Water companies are working with farmers to reduce the amount of oilseed rape herbicides that find their way into drinking water supplies. CPM reports on a new study involving clethodim.

Farmers are the guardians of the catchment. As long as they’re fully aware of the risks, they’ll take good care of it.

By Tom Allen-Stevens

New research suggests field rates of residual oilseed rape herbicides may be cut without loss of overall efficacy on blackgrass when used in sequence with clethodim (as in Centurion Max). The study, led by independent specialist Dr Stephen Moss, has shown good results from the sequences, even in resistant blackgrass situations.

Targeted rate reductions could significantly reduce the amount of OSR herbicides found in ground and surface water, says Danny Coffey, catchment officer for Affinity Water, that commissioned the research. “Carbetamide and propyzamide cause us serious problems as we have a stringent drinking water quality standard for pesticides we must meet.”

The study focused on two water supply catchments in South Herts, an area where Affinity Water relies heavily on groundwater supplies and where detections of carbetamide and propyzamide above the permitted level of 0.1 parts per billion are frequently exceeded. “It’s an area where clay straddles chalk and there are direct pathways from surface to groundwater which pose a risk to our abstractions,” explains Danny.

“The challenge differs from metaldehyde. We can treat the OSR herbicides from raw water we abstract up to a certain concentration, but they can be detected in some instances at significantly higher concentrations than treatment can manage. At this point we have to cease our abstraction and source water from elsewhere at a significant cost, so we’d much rather work with growers to find ways to prevent the chemicals from entering the system in the first place.”

On farms in these catchments, herbicide-resistant blackgrass has become a major problem, reports Stephen, resulting in growers abandoning ACCase inhibitors, which include clethodim and cycloxydim, relying more on residual herbicides that have retained their efficacy. “Propyzamide use rose nationally by 23% between 2016-18,” he says. “Clethodim is much less affected by resistance than other ‘dim’ herbicides, however. It can’t totally replace propyzamide and carbetamide, but there should be potential for reducing the use or dose of follow-up herbicides, at least on fields with a high risk of leaching.”

Stephen explains the most common ACCase target-site resistance (TSR) mutation, known as Isoleucine-1781-Leucine, is the one usually identified in a standard petri-dish resistance test in which cycloxydim is the herbicide used. But previous studies have shown clethodim efficacy is affected much more by the Aspartate-2078-Glycine mutation, which is still relatively rare in the UK. “Although it’s been in widespread use for many years in some parts of the world, such as Australia, clethodim is a relatively new herbicide for UK growers,” he points out.

So Stephen set up some petri-dish assays with Agherba Consultants to test levels of resistance of 20 blackgrass populations to cycloxydim, clethodim and pendimethalin. “These were mainly collected from wheat crops in summer 2019. Four older, well characterised populations were also included as resistance reference samples.”

The 16 test samples were mainly from fields in the South Herts catchments, including four from a field later used for an in-field study, while three from Warwicks were used to put the local results in a broader context. The four reference populations were: a susceptible population from an area of Broadbalk at Rothamsted that has never received any herbicides; one from Notts known to have the 1781 ACCase mutation; one from Peldon in Essex, known to have high enhanced metabolic resistance (EMR) and high ALS TSR, but no ACCase TSR; and one from Yorks characterised in previous studies as being an average, representative UK population. Clethodim was tested at 0.4 and 1 parts per million, with cycloxydim and PDM tested at 5 ppm.

“We used two doses of clethodim as the higher dose may mask levels of resistance you’d identify at the lower dose,” explains Stephen. “The reference samples performed as you’d expect – 100% control of the Broadbalk sample with both clethodim and cycloxydim, while there was very poor control of the resistant Notts sample with cycloxydim and the Yorks sample was intermediate.”

Clethodim was much more effective on the resistant reference samples, especially at the 1 ppm dose. “On the test samples, the lower dose gave an overall mean control of 45.4% – very similar to cycloxydim (43.9%) – and some degree of insensitivity to clethodim was recorded with all test populations. But clethodim at 1 ppm gave much better control than cycloxydim – a mean value of 85.2%. The results show clethodim is relatively much more active on blackgrass that has some degree of resistance to cycloxydim.”

So how would this translate into the field? Stephen notes you can’t make a direct correlation, although cycloxydim is applied at 150-200g/ha and clethodim at 120 g/ha. “So clethodim’s used in the field at a slightly lower dose, but the petri-dish results suggest equivalent control at 8% of the cycloxydim concentration and much better control at 20%. The results show it’s worth getting your blackgrass tested for clethodim resistance, even if you know it has ACCase TSR.”

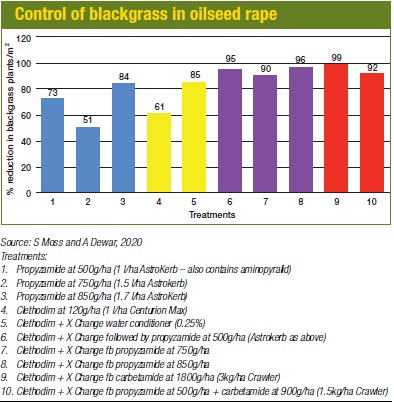

A trial was set up in one of the fields in the catchment from where four samples of blackgrass had been tested in the petri-dish assays. Averaging results from the two clethodim doses, these had shown between 42-66% control – at the more challenging end of the spectrum. The OSR crop had been drilled in mid Aug and then 10 herbicide programmes were applied plus two untreated across four replicates. The clethodim was applied in mid Oct and the propyzamide and carbetamide applied mid Nov.

“The OSR had established well by the time the herbicide was applied, to the extent we were worried the crop would shield the blackgrass,” reports Stephen. “When the assessments were made on 9 Jan the population in the untreated plots averaged 21 plants/m², which is a relatively low density – we’d have preferred 50-100 plants/m², although the findings are still relevant. Good control was carried right through to harvest and would still have been perfectly acceptable with a higher weed infestation.”

Control with either the propyzamide (blue columns in chart) or clethodim (yellow columns) used alone wouldn’t have been good enough, especially at higher weed populations, he notes, “Although control from clethodim with a water conditioner was particularly impressive.”

But it was the sequences that gave by far the best results (purple and red columns), with reduced rates of propyzamide performing as well as higher doses. “These support the view that it might be possible to use lower rates of propyzamide following good control by clethodim. Alternatively, carbetamide or a reduced dose mixture of carbetamide and propyzamide might be used.”

Stephen stresses that reducing rates of propyzamide wouldn’t be appropriate where there are high populations of blackgrass. But it could make a real difference to the amount of the herbicides that end up in groundwater, notes Danny. “If a reduced rate strategy was targeted in the right areas, it would significantly cut the risk for certain pathways.

“What we’re aiming to do is work with growers and use this in combination with other strategies to reduce herbicide exceedances. Farmers are the guardians of the catchment. We’ve found that as long as they’re fully aware of the risks and the different approaches available to mitigate these, they’ll take good care of it.”

Good stewardship vital for OSR herbicides

Whether clethodim works for you is largely down to the type of TSR you have, notes Rob Adamson of UPL, manufacturer of Centurion Max.

“The mutation we worry about with clethodim is 2078 – the one that confers resistance to it,” he says. “Other ‘dim’ herbicides, including cycloxydim, will fail if the blackgrass has the more common 1781 mutation. But we believe 2078 affects around just 3% of UK blackgrass.”

Efficacy is dose responsive and varies with water hardness. “We find most problems growers experience with control are less to do with resistance and more down to application procedure. It’s therefore critical to not drop the dose below 1 l/ha and to always follow up with another mode of action, especially where resistance is suspected,” he adds.

Rob advises growers follow the stewardship guidance on clethodim:

- It shouldn’t be tank-mixed with other products, including adjuvants, herbicides, fungicides or nutrients although an insecticide is allowed.

- A non-wetted water conditioner will improve efficacy in hard water areas.

- Use from four true leaves of the OSR crop, but not after 15 Oct.

- Do not spray the crop 10 days before treatment or 14 days after.

- Do not apply at temperatures below 7°C, when crop is stressed or suffering pest damage.

Dr Alison Hall, herbicides product manager at Adama, that manufactures Cohort (propyzamide) and Crawler, notes that all herbicides should be used responsibly and always in accordance with the relevant stewardship guidelines.

“For maximum efficacy, we’d always recommended sticking to recommended (label) rates. Whilst we take on board the sentiment of the trial work and the need to protect water quality, real world cropping conditions means we can’t endorse the simplified usage of reduced rates,” she adds.

Good stewardship is essential, adds Kerb (propyzamide) and AstroKerb manufacturer Corteva. “It protects the environment, ensures robust efficacy on target pests and weeds and is an important component in any anti-resistance strategy,” says a spokesman.