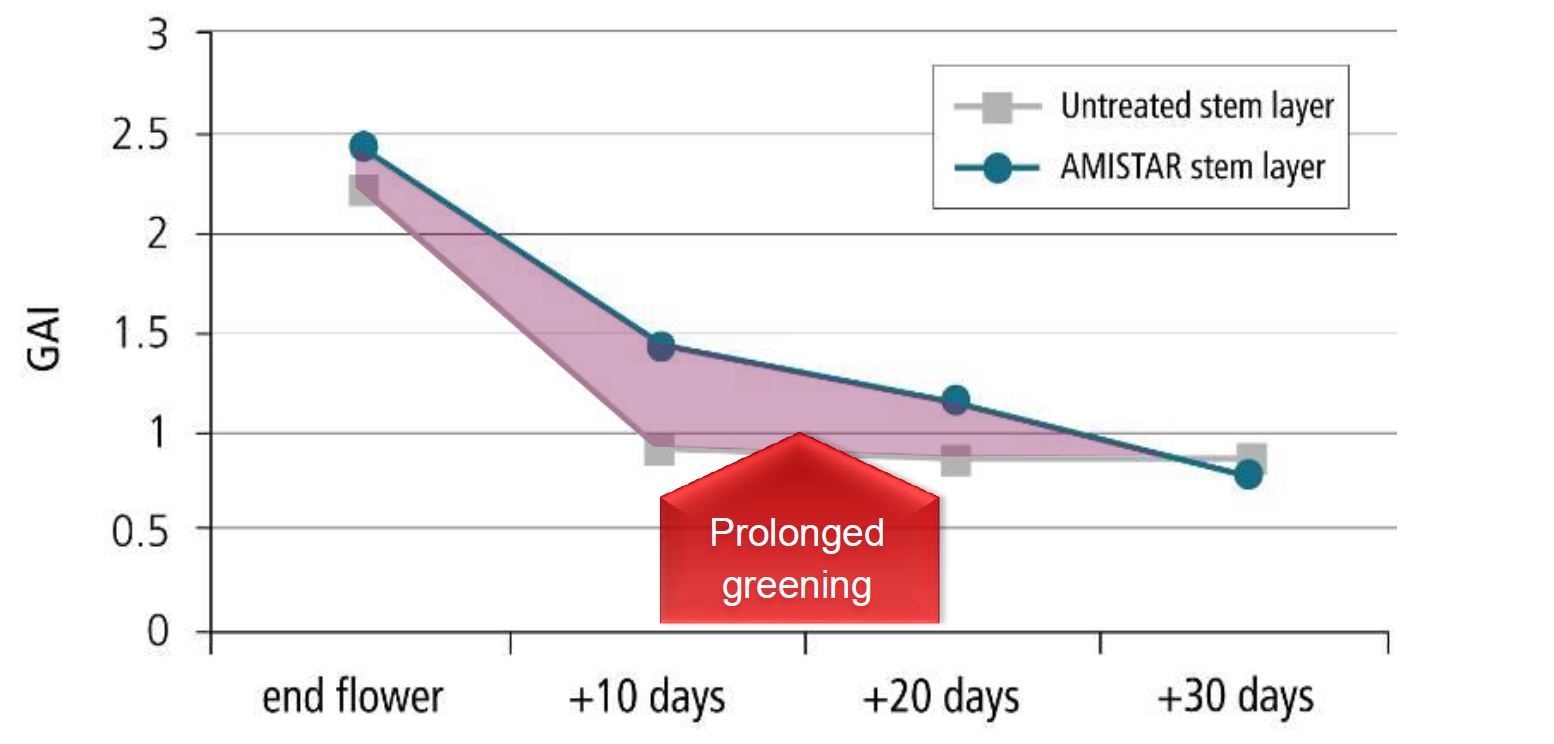

Work carried out by ADAS in 2005 investigated this effect. The green area index (GAI) in OSR from the end of flowering up to a month later was studied (see chart below). Crops treated with 1 l/ha of Amistar at flowering experienced a prolonged greening effect – as much as 0.5 GAI over untreated.

The greening effect

Source: ADAS 2005; Amistar sprayed at 1 l/ha at early flowering

So exactly what’s going on? Dr Jörg Leipner is Syngenta’s scientific specialist in abiotic stress management, based at the company’s research centre at Stein in Switzerland. “Work on Amistar was initially carried out by colleagues at Jealott’s Hill, but more recently we’ve been looking at the secondary effects of the next-generation fungicides – SDHIs have similar properties,” he notes.

In addition to control of the late foliar diseases that kill off leaves early, Amistar is working inside the leaf to offset the effects of natural environmental stresses on the plant that cause premature senescence, he explains.

“A plant produces very reactive, destructive oxide molecules, known as free radicals or active oxygen species (AOS). Normally, low levels of these are produced. But when a plant is stressed, as a result of drought or pathogen attack, for example, considerably higher levels of toxic superoxide molecules are generated.”

These have been found to bring about a loss of green leaf area and early senescence. “To combat this, leaves produce superoxide dismutase (SOD), a powerful antioxidative enzyme, from normal physiological activities, such as photosynthesis, respiration and from exposure to abiotic or biotic stress factors. This enzyme is the primary scavenger of superoxide radicals and is deemed likely to be central in the plant’s defence against toxic accumulation of AOS.”

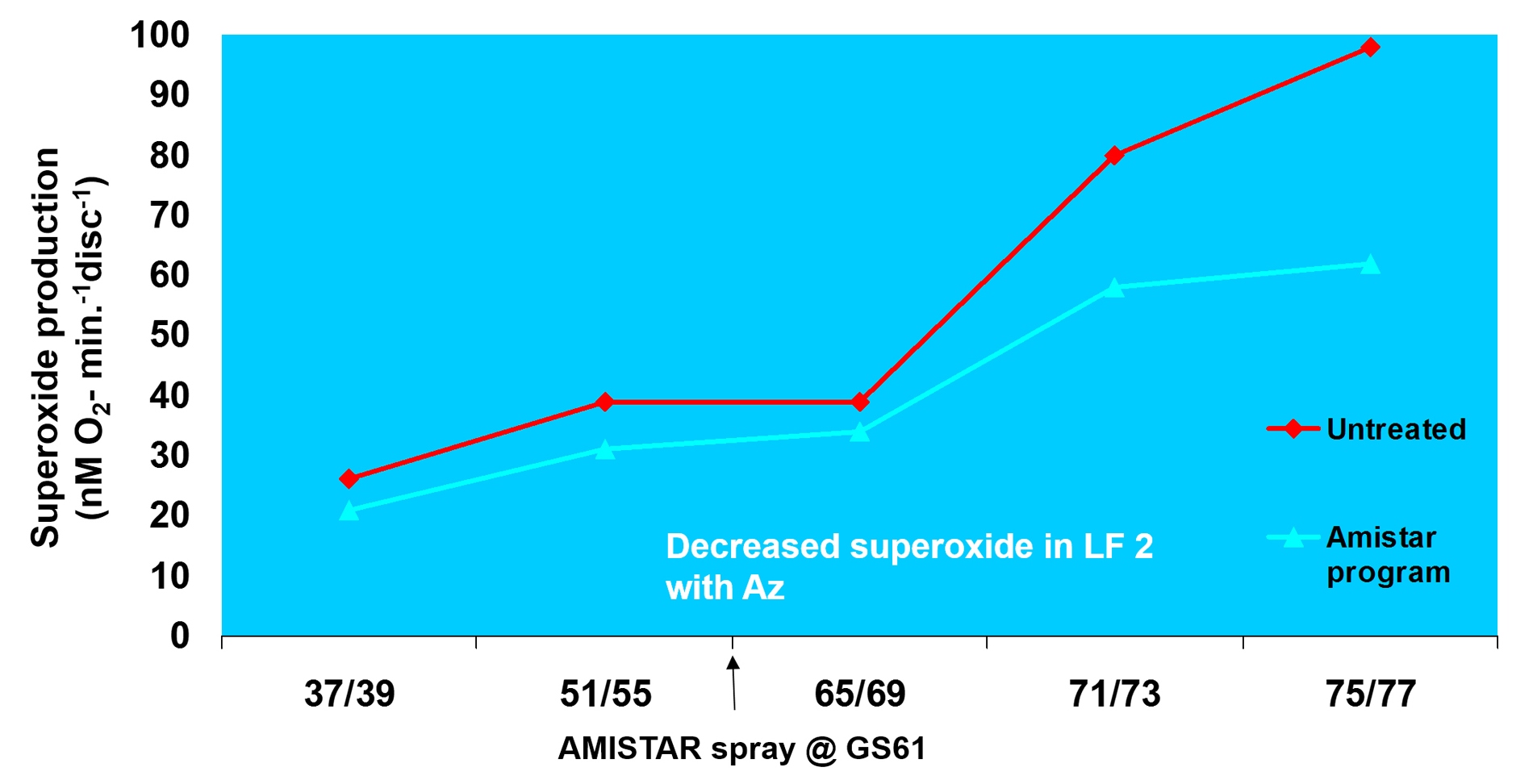

A number of published and scientifically reviewed studies have indicated that azoxystrobin significantly enhances SOD activity in leaves and consequently suppresses the superoxide radical accumulation in leaf tissue (see chart below). Researchers have also found visibly lower foliar damage, where fungicide-treated plants were exposed to injurious doses of ozone.

The physiological effects of Amistar

Source: Wu and Tiedemann, 2001; tests performed on wheat, cv Nandu

Further research has shown that Amistar can help plants improve the uptake and assimilation of nitrogen, as well as effectively regulate water use by the leaf. “A plant can open the stomata, or pores on its leaf, more than is needed. This can affect the finely regulated carbon dioxide and water balance,” continues Jörg Leipner.

“Amistar has the effect of adjusting the stomata, so conserving water when supplies may be limited. This protects the plant from the effects of drought stress and helps it remain more photosynthetically active right through to the point of natural senescence.”

So in the field, it’s the green leaf growers should look to preserve, advises James Southgate. “An application of Amistar at yellow bud to early flowering is the best timing to prolong the green leaf area. But recently, sclerotinia pressure has tended to increase later in the season with applications at mid flowering giving the best disease control.

“You’ll still get the greening effect at the later timing, although to a lesser degree on leaves as the flowers and pod canopy will intercept more of the product. Field trials have shown the improved plant health it brings also helps combat the effects of verticillium wilt.”

Symetra (azoxystrobin+ isopyrazam) includes an SDHI, offering extra persistence against sclerotinia where disease pressure is very high, he adds. “The isopyrazam sits in the wax layer and releases slowly into the leaf, protecting the plant for longer and helping to prolong the greening effect.”

Grip and penetration give Amistar the edge

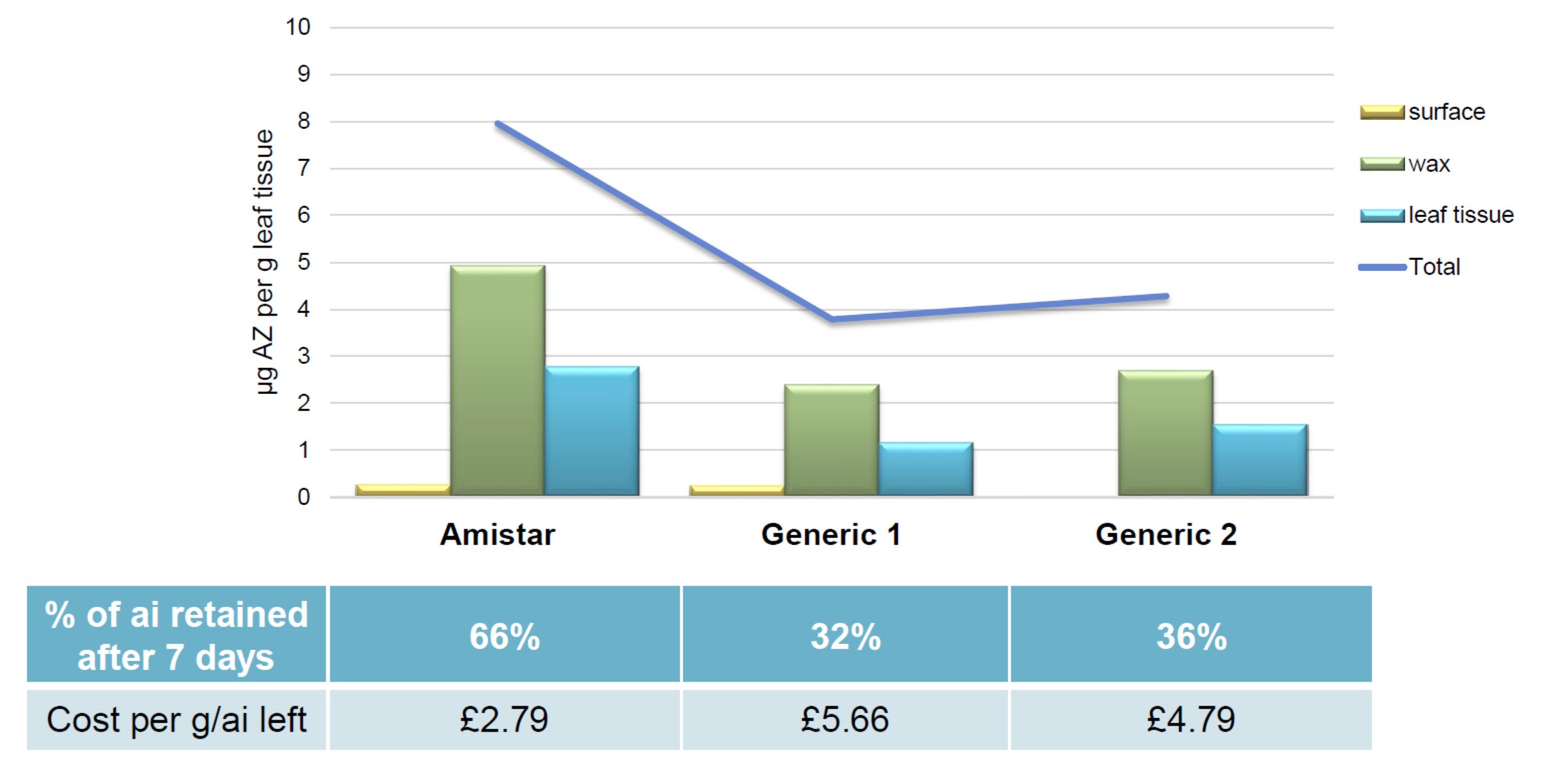

You may apply a fungicide to an oilseed rape crop, but how can you be sure it’s actually doing the intended job? “Chemistry that sits on the leaf surface can only provide protectant activity against pathogens,” notes Syngenta’s head of technical, Dave King.

“If you want to take advantage of its curative ability, it must be formulated in such a way it penetrates the waxy surface and can get to the leaf tissue. To have any greening effect, a fungicide can only do this if it’s inside the plant. What’s more, an OSR leaf has a very thick waxy layer, presenting an extra formulation challenge.”

Work was undertaken last year at Jealott’s Hill to investigate this, he reports. “We wanted to look at how Amistar compares with generic azoxystrobin formulations, both in terms of how they stick to the leaf surface and their penetration through the waxy layer.”

To test retention and rainfastness, OSR leaves were sprayed with the three products, then some plants were shaken, while others were subjected to the rain machine for one hour – this is a room that simulates heavy rainfall under controlled conditions.

“Amistar performed well in both situations, but interestingly one of the generics showed poor leaf retention – the spray just rolled off the leaf. And the other generic washed off the leaf in the rainfastness test,” reports Dave King.

To find out where the chemistry goes, scientists carried out a partitioning study. “This is where the amount of chemical that’s penetrated each layer of a leaf is assessed at various stages after treatment, from a few hours to a week. That gives a measure of persistence, as well as an idea of where it’s active,” he explains.

Amistar was found to be the most persistent overall, and the study showed it was taken into the waxy layer quickly, from where it was conveyed gradually into the leaf tissue (see chart below). “Too much of the first generic material stayed on the leaf surface, but the chemical that moved into the wax showed good persistency. The other generic was taken up quickly into the wax layer but had poor persistency,” he reports.

Azoxystrobin present in leaf tissue seven days after treatment

Source: Syngenta tests carried out at Jealott’s Hill, Berks, 2016

“To get value for money from azoxystrobin, it needs to be in a formulation that’s taken up by the waxy layer quickly, from where it should be released gradually into the leaf tissue. Amistar’s persistence has been shown to be around three weeks,” concludes Dave King.

Origins of a legendary fungicide

It was sometime during the 1960s that a scientist in Eastern Europe noticed a curious phenomenon in certain mushrooms found growing naturally in woodland. No other fungi grew near them, and it was deduced this was down to a compound, called strobilurin, the mushrooms produced as a natural defence mechanism.

But it was at Jealott’s Hill, Syngenta’s Berks-based research centre, where the real breakthrough occurred. The main problem to be overcome was that the natural compound was unstable in light, so a specialist team of scientists spent 50 man years synthesising 1400 experimental compounds in search of a product that could be used in the field.

Eventually they found a synthetic analogue that was not only more stable, but simpler to make and more active, and azoxystrobin was launched as Amistar in 1997. The fungicide was quickly adopted across a broad range of crops and it became the most widely used globally – sales grossed $1.3 billion in 2011 alone, while it’s cleared for use on 120 crops across 100 countries.

What set Amistar, and other strobilurin fungicides, aside from previous chemistry were the physiological benefits seen in the field. With its introduction 20 years ago, farmers and agronomists reported a “greening” effect, which appeared to delay the senescence of treated crops. Yield increases were attributed as much to this as to the efficacy of the new compounds against disease.

In 2002, however, septoria isolates were found in UK wheat crops that had developed a mutation conferring resistance to the single-site chemistry. The mutation quickly spread and soon strobilurins fell out of favour as farmers’ mainstay defence against the number one disease in wheat.

But Amistar has retained its efficacy across a broad range of pathogens in so many diverse situations it remains farmers’ favourite fungicide overall. Research into the physiological benefits in particular has continued, both at Jealott’s Hill and at Syngenta’s European headquarters near Basel in Switzerland. This has refined understanding of how a plant is subjected to biotic and abiotic stress, and how Amistar helps overcome this.

Greening power secures place for Amistar

The predominantly ironstone soils of the two farms managed by Rufus Dudfield, near Banbury in Oxon, do have good yield potential. “That’s if crops are well established and the weather gods are kind,” he reports.

But they’re inclined to dry out quickly and crops can rapidly become stressed by lack of moisture, heat and nutrients. So for the farms’ 250ha of oilseed rape, Amistar (azoxystrobin) is seen as a key tool to keep plants green and healthy for as long as possible through the season. “Where we’ve tried split fields with different fungicide options, the differences have been really visual, and the yield results have always shown the benefit of including the Amistar,” he adds.

Rufus Dudfield has tended to sow OSR at higher seed rates to combat the damage from slugs and flea beetle. The result is a crop with a higher green area index (GAI), and he’s keen to make best use of this.

“Last year, for the first time, we tried Toprex (difenoconazole+ paclobutrazol) as a growth regulator specifically to encourage side branching and greater leaf area. It really worked and the result was striking. If we can build the plant structure to develop more leaves, it’ll make even better use of the Amistar green leaf retention,” he says.

Typically, he’s used a split dose of Amistar timed at early and mid-flowering. Last year, however, the early Toprex application was followed with a single, higher-rate application of Amistar. A reduced rate of prothioconazole was included in the early flowering treatment as a guard against the high incidence of light leaf spot.

Amistar has always given Rufus Dudfield reliable sclerotinia control, he reports, and even if there’s no disease, the control of late foliar diseases and the health of plants has kept the crop noticeably greener. “We get the ups and downs of OSR yields like all growers, but I do believe Amistar helps us to be more consistent year-on-year with yields and, importantly for oil content, compared with others.”

German lessons

The experiences of German oilseed rape growers, learned during study tour to Westphalia last year, encouraged Sutton Estates’ Chris Baylis to let 50ha of the farm’s 550ha OSR crop in Lincs die off naturally last harvest, instead of the normal glyphosate desiccation. The result was a 0.5t/ha yield increase across the untreated area.

“There was an impression from German growers’ practice that we may be too quick to kill off the green leaf and that could be cutting yields, which our experience last season would suggest was the case,” he says.

The undesiccated crop received the farm’s routine two-spray Amistar programme for disease control and green leaf retention. This was harvested just two to three days later than the area treated with glyphosate. Although the stems were greener, with the help of a Podstick application, the crop was easy enough to combine, albeit a little slower, reports Chris Baylis.

He acknowledges crops may have benefited more than normal from an extended green leaf area last summer, helping them compensate for the extremely low sunlight levels during the dull June. “Glyphosate will still remain crucial as a harvest aid for some crops and to manage the combining workload. But for clean, free-standing crops there may be greater opportunity to leave them to reach their full yield potential,” he adds.

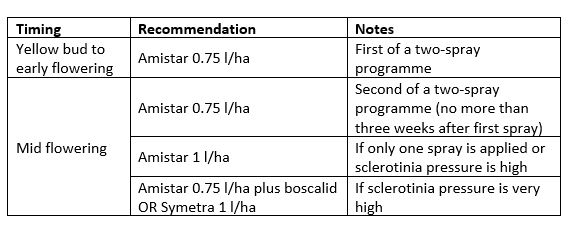

Flowering fungicide recommendations for oilseed rape

Use forecasting tools and local information to assess sclerotinia levels; Adding an azole may be advisable at the earlier timing if light leaf spot pressure is high. Source: Syngenta

Research Briefing

To help growers get the best out of technology used in the field, manufacturers continue to invest in R&D at every level, from the lab to extensive field trials. CPM Research Briefings provide not only the findings of recent research, but also an insight into the technology, to ensure a full understanding of how to optimise its use.

CPM would like to thank Syngenta for sponsoring this Research Briefing and for providing privileged access to staff and material used to help bring it together.

Syngenta is committed to the continued R&D of both existing technologies and new products to help farmers get the best from every application and make more efficient use of resources –– to grow more from less.

every application and make more efficient use of resources –– to grow more from less.

Syngenta invests around £1.1bn a year in global agriculture R&D. These advances enable more effective ICM programmes to create profitable and sustainable intensive farming systems, now and in the future.