Wondering what herbicide strategy works best on grassweeds? The surest answers may come from on-farm test plots. CPM talks to two growers about their results and gleans expert guidance.

I’ve used all sorts of products over the years, but I don’t really have any idea how much they actually work.

By Tom Allen-Stevens

Over the next few weeks there’s a strong chance you’ll spend a considerable portion of your entire annual herbicide budget on residual chemistry applied to your cereal crop. There’s also a strong chance you’ll have little solid evidence it’s delivering value for money, let alone any idea of the difference between the products available in your particular situation.

It’s this uncertainty that led Warwicks grower David Brightman to conduct his own on-farm test plots. Not only that, he took them to yield and now has some relatively robust data of his own on margin over input cost (MOIC).

“I’ve used all sorts of products against my blackgrass over the years, but I don’t really have any idea how much they actually work,” he comments.

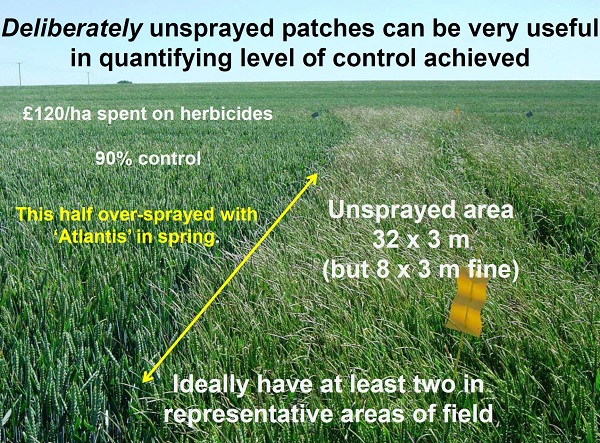

A slide shown as part of a talk given at the Warwicks Farm Management Group prompted David Brightman to consider his own on-farm tests.

It was a talk given by independent blackgrass expert Dr Stephen Moss at the Warwicks Farm Management Group that prompted him to consider conducting his own on-farm tests. “There was a slide of a farmer who’d missed a bit with the sprayer which illustrated the effectiveness of what had been applied. We all go to demonstration days and hear about field trials, but few of us actually do our own.”

Brightman Farms operates across two units of heavy Warwicks clay, farming a total of around 240ha of combinable crops in a six-year rotation. The farm suffers a heavy burden of blackgrass, much of which is now resistant, and was one of the farms involved in the recently completed Blackgrass Resistance Initiative (BGRI). This AHDB and BBSRC-funded research project meant the blackgrass populations in some of his fields were carefully monitored each year of its duration.

“In autumn 2017, I thought I’d try a test plot with a spare bag of Avadex (triallate) in the field the BGRI was monitoring, so asked the contractor to apply it along just one tramline of that field. When the monitoring map came back it was clear there was a difference, although it wasn’t clear exactly how much.”

Last year, he decided to put test plots in two different fields with a similar soil type and blackgrass burden, both cropped to winter wheat after a break crop. “Initially I decided to ask the contractor to switch off half the boom (12m) over a 24m length in each field that I marked out with canes.

“Then I decided to extend the test by switching off the sprayer, so half of each untreated area received no pre-emergence treatment. Then I overlaid test plots of the peri-emergence treatment, by leaving a 36m length of the same 12m width unsprayed and finally marked out plots to show where the three treatments differed from the farm standard,” David explains. The result was two sets of test plots in different fields, each 48m x 12m, comparing four different treatments.

He got in touch with Stephen, who came out to the farm in June and assessed blackgrass head counts. “The best method is to use a quadrat, which is a tenth of 1m², to assess around 20 counts chosen at random in each plot. That gives you a good estimate,” advises Stephen.

“The value with David’s test is that he’d repeated it. These are not replicated trials, but even just a simple repetition can ensure greater confidence in the results. You could also see from the rest of the field he’d chosen an area with a relatively even population.”

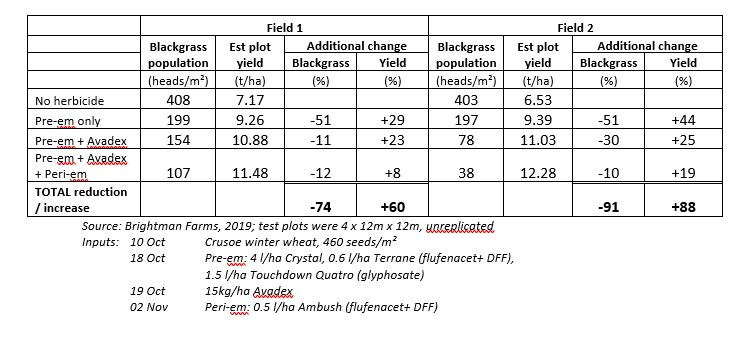

This turned out to be around 400 heads/m² in the untreated area (see table on pxx). “That’s a fairly high population, but by no means untypical. David achieved a total reduction of 74% in one plot and 91% in the other. The interesting aspect is that relative effectiveness of the different treatments were broadly similar over each test area, which raises confidence in the results,” notes Stephen.

The plots were then taken to yield. “I hadn’t intended to do so as it put quite a heavy seed return onto those areas. But there’s yield-mapping on the combines, so I had the opportunity to see if it worked on small plots,” continues David.

This was a lot harder to do than he’d expected. “Precision farming is not as precise as you’d think. We’d been careful to combine the plots in the exact 12m widths, but the data points of the yield map didn’t exactly match up to the plots – you have to do a lot of work to extract the correct data.”

But the results were worth the time spent crunching the figures – again, they were consistent over the two fields, indicating a yield increase of between 60-88%. The degree of the yield differences has opened David’s mind to doing further trials to get a better picture of how to keep his blackgrass in check.

“The two main problems I face are drainage and blackgrass. I may be able to tweak yields by applying a little extra manganese or fungicide. But the biggest difference will always be to get the herbicide strategy right.

“There are practical difficulties with herbicide test plots, however, and they involve a lot of hard work at busy times. Taking them to yield is a real problem, although I now have my own data that relates head counts to the effect on yield. Stephen would like me to keep the areas for the next five years with zero seed return and monitor populations to demonstrate seed decline, but doing that all over the farm may create practical problems.”

Stephen is keen for more growers to carry out their own on-farm trials. “Firstly, assess what your main concern is, and plan how you’re going to test it,” he advises. “Try not to be too ambitious but look at just one or two criteria.” These may be:

- Are you getting value for money on a post-emergence herbicide?

- What difference does stacking extra actives, such as Avadex or prosulfocarb, make?

- What contribution is flufenacet delivering to overall control?

- How does Crystal (flufenacet+ pendimethalin) compare with Liberator (flufenacet+ diflufenican)?

“Repeating test plots over at least two areas increases confidence in the results. Plan ahead so you can chose areas with an even weed density. But the key with herbicides is to repeat tests over successive years, keeping the variables the same – that bit’s always hard, but it will deliver information of most value.”

Taking test plots to yield isn’t necessary for those prepared to accept industry-standard ballpark figures on yield loss, he adds. “That’s around 1t/ha for every 100 blackgrass heads/m². David’s yield losses support this value well.” What growers will glean that can’t be gained from the wealth of data presented by distributors and agchem manufacturers will be information that is truly independent and relates directly to their situation, says Stephen.

“If you take Crystal and Liberator, for example, over 400 trials the results are almost identical. But we do know that control of each varies in different situations. Lab tests and trials have also shown that the efficacy of flufenacet is waning, but it varies depending on the resistance level of the population in question.

“The differences in control you receive with residual chemistry are not always down to resistance, though – organic matter levels, soil type and moisture have a bearing. All these factors vary from farm to farm.”

There’s also a lack of independent research, he notes. “AHDB used to fund this, but there’s very little carried out with herbicides these days. I believe the lack of applied research is a major reason why productivity of UK arable farms is declining relative to those on the Continent. On-farm research could replace that, but it needs proper co-ordination and scientific input. That isn’t expensive, and it’s where AHDB could bring considerable value.”

AHDB funds some on-farm trials on blackgrass through its Farm Excellence Programme, which aims to help farmers look at all the options as part of an integrated approach, points out Dr Paul Gosling. “Work on blackgrass herbicides is tricky because resistance varies from field to field and even within fields. So as Steven suggests, doing their own trials will help farmers understand how different herbicides will work on their blackgrass populations.”

AHDB will be publishing a general guide to conducting on-farm trials in the New Year, which will include guidance on conducting simple trials on weed control.

Brightman Farms test plots, 2019 harvest

Zero seed return ‘not quite achieved’ through 5 for 5

Growers wondering how long they need zero seed return of blackgrass to ensure the weed is no longer an issue may have to keep the pressure up for longer than five years, according to results from an on-farm test.

The 5 for 5 approach for beating blackgrass, developed by Dr Stephen Moss, involves using five strategies for five years, only one of which may be herbicides. Provided there is zero seed return, research suggests growers can achieve a reduction of the population by 99.9%, he says.

But on-farm test plots put in across Andrew Ward’s wheat crop at Glebe Farm, near Leadenham, Lincs, have indicated this may not be long enough. “For the past five years we’ve followed a zero-tolerance strategy with blackgrass and have rigorously ensured no seed has been shed,” says Andrew.

He hasn’t used post-emergence herbicides for four years, relying on pre-ems and roguing. “In May, we spray out with glyphosate areas of crop with a grassweed burden too heavy to rogue, although these are virtually nil now.” This is combined with other strategies from 5 for 5, such as double spring cropping and delayed drilling.

“I wanted to know what contribution the pre-em was making, and whether we may be able to stop using it altogether. We apply glyphosate pre-drilling, then 0.6 l/ha of Liberator, 2 l/ha of Defy (prosulfocarb) and 0.1 l/ha of DFF, then shut the gate. We left single, unsprayed tramlines (32m x 100m) in ten different wheat fields and monitored results.”

While actual plant counts weren’t taken, the plots were visually assessed and categorised according to control strategy in May and June this year. “Three of the plots were completely clean and didn’t need roguing. Two of them we had to spray out with glyphosate. The other five we could rogue.

“While we probably have a lower tolerance for blackgrass than most, this exercise has told me we still need pre-ems across the majority of the wheat area before we can rely on roguing alone to stay blackgrass-free,” concludes Andrew. He plans to repeat the test plots this autumn.