Losing precious OSR seed in the field due to the weather and header losses has consequences that go beyond yield loss. CPM explores the options to help keep seeds in their pods.

The problem arises from the swelling of ripe pods in wet weather, which then contract in dry weather.

By Lucy de la Pasture

Pod shatter is a natural process for seed dispersal in oilseed rape, but on farm it can result in significant seed loss caused by wind and rain, or the combine passing through the crop.

But yield losses aren’t the only consequence of pod shatter, explains Dekalb technical specialist Will Vaughan-France. Perhaps of greater significance is seed return and the problems it can create with volunteer OSR in subsequent crops and OSR population management. Often shed seed may mean there’s more OSR seeds in the seedbank than is sown, he highlights.

Volunteers also provide a green bridge for problem pests, such as aphids and cabbage stem flea beetle, and are in the ground at a time when soil temperatures are warm enough for club root to thrive, he adds.

In many cases pod sealants and the pod shatter resistance trait can complement one another.

Will explains that pod shatter losses can exceed 70% after adverse weather (such as hail or high winds) or where harvesting is unduly delayed. In NIAB-TAG delayed harvesting trials, results have underlined the value of the trait in practice.

“On average, the four Dekalb pod shatter resistance varieties in the trials yielded almost identically to the non-resistant controls when harvested on 23-24 July. When harvesting was delayed for seven days, the non-resistant varieties yielded 6% less than the resistant ones, the gap widening to 9% after a further seven-day harvest delay.

“Even assuming a conservative 4t/ha initial yield, that sort of delay that would be quite normal on many farms with workloads as pressurised and weather conditions as variable as they are today. It represents a yield saving of just under 0.25t/ha from pod shatter resistance, worth around £75/ha in output.

“It’s an important finding because many growers are desiccating their OSR a good week too early in the interests of security, and every day of pod filling lost reduces yields by 1-2%. We also know that seeds accumulate most of their oil in the second half of seed filling, so the gross output losses from harvesting too early for fear of shattering are even greater.”

According to Dr Vasilis Gegas, Limagrain UK’s senior oilseed rape breeder, pod shatter resistance is a trait that’s often under estimated and not really fully understood. “It was originally introduced into OSR from radish as part of the hybrid breeding programme. But, not all hybrids carry pod shatter resistance as the trait was lost in the breeding process to improve the restorer,” he says

“It is now feasible to precisely quantify pod shatter resistance using lab-based techniques where the force required to shatter the pod is measured, and this clearly shows that not all hybrids possess the trait and for those that do, they don’t all offer the same level of resistance, he says.

Innovations such as the pod shatter resistance bred into both Dekalb and, more recently Limagrain, varieties, which enhance the reliability in yield and quality of OSR are always well received by the industry, given the fickle nature of the crop’s performance reliability, says Sarah Ferrie, from Interagro.

But there’s another way to minimise seed loss close to harvest, which is to apply a pod sealant either with, or before, the desiccation spray, she points out.

“Pod shatter, triggered by extreme weather events in the run up to harvest, typically result in yield reductions of between 8-12%, but losses can be much higher as a result of hail storms and heavy rain.

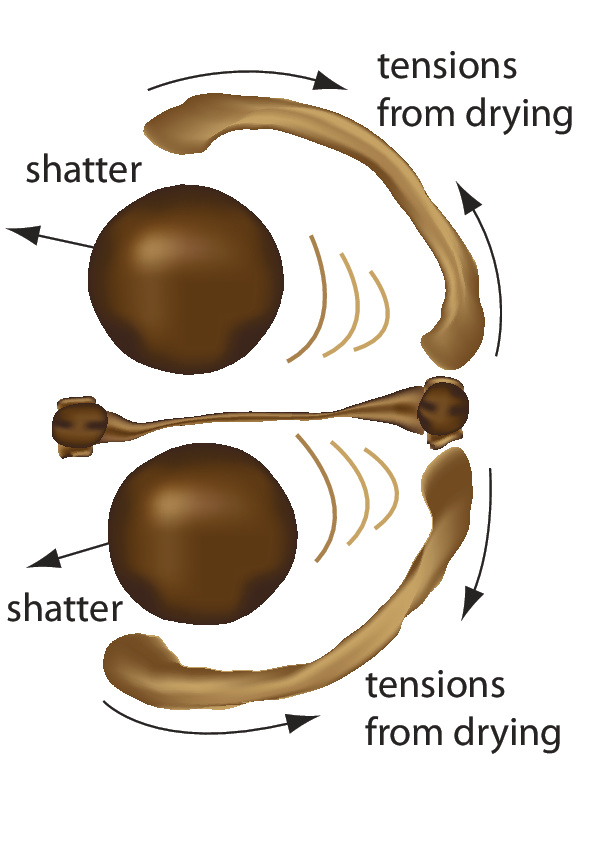

“The problem arises from the swelling of ripe pods in wet weather, which then contract in dry weather. In the run up to a late harvest, brittle over-mature crops are particularly at risk of pod shatter as plants become older and drier with age.”

“Pod sealants, such as Iskay, coat the crop with a thin film of polymer, best described as a micro-mesh, holding brittle pods together to prevent shattering, with sufficient elasticity to allow for the final stages of pod fill and yield-building.”

Agrii Agronomist, Russell Frost, who covers Hants and Wilts, says that genetic pod shatter resistance is a very useful advance, but he believes more knowledge of this trait is needed.

“From what I understand, pod shatter resistance isn’t just present or not, there are degrees of resistance offered by different varieties. We need more understanding of how pod sealants could enhance the pod shatter resistance and harvest management of individual varieties”

Russell has been recommending Iskay as a ‘reliable insurance’ in the 4-5 weeks pre-harvest since it was launched nine years ago. Two thirds of the farmers he advises apply it with their pre-harvest glyphosate, some are using it as a standalone application.

“Pod sealants are now widely adopted as an important part of pre-harvest management. It also offers an indirect route to reducing volunteers in following crops.”

“Whilst OSR volunteers may not usually be considered a problem where OSR is the following crop, they could mean the optimum population for yield of 25-35 plants/m2 is exceeded,” adds Sarah.

Russell also uses a pod sealant to manage harvesting sequence. “To put it simply, if it takes 4-5 days to drill your OSR and 10-days to harvest it. A pod sealant can be a useful management option to help protect later harvested blocks.”

Timing and tank mix flexibility can bring additional gains, he suggests. “Some of my growers apply the product two weeks before the pre-harvest spray because it leaves the pods more rubbery. It also causes a degree of crop leaning in the tramline which seems to help with the subsequent pass of the sprayer with the desiccant.”

When it comes to margin returns, Sarah adds that in Interagro trials, Iskay has delivered yield benefits of up to 0.52 t/ha, worth £140/ha at OSR prices of £280/t.

Managing pod shatter in the field

Christmas trees rarely provide any inspiration for much in life, let alone agriculture. But in a classic example of seeing is believing, it was a Christmas tree more than 20 years ago that convinced Paul Drinkwater that pod sealants were worthwhile.

“At the time, pod-sealants were a relatively new innovation and consequently I took some convincing as to their effectiveness. On the suggestion of the manufacturer, I sprayed our Christmas tree with one of the first pod-sealants and I have been a believer ever since,” explains Paul, company agronomist at Abbots Ripton Farming Company.

Growing roughly 400 hectares of OSR, some of which is heavily exposed to the weather on land at Lavenham Fen, he’s come to regard pod-sealants as a valuable means of protecting crops from strong winds and heavy rains.

With time they’ve moved on considerably and the modern versions are better formulated than earlier generations, but performance varies greatly between brands, so Paul has experimented with many over the years to help him understand which the best are.

“We grow both hybrid and conventional varieties and there’s a case for applying Pod-Stik to them both. Some of the conventional crop is left to mature naturally so it can be saved for seed, I wouldn’t dream of leaving that unprotected.

“Similarly, hybrids benefit just the same. Even those that claim pod-shatter resistance are only moderately less susceptible that those that don’t, so again there’s a benefit from applying a pod sealant.”

The yield savings from reduced shatter losses in the run up to harvest and at combining are hard to quantify because it often depends on the weather in the weeks before combining. But over the years, Pod-Stik has provided peace of mind and brought flexibility to harvest schedule, says Paul.

“Trials suggest a reduction in losses of about 0.5t/ha and that would be my experience, though in some years it is more and less in others, but it’s always positive and economically worthwhile,” says Paul.

Across roughly 150ha of the farm he chooses to grow a Clearfield type variety to enable better weed control, but just as with other varieties, there’s a desire to minimise volunteers.

“Anything that we can do to minimise the safe harbour afforded to slugs is to our benefit and reducing volunteers is part of that plan. But we also want to reduce the herbicide required to control volunteers. Pod-Stik plays a crucial role in achieving both objectives,” he says.

The variable nature of this year’s crops is likely to extend flowering and spread harvest over a longer period of time, so Paul and his team are preparing to manage crops on a field-by-field basis.

“Crops are generally behind compared with last year, but the variability between crops is also frustrating. Harvest will be later than normal, and this means less favourable weather. We need to plan for this eventuality,” he explains.

If applying the product on its own, the standard advice is to spray on at around growth stage 80-82 when pods are fully formed, but still pliable. In a typical season this usually coincides with the Cereals event around mid-June with harvest usually four to six weeks later. More often however, it’s co-applied with glyphosate.

“Our preference is to apply it 14 to 21 days before harvest with glyphosate as this helps manage crop maturity and harvest workload while ensuring crops are protected for the final weeks before combining,” he says.

Hutchinsons agronomist David Shepard based in Kent, believes it’s always better to start with a variety that has pod shatter resistance, especially on exposed sites or if you have a large acreage to cover, but recommends applying a pod sealant, such as Zip pod, to all of his OSR crops as part of a risk management strategy.

“Our trials data show consistently better results from crops treated with pod sealant over untreated – so it doesn’t make sense to risk losing what could be a significant proportion of the crop so late in the season – there’s already a lot of money invested in the crop.”

“I prefer to have Zip pod applied as a separate application, when the crop is still green but the pods are full size – typically mid-June in my area as this is when it gives the best results,” he says.

“Travelling through the crop at that time means that the crop in the tramlines is still flexible which is particularly important for growers without high-clearance sprayers. About 8% of the field is within the tramline on a 24m sprayer,” he says.

“If the crop’s coated with a pod sealant at this timing, then a lot less damage is caused than application in early July, when the crop is ready for desiccation. It’s even more important if the desiccation timing is delayed for whatever reason!

“Another practical bonus to applying all the pod sealant applications in one go is that you can wash out the sprayer straight after and the job’s done. This saves on tank washings, especially if its’ hot and the crop is being desiccated over several days, or if the fields aren’t all ripening at the same time.”

Implications of OSR volunteers

- Seed persistent in soil – quality losses in succeeding OSR crops are felt quickly.

- Provide a feeding reservoir – for slugs and aphids which are responsible for virus transmission.

- Club root – volunteer OSR germinate at the perfect time to perpetuate club root already in the soil.

- More than lost yield – seeds added to the seed bank may lead to difficulties managing OSR populations.