Good disease control relies on getting the correct dose of active ingredient to its target. CPM finds out how the adjuvant Kantor can help fungicide delivery and maximise its performance in the leaf.

Large molecules, like prothioconazole, can need extra help to get inside the plant.

By Lucy de la Pasture

There’s no getting away from the fact that it’s a challenging time in agronomy. Some disease pathogens are evolving at a much faster pace than the chemistry used to control them.

It’s a situation made harder as the regulatory bar is set ever-higher, limiting the pool of active ingredients available to draw on. That means getting the most out of the available fungicides has never been more important, says Agrii regional technical adviser and Cambs grower David Felce.

Some pesticides begin to break down as soon as they are combined with alkaline water in the tank.

Although SDHI/azole mixtures are still giving good field control of septoria, monitoring data shows there’s been a further shift in the sensitivity of septoria to SDHI and azole chemistry. But there are things we can do to optimise spray delivery and help counter this move towards resistance by getting the intended amount of active ingredient to its target site, he points out.

“Optimising the delivery process is in grower and advisor control. Adjuvants can be a valuable tool to help achieve this and we’re expanding the adjuvant trials in 2019 to take the evidence we’ve collected over the past decade to another level,” he says.

One of the adjuvants Agrii identify as promising is Kantor, which claims the ability to influence every stage of the delivery process from sprayer tank to uptake in the leaf. David admits his technical integrity makes him immediately suspicious of a product that promises to be all things to all people.

So he’s been putting Kantor through its paces, and trying to understand which of its many properties is useful in any given situation, a process reflecting the learning curve most agronomists are on when it comes to finding out which is the right adjuvant to use in the right place, he believes.

A primary factor which can influence the effectiveness of pesticides is the quality of the water used in the spray mix, he explains.

“One of the most important is the hardness of the water – the presence of calcium and magnesium ions – which reduces the effectiveness of a number of active ingredients. Other products are affected by the pH of the water. The more alkaline the water, the more rapidly the pesticide breaks down, reducing absorption into the leaf,” he says.

“Alkaline hydrolysis can be very fast when the pH of the water is greater than 8 or 9. Some pesticides begin to break down as soon as they are combined with alkaline water in the tank and as a result, the active ingredients start to change to inactive ingredients before the pesticide even leaves the spray tank,” adds Interagro technical manager, Stuart Sutherland.

The evenness of spray application hinges around droplet size uniformity.

“Reduced product performance may not be obvious. In some cases, the influence of water on the pesticide reduces its effectiveness only slightly, yet enough that tolerant or tough-to-control weeds, insects, and diseases are not well controlled. So time spent addressing the quality of water used in the spray tank can pay big dividends.

“By adding Kantor to the spray water first, it acts as a pH buffer and maintains the water at pH6, which is ideal for most crop protection products,” he comments.

One of the most important actives in the battle against ramularia and septoria is chlorothalonil, which is only stable below pH7. Pyrethroids are also very susceptible to alkaline hydrolysis, decreasing their efficacy.

David highlights that in areas where water pH is high, it’s important to vary the rate of adjuvant to the water volume to achieve the required buffering effect.

The next useful property of Kantor is the effect it has on droplet size, he explains. “Kantor reduces the number of droplets at either end of the spectrum, producing a more uniform droplet size which makes the spray more predictable and less prone to drift.

“The evenness of spray application hinges around droplet size uniformity and Kantor appears to have the ability to increase VMD (volume mean diameter) and we’ve seen this effect where we’ve looked at droplet distribution using water sensitive paper in the field,” he says.

In 2018 Interagro commissioned a study with Silsoe Spray Applications Unit to quantify the reduction in spray drift by adding Kantor (at 0.15% v/v) to widely used fungicide Kestrel (prothioconazole+ tebuconazole), explains Stuart.

“Tests were conducted using a typical Lurmark 03F110 flat fan nozzle at a water volume of 200 l/ha. Measurements were made of droplet size distribution using laser diffraction and Kantor reduced the spray volume with droplets less than 100 microns by 23% (statistically significant). By reducing drift and also improving deposition, Kantor leads to an improvement in coverage.” he adds.

David stresses the importance of spray coverage, especially when it comes to fungicide applications. “Multisites act as a protectant but don’t move on the leaf so they can only protect the leaf they cover. Azoles and SDHIs have acropetal movement, so will move from where they land towards the end of the leaf. So if the base of the leaf doesn’t receive adequate coverage the fungicide will not move in a downwards direction and that part of the leaf will either be completely unprotected or have received a sub-lethal dose of active ingredient.”

Resistance management is all about matching the dose of active ingredients to the disease pressure without exerting undue selection pressure on the pathogen population. So disease control has become even more about getting the right amount of active ingredient onto the target, he adds.

And for David, the most desirable of Kantor’s properties is the way it helps get the active ingredient to the target – by retaining the active ingredient on the leaf, spreading the spray droplets and helping the active penetrate the waxy cuticle of the leaf. Stuart explains how Kantor achieves these many functions.

“The surface characteristics of the leaf influence both the retention and spreading of the spray solution on the leaf surface. Typical water retention in barley is less than 5% and in oilseed rape, 20-40%.

“Small weeds, hairy leaves and wheat ears can be difficult targets. When a spray droplet lands on a leaf it may be retained or bounce/run off. Aqueous fungicides have droplets with a high dynamic surface tension, which will frequently bounce off leaving the leaf or ear with poor coverage.

“Kantor reduces the dynamic surface tension of the spray droplets, allowing them to spread out on impact and increase the area of contact with the plant surface. This reduces the propensity for spray droplets to bounce or run off,” he explains.

One of the most effective ways to improve efficacy is by increasing the penetration of the active ingredient into target leaves.

“The leaf cuticle is the most challenging barrier for the penetration of pesticides, particularly at low temperatures. Kantor, due to its extremely small molecular size (three times smaller than most adjuvants) is able to ‘concentrate’ the number of molecules on the leaf surface,” explains Stuart.

“The entry into the leaf is determined by a diffusion co-efficient, where the higher the concentration the higher the entry. Kantor increases the lateral diffusion of the active across the cell membrane into the leaf by increasing contact with the leaf and increasing the number of entry points into the leaf.

So what does this mean in practice? David explains that these are properties that are particularly useful with some fungicides.

“Kantor acts as a good penetrant and this is beneficial because we apply fungicides to the outside of a waxy leaf and the disease is growing inside the leaf, so azoles and SDHIs need to get through the cuticle of the leaf to reach their target.

“Large molecules, like prothioconazole, can need extra help to get inside the plant. The faster it penetrates the better because it needs to be metabolically activated to desthioconazole within the leaf.”

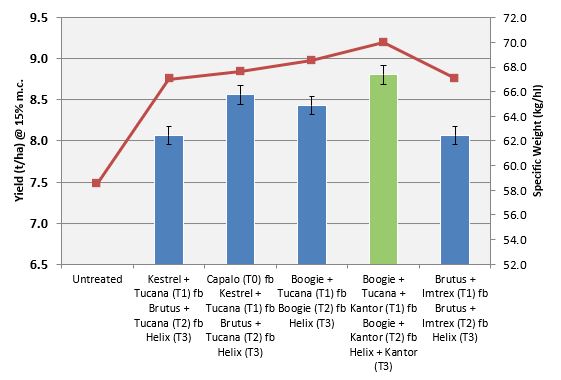

In Agrii trials, use of Kantor with a three-spray fungicide programme has given a statistically significant yield increase of 0.36t/ha, worth approx. £40/ha, over the same treatment programme without the adjuvant.

In this trial Kantor with a T1 application of Boogie Xpro (bixafen+ prothioconazole+ spiroxamine) plus Tucana (pyraclostrobin); a T2 application of Boogie followed by Helix (prothioconazole+ spiroxamine) at T3.

Prising apart the contribution to extra yield at the different timings is complex but David rates Kantor as being particularly useful in situations where there’s antagonism with chlorothalonil. It’s a known problem with SDHI chemistry, with uptake of bixafen being particularly affected by a coating of chlorothalonil on the leaf.

“Some coformulations containing chlorothalonil show less antagonism with fungicides. An example is Pentangle (chlorothalonil+ tebuconazole) where the addition of the azole seems to make the formulation less ‘sticky’. Kantor has a similar effect, so helps avoid antagonism as well as improving spray coverage and uptake when it’s added to the mix,” he comments.

Fungicide trials with and without Kantor

Results are averaged across variety and seed treatment.

P (Yield) = <0.001, LSD (Yield) = 0.221, cv (Yield) = 5.5%, P (SW) = <0.001, LSD (SW) = 0.94, cv (SW) = 2.6%

Source: Agrii trials

David believes there’s likely to be more benefit from adding Kantor at some spray timings, or situations, than at others. “At T0, if the spray water’s cold and there are several components to the tank-mix, then Kantor can aid compatibility by helping keep all the products fully dispersed in the water phase.”

He also suggests that if stem-based disease such as eyespot is the target then a silicon-based adjuvant would be the best choice to get spray droplets to run down the stem.

At T1, he reckons there may be an argument for adding Kantor if curative activity is required, but if a T0 was applied in good conditions and well-timed, then he sees less justification for it. But there’s a definite benefit from using Kantor at the T2 timing, adds David.

Although the theory stacks up at T3 and the addition of Kantor should improve coverage of a difficult target, David believes it’s less clear cut because the success of treatment is highly dependent on timing as well as coverage.

“The T3 spray is a protectant, so it needs to cover all sides of the ear. Although I’ve seen fusarium infection held in trials treated with fungicide plus Kantor, I believe we need to do more work on adjuvant/nozzle combinations to be more definitive on the benefits,” he explains.

Although getting the most out of fungicides is a key area of interest at the moment, Kantor can be a useful addition to the tank in a number of other situations, says David.

“The PGR Moddus (trinexapac-ethyl) is metabolically activated within the plant so needs to get into the leaf to be effective.

“We’ve also found the phytotoxic effects of some spring herbicides have been reduced when Kantor is added to the tank. Notably, Basagran (bentazone), which can be a ‘hot’ herbicide, has been a lot kinder to the bean crop when applied with Kantor, and with improved weed kill,” he comments.

Use with sulphonyl-urea herbicides is another area where Agrii have seen benefits. Trials with Harmony M (metsulfuron-methyl+ thifensulfuron- methyl) have shown an improved level of control of broadleaf weeds, including ivy-leaved speedwell and knotgrass, where Kantor has been added to the tank.

“SU herbicides are very under-wetted because their low rate of active ingredient makes it physically difficult to add in enough wetter when it’s formulated.”

Summing up his thoughts, David says there’s a lot of potential in using the right adjuvant in the right situation to improve pesticide efficiency and Kantor may prove a valuable resource to give fungicides support in some situations.

Pushing performance

At the heart of good crop production lies careful use of chemistry to protect the plant and maintain performance, right through the season. But optimising the efficacy of plant protection products can be challenging, while increasingly restrictive regulations limit just how far you can go.

This series of articles explores the science behind the use of adjuvant and biostimulant tools to help power both chemistry and crop performance, as well as increase understanding of why they’re needed and what they do. We’re setting out to empower growers and drive crops to reach their full potential.

CPM would like to thank Interagro for kindly sponsoring this article, and for providing privileged access to staff and material used to help put the article together.

Kantor is a unique adjuvant designed to optimise every stage of the spray delivery process to help enhance the performance of crops protection inputs and maximise yield in a wide range of crops.