Oilseed rape is a notoriously difficult crop to perfect, with some of the key issues highlighted in a study carried out by Dupont and CPM. But a well rounded fungicide programme can be a useful tool.

Growers really need to mix and match chemistry to tackle disease resistance.

By Charlotte Cunningham

Undeniably, the past few years have seen oilseed rape gradually slip off the map. Grower numbers have declined, largely driven by high costs, disease pressures and growing concern over efficacy and availability of chemicals. However, with new and improved options making their way onto the market – in combination with significantly higher market prices – could OSR regain the ground it’s lost?

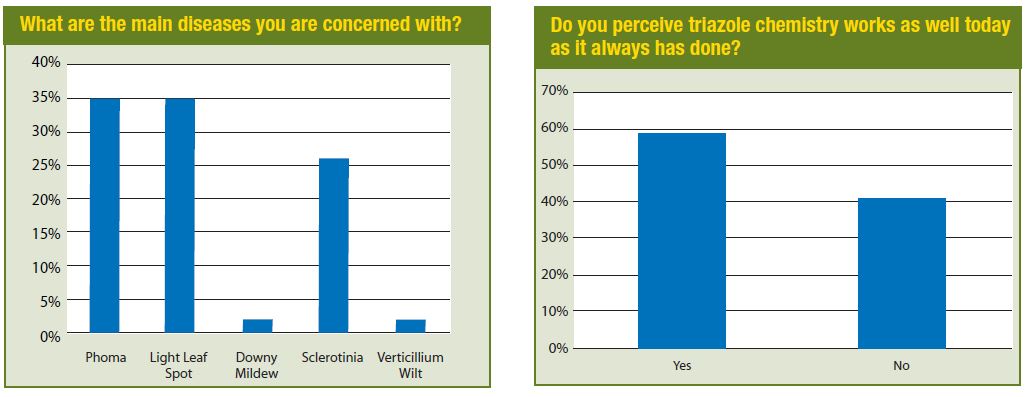

Alongside the weather, disease pressures pose one of the biggest threats to arable farmers. In a recent survey conducted by CPM and DuPont, phoma and light leaf spot came out as the top disease pressures – with 35% of growers rating them as their number one cause for concern (see chart below).

“What strikes me is, historically, phoma would have had the greater share of concern,” says Mike Ashworth, product manager at Dupont. “LLS was traditionally only seen in the North – however, this is no longer the case, with the disease now noticeably spreading across the country.”

Yield-robbing disease

According to AHDB, losses from phoma are around £100 million each season, whereas LLS is estimated to cost up to £160 million every year, reflecting just how severe LLS pressures have become. “Thinking about the establishment stage, phoma is the first yield-robbing disease growers come across,” says Paul Cartwright, crop production specialist at Frontier. “And with more incidents of LLS further south, it’s something that growers need to be guarded against.”

While worries over sclerotinia are still prominent, the concern is less severe, with only 26% of farmers stating this as their main cause for concern. This is largely due to pressures being more localised, with the disease often associated with farms with a previous history, explains Faye Ritchie, plant pathologist at ADAS.

“Concerns over sclerotinia aren’t a surprise, as we’ve seen yield losses of up to 50% in crops without fungicides or where fungicide applications were applied too early or too late in relation to flowering,” she adds. “However, losses are less frequent now with better timing of fungicides and using two-spray programmes on high-risk farms.”

It’s unsurprising to see very low levels of concern over downy mildew and verticillium wilt, says Mike. “For the vast majority of growers, these diseases aren’t a major problem. It’s incredibly rare for either of them to have an economic effect.”

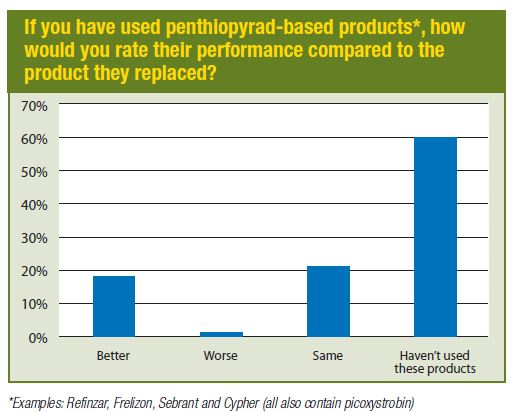

So how can growers tackle these ever-growing disease pressures? As LLS becomes more of a concern, targeting the disease effectively has never been more important. For years, triazoles have dominated the market as the go-to product choice, and they appear to be upholding their long-standing reputation. Some 59% of farmers believe triazoles are as effective today as they’ve always been. But it can’t go without mentioning that 41% believe they’re not as effective (see chart above).

“From a scientific view, the sensitivity of LLS to triazoles has declined,” says Mike. “It’s not quite what it used to be and so growers need to be looking at other options.”

Interestingly, it’s not just the decline of triazole performance heightening disease concerns, explains Faye. “The weather is a big factor in LLS epidemics,” she says. “In autumn 2015, we found it in fields in early Nov and favourable conditions resulted in an epidemic that was difficult to control – whereas the disease appeared later than that in late 2016 and has been less severe in some areas. Incorporating other methods such as using more disease-resistant varieties can help to manage both phoma and LLS more effectively.”

Of course, this doesn’t mean that triazoles don’t have a place in the fungicide programme, but growers need to be responsible with their usage to protect the chemistry, says Mike. “LLS needs a number of fungicide applications,” he explains.

“This can’t be achieved without triazoles. They’re part of the solution and still have good efficacy – it’s crucial to match the chemistry while triazoles still work.”

However, triazole resistance is an issue for LLS control, warns Paul. “To get the best out of them, growers need to be using products at the right time. What we don’t want to see is triazole efficacy completely drop off – they’re a prevalent chemical in the OSR armoury.”

The need to protect chemistry by using alternative products has led to the introduction of non-triazole options like Refinzar, Frelizon, Sebrant and Cypher. Comparing the performance of these new products to the one they replaced, 98% of farmers who’ve used the alternative believe they’re as good if not better (see chart above).

“It’s very encouraging to see results like this,” says Mike. “It indicates that growers have introduced resistance management into their programmes.”

This has also been demonstrated in the AHDB-funded OSR fungicide trials against LLS and phoma, where performance of azole and non-azole products has been similar, recalls Faye.

Interestingly, however, 60% of farmers are yet to try these products. “Growers really need to mix and match chemistry to tackle disease resistance,” says Mike. “There are many benefits of these products – such as improved rooting and better establishment – as well as having a break from triazoles.”

Which is the closest to your view on resistance management when choosing a product?

With such a large proportion of famers not using these products, this increases the risk of resistance, warns Paul. “The challenge comes when growers stick to what they’ve always used as they’re happy with the level of control they have. If timed right, there’s no reason these products won’t offer the same level of control growers see from triazole-based alternatives.”

Increasing chemical options mean it’s now more viable for growers to move away from solely triazole-based programmes. “Previously, every other chemical to target LLS has been triazole based – nothing could compare,” says Paul. “But now there are alternative options. It’s everyone’s responsibility to protect the chemistry we have available to use – resistance management is key.”

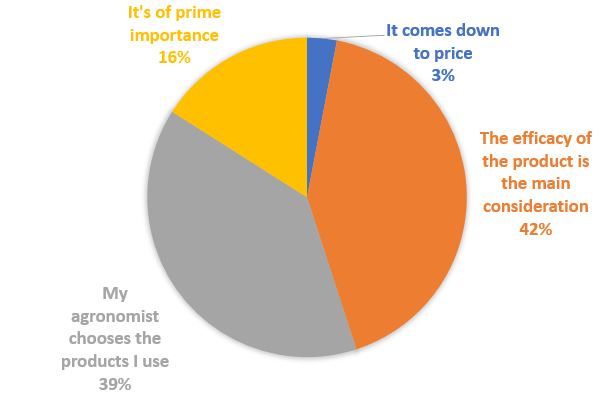

So what sways farmers to opt for a certain product? While Mike believes resistance management is the biggest benefit of non-triazole products, interestingly, only 16% of farmers believe this is of prime importance when it comes to choosing a product (see chart above). Perhaps unsurprisingly, efficacy came out on top, with 42% of farmers revealing this is the main consideration for them. “Until growers have a bad experience, they won’t buy in to resistance management,” explains Paul.

Of course, efficacy and resistance management do often go hand-in hand. The prolonged use of a product with a single mode of action is known to increase the risk of resistance, resulting in poor disease control, says Faye. “In the case of azoles, efficacy is decreased as mutations that cause decreased sensitivity are acquired and erode the performance against target diseases,” she explains.

What is your view of using the benefit that the SDHI prenthiopyrad has in enhancing rooting OSR?

Resistance management

“We need both azoles and non-azoles for control of phoma and LLS and for fungicide resistance management strategies – so the inclusion of a range of chemistry in fungicide programmes is important if we want to maintain control in the future.”

However, disease control comprises more than just chemicals, adds Paul. “A lot more people are now considering variety choice as a method of control. Opening a can of product should be the last thing you do – from a disease point of view, growers have a lot of good tools at their disposal.”

One of the biggest challenges of growing OSR is that a lot of money is put into the crop at a very early stage, from which there could potentially be no benefit, notes Mike. “There’s a lot of front-end loading of expenditure when growing OSR. Therefore, establishment and survival is essential to ensure early investment isn’t written off.”

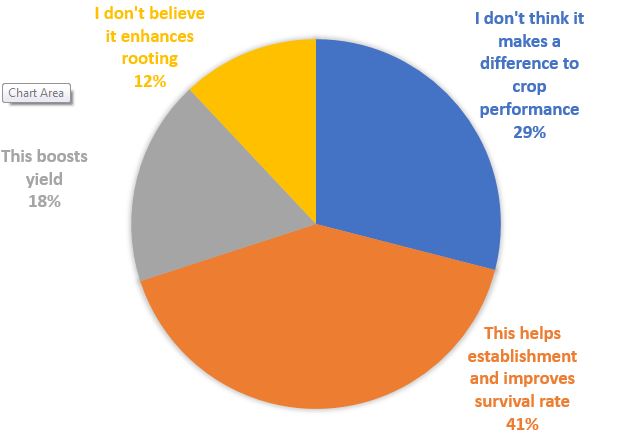

Due to the inclusion of the SDHI penthiopyrad, products such as Refinzar have proven to aid the rooting of OSR plants. Encouragingly, 41% of farmers agree these products help establishment and improve survival rate (see chart above). But perhaps surprisingly, 29% believe it doesn’t make a difference at all to crop performance.

“One needs to consider why OSR has underperformed,” explains Mike. “There may be a number of other factors that are limiting performance. For example, cabbage stem flea beetle pressures make OSR very hard to grow in some areas, but outside of these pressures, these products remain a great choice.”

On top of improving establishment and crop survival, a further 18% of growers believe the SDHI component helps to boost yields, though this is likely to be a result of improved establishment, says Paul. “A nice, big root system will help the crop to establish much better,” he says. “If a crop is better established, you would anticipate a larger yield potential.”

Be on the front foot for phoma and LLS

So, what are the main considerations to maximise disease control? The real key is that prevention is better than cure, says Paul. “Products work better when they’re applied ahead of disease. It’s crucial to understand disease risk and time applications appropriately. This year, growers will need to be on guard against disease given the especially wet start to Aug.”

Faye agrees: “Fungicides to control phoma leaf spot are usually applied in response to a threshold observed in crops in the autumn. Aim to apply fungicides when 10-20% of the plants are affected – with a further application when re-infection is observed.”

Using a variety of products and having a sound awareness of disease pressures are vital, says Mike. “Look at your geography and think about what the likely threat levels are in terms of disease. Look for broader warnings such as results of spore trapping in phoma.

“Agronomists and growers are facing constant difficulty to maximise LLS control as they ideally need to spray in Jan and Feb but conditions can make this impossible, meaning there’s often an 8-12 week gap between applications,” he explains.

“A lot of thought should be given to autumn applications as to what rates are used. Timely applications of a suitable rate of product offer growers the best form of protection as well as helping to break resistance to triazole chemistry.”