Developing a new manganese-containing product could be described as re-inventing the wheel, but Levity Crop Science has used its unique scientific perspective to not only redesign the wheel but to improve it. CPM investigates

It’s not all about the amount of manganese that’s applied.

By Lucy de la Pasture

At first sight there’s nothing particularly revolutionary about a product which supplies manganese to cereal crops. It’s been common practice for years to apply manganese salts and chelates to supplement crops during periods of rapid growth.

So when Levity Crop Science’s founder David Marks was asked to develop a product to deliver manganese to the crop, he didn’t want to simply reinvent the wheel. Instead he went back to the drawing board and using his background in science and agronomy, came up with a more complete solution to the problem manganese applications are often trying to address.

Levity has used its know-how to develop a product which improves the photosynthetic capability of cereals, says David Marks“Traditionally manganese is applied as heavy suspension concentrates but the trouble is that it’s not actually in a form that’s very available to the plant. There had to be a better way to deliver it,” he comments.

“Manganese applied in a heavy suspension form has the effect of greening-up the crop for a few days but in trials we’ve found that there wasn’t a prolonged effect.”

Looking more closely at why manganese was being applied, David also asked the question why so much was needed and what was it trying to achieve?

He found that although manganese is not very available in some soils, applications were often being made when the crop goes yellow in the spring as it helps return it to a healthy-looking green.

“Plant roots ‘wake up’ more slowly in the spring than the top growth which is why some crops go through a transient yellowing,” he explains.

David has a strong history in the research of nutrient use efficiency and he passionately believes too much fertiliser is applied and wasted. He works on the principle that by understanding how plants take up and metabolise the nutrients they use, it’s possible to develop products that target the parts of the crop that are actually deficient, support the physiology of the plant to produce more yield and can be used at lower doses.

So what’s the role of manganese in the plant? Manganese has an essential role in the manufacture of chlorophyll – the pigment responsible for harvesting the light in photosynthesis – which is one of the reasons why when plants don’t get enough, they go pale green.

From this, David deduced that the reason for applying manganese is to maintain the photosynthetic capability of crops, so he set out to develop a product that would do more than temporarily balance the crop’s demand for manganese.

“As well as support the crop’s physiology in times of need, we wanted to help the crop to develop the right structure to both capture light and use nitrogen more efficiently so that it can place more energy into harvesting the light through photosynthesis,” he explains.

So from looking at things from the perspective of the plant’s physiology, the concept of the Elona range of products was born – a name which means ‘light’.

Manganese is far from the only nutrient that has an important role in photosynthesis. Another key nutrient is nitrogen because it’s a major component of chlorophyll – the compound by which plants use sunlight energy to produce sugars from water and carbon dioxide (photosynthesis).

“It’s also more normal to talk about the amount of nitrogen applied than the form in which it’s supplied. In reality, the plant only uses a fraction of the nitrogen applied as nitrate and ammonium, so it’s a wasted resource,” believes David.

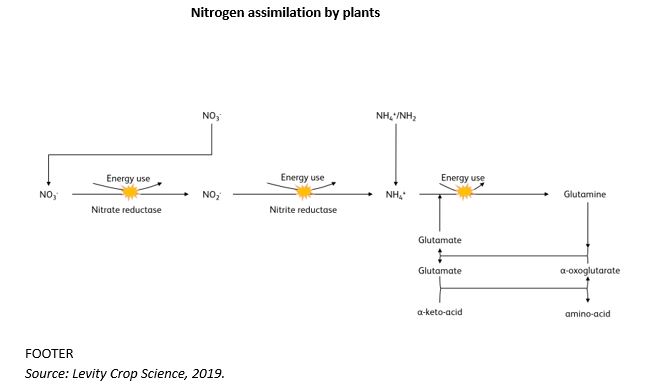

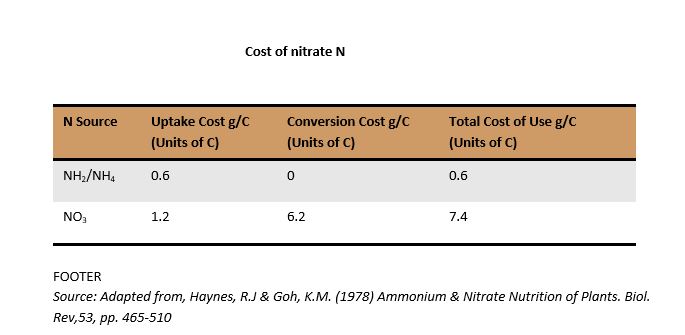

Why is nitrogen form so important? The nitrogen taken up by plants as nitrate (NO3–) must be converted to ammonium (NH4+) before it can be used, he explains, and this process has an energy cost.

“NH4 and amine (NH2) may be used immediately in the synthesis of amino acids and other organic compounds, conserving energy which can be used for growth,” he says.

Until about a decade ago there was no known mechanism for uptake of amine (NH2) by plants, but it’s since been discovered that there is a direct mechanism for plants to take up urea as a whole molecule, explains David.

It was a game changer in realising the potential of using different nitrogen forms as fertilisers.

“Plants do take up organic nitrogen, which is by far the biggest pool of nitrogen available to them. They can compete with bacteria for theses organic forms and don’t just process what the bacteria have left.”

“The different forms of N also have a significantly different effect on plant physiology and can be used to influence where the plant drives growth. Most of the commonly applied N-fertilisers encourage vegetative growth, which can make plants weak and more susceptible to pests and diseases. In practice, growers usually have to apply plant growth regulators to counter the effects of applied nitrogen to stop plants from getting too leggy,” explains David.

One of the functions of nitrogen in the plant is to influence the production of plant hormones, particularly auxins and cytokinins which are the hormones influencing plant growth. The nitrate form stimulates plants to produce auxins, which is why overapplication causes excessive top growth. If the plant has access to nitrogen in the form of NH2 then it can use this locally, using less energy to convert it to protein and without triggering unwanted auxin synthesis. The added bonus is that amine boosts cytokinin production, resulting in robust shoots and better rooting.

So the scientists at Levity combined their stabilised-urea technology, LimiN, which prevents the amine from changing to other forms before the plant can use it, with a further technology developed in-house which aids the uptake of nutrients, known as Catalyst.

David also looked at the other nutrients that play an important role in photosynthesis in cereal crops and in addition to manganese, the Limi-N is also powered with magnesium (one of the building blocks of chlorophyll), zinc and copper (both involved in many metabolic pathways).

The Catalyst technology was first developed to assist the uptake of a range of nutrients, explains David. “In trials it’s been shown to also improve key physiological indicators, including chlorophyll fluorescence and stomatal conductance,” he explains.

And it’s those properties that make it a perfect ingredient to complement the action of the Limi-N and micronutrients in improving photosynthesis and also helps to accelerate nutrient uptake by the plant.

“The addition of Catalyst, with the benefit of supplying N in the right form (attached to the Mn and Mg), makes for a product that improves nutrient uptake, improves the plants ability to use the nutrient and makes a better growth habit – one which has an improved architecture for light harvesting and better roots to help the plant help itself,” he comments.

The combination of Elona’s formulation technologies means that plants have an increased ability to harvest light over a prolonged period of time and not just provide a temporary greening effect.

“We’ve considered how everything works together and we’ve found that it’s not all about the amount of manganese that’s applied. With Elona, a lower g/l of manganese has a better effect on the crop than a heavy loading, as is used in the traditionally-applied heavy suspension products,” he explains.

Elona was put through its paces in trials at Myerscough College, Lancs, in 2018. When assessed alongside a control and industry-standard treatment, Elona treatment gave significantly different improvements in tiller development and survival. It also significantly increased the content of chlorophyll in the leaf and this was found to be a sustained improvement.

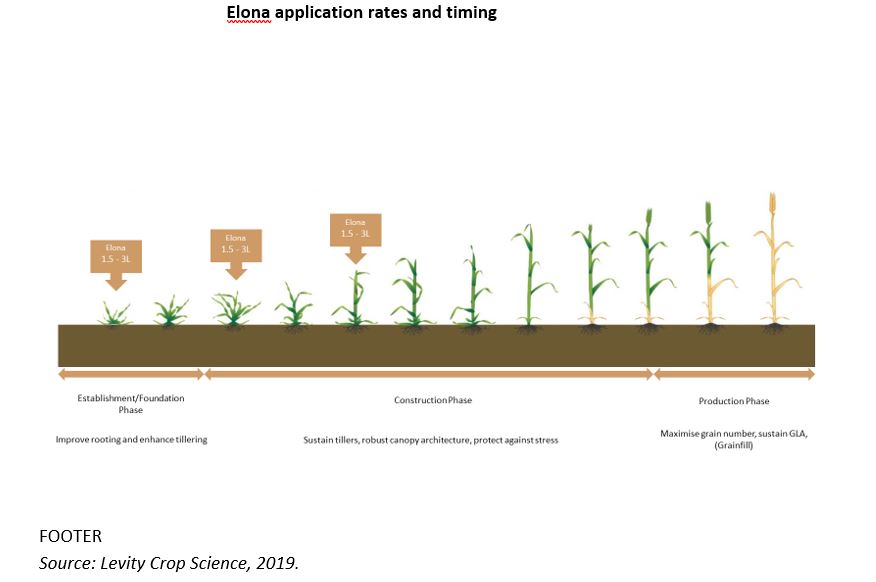

In cereals, yield is dependent on the number of ears/m2 so enhanced tillering and the ability to sustain tiller growth are important factors in constructing the yield potential of crops. Levity has found that during tillering and at the start of stem extension the best timings to apply Elona, with 2-3 treatments the norm depending on the crop and soil type. Further treatment may be advisable if the crop comes under osmotic stress, adds David.

Innovation timeline

LimiN

- 2011 – started work on in 2011

- 2015 – launch of Lono for potatoes in the Netherlands

- 2016 – expanded the crops and markets

- 2019 – research ongoing

Catalyst

- 2010 – development began

- 2013 – proof of concept in the lab

- 2016 – launch of first commercial products containing technology

Elona

- 2016 – development began, incorporated Limi-N and Catalyst technology

- 2018 – first use in the field

- 2019 – UK launch

Elona looks promising in the field

Adam North, agronomist for Pearce Seeds, used Elona when a small quantity became available for use in 2018, in advance of its official launch this year. Once he’d heard David talk about the technology behind the product, he realised this was a product with proper scientific credentials.

“So many products in this area are branded as muck and mystery. It is true that some have been mis-sold and make claims they can’t support. But the depth of David’s knowledge is fascinating and he’s someone who thinks very differently,” says Adam.

David hesitates to describe Elona as having biostimulant properties because he doesn’t want it to be lumped into the same category as the many products emerging in this fast-growing field. He prefers the term ‘enhanced nutrition’.

But Adam has seen the effect of Elona himself on crops struggling in very dry conditions so says it definitely has a beneficial effect on crops under stress. He’s even noticed a crop-safening effect when used with some herbicides.

“Where Elona is applied, I’ve seen plants are ‘tighter’ and more robust – in field you can see where you’ve applied it to the line,” he says.

Adam advises in Somerset, where soil types vary from low-lying heavy clay to high pH brash soils overlying limestone. “In general the soils I work with have a pH of 6.5-8.5 which makes manganese less available and the heavier land that can lie wet in the winter, so a lot of manganese is applied to crops,” he says.

Having worked as a spray operator in the past, he’s very aware of some of the practical difficulties that are encountered using some manganese formulations.

“Some manganese forms are not very friendly to the spray operator. Carbonates and heavy suspensions tend to settle out in the can, which means they can be very difficult to empty. Elona comes out of the can like any normal fungicide and tank-mixes with ease,” he says.

In recent years Adam has favoured manganese nitrate/sulphate formulations which have been considered the most easily available to the crop. But having used Elona, he describes the formulation as being ‘light years ahead’.

“The stabilised amine form of nitrogen used in Elona has superior effects to the crop and will stay put if it lands on the soil. If it comes in contact with a root then it will also be taken up. There’s wide scope to use Elona in the autumn to improve rooting and enhance tiller survival which is something I’ll be aiming to do more of,” he comments.

Asked how Elona compares in terms of cost? “It’s equivalent to an application of a manganese nitrate product but brings more to the party for the same amount of money,” notes Adam.

Innovation Insight

CPM would like to thank Levity Crop Science for kindly sponsoring this article, and for providing privileged access to staff and material used to help put the article together.