Kent grower Andrew Howard has been pioneering ways in which pulse crops can be grown together with other spring breaks to shore up returns. CPM visits to find how research through the farmer-led network could significantly boost benefits.

Mother Nature never has a monoculture, and there’s a reason for that.

By Tom Allen-Stevens

As the spit of soil splits open on the fork, no fewer than three worms are caught like pink ribbons across the freshly cleaved surfaces, and retreat quickly into their interrupted burrows.

“I counted 60 worms in a spadeful I dug up last year,” remarks Kent grower Andrew Howard, who’s poised to plant not one spring break crop, but two, in the same pass, into this field of alluvial loam that edges the River Stour near Ashford.

“Everything we do is about improving the soil and geared towards creating a healthy environment around the seed, and that’s allowed us to reduce our inputs,” he says.

Each horizontal slot created on either side of the disc can be set at different depths, allowing two seed types to be planted in the same pass.

Since 2001, the plough hasn’t touched the 300ha of arable land, farmed by Andrew and his father Peter, based at Oaklands Farm. Following ten years in a min-till and then strip-till regime, the business, Bockhanger Farms, bought it first direct drill in 2011.

But it’s not so much the cultivations as the cropping that’s of interest here. Alongside the winter wheat, herbage seed and winter beans in the rotation is a spring-cropping approach that sees two or even three crops grown together as companion crops – drilled the same day and harvested together.

“Cover crops always do better in a mixture – you get a better growth than you would if they were drilled by themselves – so the same diversity should work for cash crops,” Andrew reasons. “Mother Nature never has a monoculture, and there’s a reason for that.”

It’s a sound principle from regenerative agriculture, but Andrew resists being labelled. “I’m neither an organic nor fully conventional farmer – I guess you’d call me a hybrid. But the reason we’re companion cropping is to add value. Spring break crops are so variable, so by planting two crops that complement each other you spread the risk.”

His first foray into the technique was about six years ago. Inspired by the conservation agriculturalist Frédéric Thomas, he established a 24m strip of his winter OSR with a companion crop of berseem clover and vetch. These were then sprayed out with Galera (clopyralid+ picloram) in the spring. “It worked well, so within two years we were establishing all our OSR with a companion crop, mixing the seed in the same hopper.”

The crop didn’t need a pre-emergence herbicide, there was less pigeon damage and he could reduce N inputs. He also found the companion plants helped the OSR put down its roots. But a build-up of verticillium wilt, unrelated to the companion plants, put a cap on OSR yields, and the farm has since moved away from the crop.

“We were already growing beans so looked towards other break crops. The problem with peas has always been keeping them off the ground. But I’d heard about peola, which is intercropping peas with spring OSR, or canola as it’s known in North America. The OSR acts as a trellis for the pea crop.”

Unlike the previous companion crop, in this case both crops are taken to harvest, potentially raising total yield. Intrigued to find out more, Andrew applied for a Nuffield Farming Scholarship, and thanks to funding from AHDB, set off in 2015 on travels to farmers around the world. This included France, USA and Canada, Germany, Switzerland, Kenya, South Africa, Sweden and Denmark.

The potential rewards are there, he found. Total yield increases of 20-30% are easily achieved by farmers in a climate similar to the UK. “What really surprised me are the different crops and combinations farmers are trying. But there’s no blueprint – you have to experiment to see what works for you.”

What also surprised him was the amount of research that had been carried out, that hadn’t made its way onto farms. “There’s actually a lot of literature on intercropping, much of it carried out here in the UK. But it’s all sitting on a shelf – what’s needed is more on-farm research. There’s a fair bit of intercropping in organic agriculture, but precious little done by conventional farmers.”

So if the benefits are there, why isn’t there more intercropping in the UK? “I believe the research needs to be funded and carried out by farmers, levy boards and governments. We cannot rely on agrochemical companies to fund and develop research in this field as there’s little opportunity for patents or profits.

“We also need to develop specific machinery for certain intercropping systems for them to be successful. This is needed at all stages of growing intercrops from seeding, weeding, through to harvest and separation. Modern engineering can solve any machinery issues found in intercropping – it just needs funding,” he adds.

His own system involved a John Deere 750A drill, but this year all crops will be established with a 3m Cross Slot drill, purchased in 2018. His 2017 crop, established on 4 April, was drilled following a cover crop of oats, vetch, linseed, phacelia, buckwheat and sunflowers, grazed off and then sprayed with glyphosate.

“We drilled the OSR seed first at 12mm depth, then the peas at a 30° angle and 50mm depth – both need warm soil to help them get going. I think doing it that way round helps press in the OSR seed, but you can set the Cross Slot to drill each seed type at different depths in just one pass.”

The crop was rolled afterwards and received pre-em Centium (clomazone). Biscaya (thiacloprid) was applied in early June for pollen beetle, but Andrew reckons the companion crops come under much less pest pressure than monocultures and plans to grow them without insecticide in future.

He does spend on trace elements and biological treatments, however. “It’s about creating a healthy environment around the seed to encourage rooting and N fixation. So we applied diatomaceous earth, Phos-Life, seaweed and Bioplus T with the seed. It worked out relatively expensive in 2017, but I think we can cut this to half rate and still get the same benefits.”

More biostimulants and biological treatments were applied with the early June application of trace elements following a leaf-tissue test, including Bacillus spp of bacteria believed to have growth promotion and disease-control properties. No fungicides were applied, however.

“I’m fed up with input costs going up and not bringing a yield benefit,” says Andrew. “Most farms don’t get massive yields, and it’s simply not sustainable – excess N application to crops is the worst thing we do in terms of driving weeds, disease and crop growth problems.

“I prefer to feed the biology around the plant, to help it build its own resilience and take up what it needs, rather than put it under stress. Nutrients it can’t access are best applied through the leaf, in my view.”

Harvest management is where crop planning pays off. “There are two essential rules with intercropping – choose crops that ripen at the same time and that you can separate. I found you can’t separate oats and linseed very easily, for example.”

A week of catchy weather at harvest time helped bring the crops together, and combining, with the pea sieve installed and wind speed turned down, progressed without a hitch. “The sample was surprisingly clean, but the main thing was the crop was standing beautifully.”

The crop was passed through a second-hand cleaning plant the business has purchased and installed, yielding just under 3.5t/ha for the peas and 0.4t/ha for OSR. “I was slightly disappointed with the pea yield, so it was a success, but not a massive success,” he notes. “There are a number of things we’re going to vary this year.”

Firstly, the pea variety grown will be different – the large blue crop in 2017, although it brought a good result, was not the most lucrative, so a marrowfat variety, on contract to Gleadells will be grown for 2019.

The farm is also running a peola trial with Innovative Farmers. This is a network for farmers and growers who are running on-farm trials on their own terms. It was launched in 2015, on the back of the notion that many of the best ideas in farming come from farmers themselves. But instead of going it alone, with learning staying on the farm, it’s done in groups, with findings shared and a researcher assigned to each project to ensure sound experimental design and that knowledge and related R&D is truly put into practice.

Although initiated by The Soil Association, any farmer can join the network and suggest a ‘field lab’ – the term coined for the on-farm trials, with the aim being that they are set up quickly and seen as practical. The group decides on the topic and the researcher helps design a trial, which is funded by one of a growing number of sponsors and partner organisations. Currently there are 50 field labs underway that can be on any issue that makes farm businesses more sustainable and resilient.

There are 25 farmers in the intercropping in arable systems group, with the Organic Research Centre (ORC) providing the research support. Andrew’s peola field lab comprises four strips of up to 0.8ha, replicated, testing monoculture peas and different SOSR seed rates. “In 2017, we reduced the pea seed rate to 80% and added 70% of a standard OSR rate, but this time we’re going to keep the pea rate at 100% throughout. The OSR will be sown at half rate and a third rate with one trial including 70 seeds/m² of oats as a nurse crop.”

This follows experience last year with a crop of linseed. “We had real problems with flax flea beetle but there was a patch of wild oats and the linseed within this was hardly affected. In the peola trial we want to see if a nurse crop of tame oats will help against cabbage stem flea beetle in the same way.”

Despite notable successes, the intercropping hasn’t been completely successful, Andrew admits. “We drilled 30ha of spring beans last year with OSR, but the OSR failed to establish in one of the fields. I’m not sure whether it was slugs or CSFB, although the bean crop still yielded 3.6t/ha.”

But the approach does work with spring beans, he notes. “Two years ago we tried beans with spring oats. We were worried that the oats could compete too much with the beans, but that wasn’t the case – we achieved a 15% increase in total yield, including 0.7t/ha of oats. I reckon there’s scope to raise the seed rate higher, so this crop’s going to form the basis of a second on-farm field trial we’re running this year.”

This one’s part-funded and administered by PGRO (see box on pxx). Five replicated large-scale plots will compare monocultures of each crop with intercrops sown at different rates. “We’ll have a 25% seed rate of oats in a full stand of beans and also a 50:50 mix of each. Finally, we’ll see the effect of lowering the bean seed rate and doubling the oats,” he explains.

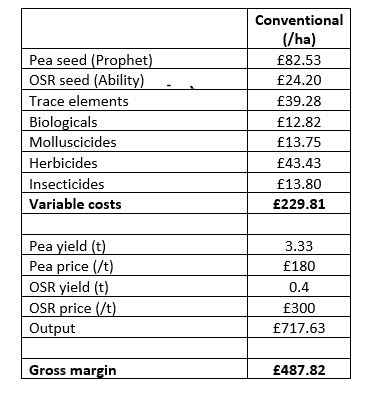

The new cropping culture sits very neatly within the regenerative agriculture route that Andrew’s keen to pursue. But there are also hard-nosed business benefits, he stresses. “We’re reducing both reliance on inputs and risk. While the return from many spring break crops is notoriously poor, through intercropping we are trying to achieve good consistent returns.” (see table on pxx)

He’s planning to use his experience in a consultancy role to help others get started in no-till, cover crops and intercropping. “We’re learning all the time and sharing ideas. I’m convinced the farmer-led network is the right route to explore the benefits of this approach. Through these on-farm trials and close involvement with the research community we’re at last pulling some valuable R&D off the dusty shelves of research institutes, into fields and into the hands of farmers where it belongs.”

Farmers sought to quicken the pulse on intercropping

PGRO has been carrying out its own fully replicated small-plot trials into intercropping and is now looking for farmers to get involved in larger tramline trials, reports principal technical officer Stephen Belcher.

“The reasoning behind it is that you may produce a lower yield of each crop, but more in total, which makes for greater land use efficiency. There are also other benefits, such as ease of harvest for some crops or less disease or pest pressure.”

Small-plot work at PGRO’s site in Stubton, Lincs, is currently looking at peas and oats, peas and beans and beans and oats. “The advantage of peas and beans is that similar crop protection products are approved for use in these crops, which can be a limitation when mixing pulses and cereals. But they are harder to separate at harvest,” he notes.

PGRO is part-funding the beans and oats trial at Bockhanger Farms. “The trial is very much led by Andrew, and we’re providing some funding to help ensure there’s some scientific rigour,” explains Stephen.

“We’re very keen to do more of these farm-scale trials as they can provide very useful pointers, particularly with practices such as intercropping. Ideally the ideas should come from the farmers themselves and we’d look to them to provide most of the management, but would provide some funding and scientific input.”

- There’s more from Stephen on intercropping in the current Pulse Magazine included with this issue of CPM.

Bockhanger Farms peola: how the finances stack up