BASF has brought its formulation expertise to the fertiliser industry with a new product to stabilise urea fertilisers and reduce ammonia losses by up to 98%. CPM finds out how Limus works and reviews independent trials results and analysis from this harvest.

Trials consistently show that Limus-treated urea works as reliably as AN.

By Lucy de la Pasture

Earlier this year Defra published a draft Clean Air Strategy for the UK which will likely be brought into legislation sometime during the new session of Parliament. The revised strategy will work hand in hand with the new Agricultural Bill to ensure the UK meets its legal obligations to reduce ammonia emissions.

One of the approaches being considered is making the use of urease inhibitors mandatory when using urea-based fertilisers. In practice, the implication to growers currently using urea will be to either switch completely to ammonium nitrate (AN) fertilisers or to use an inhibited urea product.

The polymer technology used in the Limus formulation means the two active ingredients permeate the urea granules, eliminating losses during spreading.

This season marks the debut of a new urease inhibitor from BASF, Limus, available as both protected granular urea and as a tank-mix additive for UAN. The formulation technology the company brings to the party puts granular urea fertilisers treated with Limus on a level playing field with AN in terms of performance, while also delivering a potential cost benefit, says Richard Corden of BASF Agricultural Solutions.

The aim of treating urea-based fertilisers is to reduce ammonia lost to the air by the process of volatilisation, he explains.

“Urease enzymes are produced by plants, fungi and microbes in the soil and they have an active site that can bind urea. Once bound, urease enzymes begin to convert urea into ammonium. This raises the pH of the soil and ammonia volatilisation can occur if this pH spike is not buffered by sufficient rainfall. Urease inhibitors minimise volatilisation by temporarily delaying this conversion.”

Limus was developed to address some of the challenges originally associated with urease inhibitors. The company has utilised polymer formulation technology to solve the problems of poor stability and short shelf-life long associated with some of the original inhibited urea products.

“Limus is stable for 12 months when tested at 20⁰C, so we believe that under UK conditions, treated urea will have an even longer shelf life,” says Richard.

“BASF’s polymer technology also ensures that the product permeates into the urea granules, which protects them from the losses which can often occur when spreading urease-inhibitor products applied as a coating,” he explains.

Limus contains not just one, but two urease inhibitors – NBPT (75%) and NPPT (25%) – which is another feature that differentiates it from alternative inhibitor products, adds Richard.

“This means Limus is active on a broader range of urease enzymes than products which only contain a single active. Trials work has shown this results in reduction of ammonia emissions by up to 98%.”

Urease inhibitors have a local action, only working around the urea to delay the conversion to ammonium, effectively buying time for the urea to be washed into the soil while safeguarding it from volatilisation – an attribute that’s been valuable during the past two springs which have been unseasonably dry, he points out.

The effect of the urease inhibitors is only temporary so there’s no long-lasting effect to the microbiome in the soil, adds Richard.

“As well as its local activity, the two active ingredients in Limus have a short half-life in the soil. The urease inhibition has effectively gone after 10-14 days,” he explains.

It was the quality credentials of BASF which attracted Bartholomews to independently test Limus in fully randomised, replicated trials during 2019.

The company has a fertiliser importing and blending facility at Southampton docks and has an ethos of rigorously testing products to ensure a sound basis for their advice before recommending them on farm, explains Andrew Stilwell, crop nutrition technical manager at Bartholomews.

The company has been looking extensively at nitrogen fertilisers for the past four years in trials. “The aim of the work has been to determine the best approach to application timings and total N for the most efficient uptake by the crop. It made good sense to include Limus-treated urea in the trial programme to get a measure of how it compared with AN,” he explains.

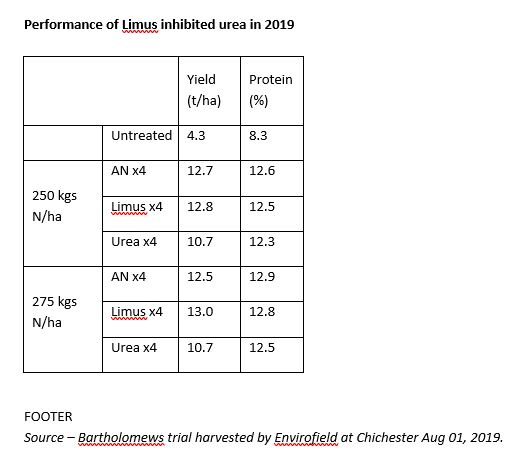

Eloise Griffin provides arable technical support at Bartholomews and was responsible for the 60-plot trial on the Chichester plain. “Our previous trials work has shown a little and often approach is the best way to apply nitrogen to the crop, so the protocol included four applications of equal amounts of nitrogen applied at GS30, GS31, GS32 and GS39 and investigated two total nitrogen rates, 250kgN/ha and 275kgN/ha. The nitrogen was applied as AN, straight urea and Limus-treated urea,” she explains.

“At the first application timing (13/03/19) polysulphate was also applied to the trial area as a source of SO3. The conditions were cool and windy, with little rainfall so the soil moisture was low. Overall the crop (Zyatt winter wheat) was looking N-deficient coming out of the winter,” she says.

At GS31 (26/04/19) the dry conditions were beginning to bite. “With temperatures still cool and with little rainfall since the last application, the soil was looking very dry and the crop was potentially starting to suffer.”

For the third application (10/05/19) conditions had changed, with warmth and plenty of rainfall. “The crop was starting to move through its growth stages very quickly with lush growth in the treated plots. By GS39 (20/05/19) the crop was looking very healthy with good soil moisture levels,” explains Eloise.

Tissues samples were taken during the course of the trial and the results showed up interesting differences between the different nitrogen forms, she adds.

“The AN and urea-treated plots ran out of nitrogen in the leaf much faster than the Limus-treated plots. Here there appeared to be a drip feed effect, where the nitrogen lingered in the leaf tissues for much longer. This was most apparent towards the end of the season when there was more soil moisture available.”

Assessments of tiller numbers and GLA didn’t reveal any significant differences between treatments and Eloise describes the plots as looking very similar but the harvest results told a different story.

“The Limus-treated plots yielded 2.3t/ha more than the standard urea at the highest rate of total N (275kgN/ha) and 2.1t/ha more at the lower rate (250kgN/ha). Both were statistically significant differences.

“The differences between the AN and Limus-treated plots weren’t significant, with a very comparable performance between the two different forms (see table),” she comments.

Andrew believes the trial provides some reassuring information about the performance of Limus-treated urea against the other forms, particularly in a season where soil moisture was lacking at the early application timings.

“We’re looking for ways to improve the efficiency that crops can take up and utilise nitrogen fertilisers to minimise the amount lost to the environment and to improve production efficiency.

“We’ve found an improved crop recovery by taking a little and often approach to N-application and the fact that the Limus-treated plots out yielded the AN by 100kg/ha suggests the highest nutrient use efficiency in the Chichester trials,” says Andrew.

Perhaps the most interesting outcome of the trial is the effect each treatment has to the bottom line. Bartholomews’ margin over input calculations at current market prices put the Limus-treatment £35/ha ahead of AN at the 250kgN/ha rate.

“With N-recovery only about 60-65% depending on soil type, every percentage point improvement counts but there’s still a lot to learn about crop nutrition. The 16% uplift in performance compared with untreated urea certainly gives me the confidence to recommend Limus-inhibited urea on farm,” he says.

Richard says the Bartholomews trial builds on the portfolio of work BASF already has supporting the product and believes Limus offers a good technical solution to growers who prefer AN as their source of nitrogen.

“Trials consistently show that Limus-treated urea works as reliably as AN, giving equivalent field performance while generally being cheaper,” he comments.

Limus clear winner in trial

James Faulkner farms 1350ha at Peldon in Essex, renowned for being the first location where resistance in blackgrass was identified in the early 1980s. With blackgrass control a key priority, he has a diverse rotation which includes oilseed rape, winter wheat, peas, spring barley, potatoes and grass, as well as rye and maize for AD. In contrast the farm also grows a block of continuous winter wheat.

The farm has graduated from using granular urea to UAN in recent years and after seeing Limus Clear in trials, James invited BASF to run a trial in winter wheat on his holding.

“I’ve used nitrogen inhibitors in maize before because the timing of application and a very open crop means preventing losses of ammonia in maize are even more important than in wheat. In the trial where I first came across Limus Clear, there were two different inhibitor products and it was Limus that gave the greatest yield increase. So I was keen to have a closer look at it,” he says.

Canopy assessments were made in July to assess green leaf area (GLA), leaf length and leaf width by leaf layer on a grid of points across the trial on James’ farm. The Limus-treated crop had significantly higher leaf area on leaves three and four, a significantly higher GLA on the flag leaf and a higher total leaf area index compared with the untreated. The measurements on other leaves where Limus was used also showed a trend towards larger and greener leaves but the differences weren’t significant.

Even though the detailed assessments showed differences, these weren’t visible in the trial. So it was with some surprise that James received the yield results, analysed using the ADAS Agronomics approach.

“The average yield of the farm standard (Limus untreated) crop was 12.78 t/ha. The modelled effect of the Limus treatment was to increase yield by 0.29 t/ ha, which was a statistically significant difference,” he says.

“It didn’t seem like the type of season that Limus would have big effects. The UAN went on as a split application in April and there were rainfall events soon after both applications,” he adds.

A margin over input costs analysis on the trial showed the addition of Limus Clear to UAN provided an additional £31.80/ha based on a wheat price of £135/t. Encouraged by the results, James plans to use Limus Clear in the future and says it’s a product that will provide him with added flexibility.

“It’s easy to take with you on the sprayer because the dose rate is relatively low. Then you can add to the tank, or not, depending on the weather conditions at the time.”

Research Briefing

To help growers get the best out of technology used in the field, manufacturers continue to invest in R&D at every level, from the lab to extensive field trials. CPM Research Briefings provide not only the findings of recent research, but also an insight into the technology, to ensure a full understanding of how to optimise its use.

CPM would like to thank BASF for sponsoring this Research Briefing and for providing privileged access to staff and material used to help bring it together.

Although in recent years, BASF is not a name normally associated with fertilisers, it belies a history going back over 100 years. At the turn of the last century, BASF enabled industrial, large-scale production of mineral fertilisers with the revolutionary Haber-Bosch process. In the last 30 years, BASF has focused its R&D efforts on the development of fertiliser additives to reduce nitrogen losses and increase efficiency. Limus is the first technology available in the UK to come from this R&D pipeline. Limus protected granular urea is available through Bartholomews, Thomas Bell and COFCO. Limus Clear, a product for tank-mixing with liquid UAN fertilisers, will be launched in the new year. For more details on Limus, please see www.agricentre.basf.co.uk/limus