Beeswax Dyson Farming has achieved impressive results from the scientific probity applied to the arable land in its care, but how does that translate into carbon cost? CPM gets an exclusive insight.

It’s not about the destination, it’s about the journey to get there.

By Tom Allen-Stevens

On the way to one of the farm’s two AD plants, you pass a field of potatoes with wildflower strips not just around the headland, but in the tramlines, too.

“It makes sense not to crop areas of the field where production is always compromised,” notes managing director of Beeswax Dyson Farming Richard Williamson. “Putting in wildflower strips increases the population of beneficial insects which reduces our reliance on pesticides and results in a more sustainable, and ultimately more profitable crop.”

Wildflower strips planted not just on the headland of potato fields but in the tramlines, encourage beneficial insects and reduce dependence on pesticides.

It’s a simple idea, and a logic you’d be hard pushed to find holes in. And if you tried, you’d probably find there’s data aplenty to back up the practice. That’s because everything you see, hear and experience about this business, now the largest farming concern in the UK, tells you that everything is done with a true sense of purpose.

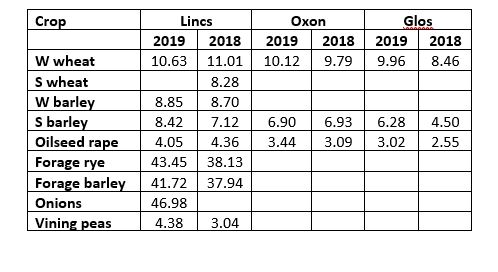

“We want to be a force for good in agriculture,” says Richard. “That means being good custodians of the land, long-term landowners and good neighbours.” Centred at the Nocton Estate in Lincs, where the company now farms 11,300ha (farmed as two units across a 70-mile radius), there’s another 4000ha reaching across Oxon, Glos and into Somerset. Two thirds of the turnover come from farming – most crops, other than fruit and vegetables, are grown plus beef and lamb – 28% from the AD plants and the rest from its property portfolio.

It’s a business that benefits from generous investment – that’s clear from the miles of drains recently installed or replaced; from the water main currently going in to serve the new reservoir that will keep crops irrigated as water becomes ever scarcer; from the new generator being installed at the AD plant that puts the entire estate effectively off-grid.

But Beeswax is operationally profitable – in fact the latest accounts show that in just five years, it’s turned around a £4.5M loss to a £2.6M profit. “We want to be less reliant on EU subsidy, and that’s been a fundamental aim. We want to be sustainable in a rounded sense, both economically and socially,” notes Richard.

You yearn to learn what lies behind this turnaround of fortune, and it could be the dedication to detail of the farming system itself. This is evident from the farmyard, for example, where nothing’s out of place. Well, it’s not so much a yard as a set of modern buildings Richard calls “fit for the future”, one of three across the business that store 22,000t of cereals and oilseeds and 8000t of potatoes.

“Everything is processed digitally,” explains Richard. “We don’t use any paper forms and can track every kg of produce, what’s used to grow it and transport it from the field to the store to its final destination – we even have our own system of electronic grain passports.”

Step forward and nominate yourself as a CPM Climate Change Champion.

But the fundamental change Beeswax has introduced is in the way it manages the land, he insists. “A lot of arable land is degraded, but it’s not suffered permanent damage. So what we’ve set about doing is putting the soil back into good working order.”

It started with the drainage. “It’s been a bit of a carry-on at times as we’ve installed drains, and we’ve wondered whether some fields would ever be productive. But we’ve analysed performance closely – there have been fields that previously couldn’t be cropped three years out of ten, and were choked with grassweeds, and we’ve been buoyed up by how quickly we’ve turned them around.”

Hand-in-hand has been a focus on blackgrass. The business inherited a heavy burden across much of the generally good quality soils it acquired. These range from light Lincs Heath limestone to heavy clay, with plenty of areas of silt, fen and marsh across the arable area.

Head of farming James Thompson has taken a systematic approach to dealing with blackgrass. “We run a risk-scoring matrix across all fields. So the worst ones are category three, where levels are extreme and there’s no winter cropping,” he explains.

“Category two is manageable within the rotation, while one is clean of blackgrass, or as near as. We have a suite of about ten different management practices we apply to reduce levels and rigorously apply all ten – I’ve found you need nerves of steel.”

It’s been during the course of putting this land “back into good working order” that James has developed the farm’s approach with cover crops. “I’m a strong believer in the five-minute fallow, so we have no land that lies bare for more than four weeks.”

It was after the drains were restored in one of the first blocks of land to be improved that James determined it needed some winter cover and planted a crop of oats and mustard. “Inspecting the land afterwards – the smell and feel of the soil – the results just felt right, like you were doing some good.”

The farm set about some on-farm trials in conjunction with Boston Seeds to assess the best mixture. Such trials are an integral part of developing practice for Beeswax, notes Richard. “We have around 20 on-farm trials taking place at present. Some of them are our own to assess a specific system we’re interested in. We also work with ag-chem manufacturers and the levy bodies, and we’re one of the 20 ASSIST farms, a public-funded project assessing the best use of uncropped areas to boost pollinators and beneficial insects.”

The cover crop trials spanned 8ha, comparing 30 different seed mixes, recalls James. “You quickly realise the cost of some of the more speciality options, and I’m not brave enough to chance some of the complex ten-way mixes, no matter what results you can achieve.

“Just using any over-winter cover crop brings the biggest step improvement to soil health, we found. We now favour a two to three-way, fairly simple mix that we apply broadly but tweak to the particular soil type or priority of the field in question.”

With the land now in good order, blackgrass under control and profitability improving year on year, Beeswax has started on its most ambitious project to date – assessing and then reducing its net greenhouse gas (GHG) emissions.

“We’re aiming to think ahead as to what people might want of a farm business in the future, and keen to understand what the term ‘public good’ means for us, which is still a very debatable subject,” Richard explains.

“What we need is a matrix we can apply that assesses the fundamentals of air, water and soil quality. We know we’re not going to get paid for looking after our own asset, and currently it’s difficult to quantify what would be better – it’s possible but not easy to measure air or water purity and soil health. But 10% of UK GHG emissions – 20% globally – are attributable to agriculture, and this relates to carbon, a commodity that’s recognisable, measurable and tradable. So there’s potentially a commercial, as well as social reason for assessing where we stand.”

They set about assessing what systems were available, with the help of LEAF (Linking Environment And Farming), and settled on the Cool Farm Tool as the accounting measure to use. This is a tool, available free to farmers, that’s designed to give you a measure of your emissions based on information most arable businesses have easily to hand – just 10-15 minutes work is claimed to give you a rough estimate. You can tailor results, and it highlights hotspots for further investigation.

“The Cool Farm Tool is one that’s used quite widely in the food industry,” says James. “Although it’s free to use, we paid for it and received the training so we could get the best out of it.”

Plugging in the figures was relatively simple, notes Richard, but it was when it came to analysing them that they began to recognise the size of the task in hand. “Cleanliness of data is very important. For most accounting in agriculture, just having the correct figures is enough. For carbon accounting, you need to be able to drill down through the data to interrogate it – successful carbon monitoring rides on having a single source of truth. This throws up the limitations of some of the ways we record our data.”

Richard likens it to reconciling data for your profit and loss account with your crop-recording software. “Unless it’s reconciled, your profit and loss account really doesn’t mean anything. Likewise, with carbon accounting, unless all your data sources marry up, you can’t really get a true picture.

“This may sound trivial, but it’s likely open-source data will become ever more important, especially if we move to situations where carbon accounting becomes auditable.”

Nevertheless, they have built up a general carbon picture of the business. “There are really only four factors that matter,” explains Richard. These are:

- Source of fertiliser, amounts used and how it’s applied

- Cultivation techniques

- Cropping choice (including woodland)

- Livestock and to what extent it’s grass-fed.

“Sorting out just the carbon footprint of your nitrogen fertiliser gets you a long way towards where you want to be,” he notes. For Beeswax, it’s in a pretty good place – a proportion of the N requirement across the arable enterprises is now supplied by 100,000t of digestate liquid and solid generated by the two AD plants. While this supplies all of the N for some of the maize, wheat has around 50% supplied through ammonium nitrate, mainly due to ensuring timing of applications are correct – the logistics of applying digestate can be a limitation here, Richard explains.

For James, the real eye-opener has been cultivations. “The impact of moving soil astounded me,” he says. “It’s not just the carbon cost of the fuel – working that out is easy. The difficult bit is measuring the erosion of organic matter – the moment you move soil you burn carbon. There are some standard figures in the Cool Farm Tool, but if we’re really to draw value from this exercise, we need to know exactly how our systems and soils stack up.”

Beeswax is again already doing pretty well here – all 1000ha of oilseed rape is either strip-tilled, using a Grange low disturbance toolbar and Amazone precision drill, or direct drilled, using a Weaving GD or Horsch Avatar drill. No till is also being rolled out across the cereal acreage, with the Oxon farm now fully direct drilled.

Cover crops also make a palpable difference, but again, although the tool supplies some standard figures, drilling down through them and understanding the impact of a change in practice is harder to gauge, notes James. “Our rotation also comes out well – we have 2000ha of vining peas, which being a pulse crop are low carbon. Areas of woodland also make a significant difference as they sequester carbon.”

So Beeswax knows what it’s carbon footprint is, but Richard’s not sure the actual figure currently has much value in isolation. “It’s a pretty meaningless figure, partly because so few farmers have actually done the exercise. But you can’t really compare yourself with other farmers anyway, because every business will be so different in how it generates GHG emissions. What’s more, the key for a good farming business is to show reductions in carbon emissions, rather than achieve an absolute figure.

“Likewise, I think it’s commendable for the NFU to have a target of Net Zero for the industry, but I don’t think it’s helpful for individual business to set an actual, quantifiable target. It’s not about the destination, it’s about the journey to get there.”

For Beeswax, Richard notes it’s been a very difficult journey to get as far as it has. So will it get the investment back on the time and resource expended so far? “Carbon accounting for farming businesses is at its embryonic stage at present – there really isn’t enough advice and guidance out there. So it has been a hard slog for us and there are still a lot of unanswered questions – we don’t yet have data in which we can have complete confidence. But the steps we’ve taken to date are both positive for emissions and commercial farming practice.

“What’s more, we’ve turned this business round to be far more customer-focused and seek direct supply deals with processors and retailers who are actively interested in carbon accounting. In a post-CAP world, businesses that are closer to their customers, that can be completely transparent about their processes, will be the ones best equipped to connect with a consumer asking ever more searching questions about where their food comes from. Those businesses will be the trusted primary producers for the food industry,” maintains Richard.

Downtime has value in a 24/7 business

At Nocton’s AD plant, that normally runs constantly to supply 2MW of electricity to the farm and the grid, all is quiet. The cylinder heads have been removed from the massive gas-powered engine that drives the generator.

“They’ve corroded and worn out somewhat sooner than we’d like, so the engine is being overhauled,” notes AD plant manager Simon Blades.

Installed five years ago, it was a plant Beeswax took on when it bought the farm. “At the time it was generating just 9000 KWh/day and the quality of the gas was somewhat variable. But it works best at an output of 47,000KWh/day, which is where we’ve been operating it, and there’s a whole science behind making sure there’s a clean, efficient gas it runs on.”

Taking advantage of the downtime, a pasteuriser is also being installed, which will allow a wider range of food by-products to be taken in.

For Simon, the quality of the gas is absolutely key, and this has a direct effect on the efficiency of the plant, both in financial and carbon-accounting terms. “I have to confess, I have a little bit of AD OCD (obsessive compulsive disorder) – I don’t feel I can afford to let things slip,” he says.

“Having said that, the nice thing about working here is that you’re part of a team and everyone is working to the same values. So you can go on holiday, switch off, and everything’s still right when you come back.”

It’s a philosophy Richard underlines. “This is a 24/7, high output business, but it’s so important that the people who work here have the flexibility they need. It doesn’t mean anything has to compromise, though. We always maintain a high standard, but that shouldn’t impact on the staff, who get the time and space to do their job properly. There’s a difference between working hard and being under pressure.”

Beeswax Dyson crop yields (t/ha)