Luxinum Plus promises a significant step-up in grassweed control for UK growers who keep in place good herbicide stewardship programmes. CPM tells the story of how this new mode of action came to market.

Luxinum Plus delivers a 20% uplift in performance against blackgrass – it’s the new building block for autumn herbicide programmes.

By Tom Allen-Stevens

Heralded as a “new dawn for weed control”, Luximo is something of a double first, according to BASF UK and Ireland head of technical management for agricultural solutions Rob Gladwin.

“Firstly, it’s 21 years since the current market standard, flufenacet, was registered for use in the UK market; and secondly, cinmethylin, branded as Luximo, is the first wholly CRD-managed active substance approval gained by any manufacturer since crop protection regulation was repatriated following Brexit,” he says.

But although it represents the first new blackgrass herbicide mode of action (MoA) in Great Britain for decades, the active ingredient cinmethylin is actually far from new. And as for any change in management practice it’ll herald, it’s very much business as usual, with those keen to stay one step ahead of grassweeds encouraged to maintain all the cultural controls.

Luximo wasn’t so much discovered as re-discovered, explains Bernd Sievernich, who has been working in research and development at BASF’s Agricultural Centre in Limburgerhof, Germany, since the late 1980s.

Bernd Sievernich believed the chances of finding a new post-em cluster of chemistry was simply unrealistic, but then he remembered cinmethylin.

“I first came across cinmethylin in 1988 when Shell published some information on its use in transplanted rice,” he says. “It was released under the brand name Argold, but not intended for many markets, so wasn’t widely used. It hung around for a few years and then the active ingredient disappeared.”

In 2000, BASF acquired American Cyanamid, which had in turn acquired Shell, along with its herbicide portfolio. “There was some quite interesting material in it that hadn’t really emerged – picolinafen is a good example. We did some work on a number of herbicides that hadn’t come to market but had potential, and one of these was cinmethylin.”

Bernd and his team carried out glasshouse trials on the compelling chemical, not just on rice and the handful of other crops Shell had worked on, but also cereals. “Shell had done some basic research but hadn’t really followed it up,” he continues.

“In paddy rice they’d used a very low rate of just 100g/ha of ai. We included it in cereal crops at three to five times that rate, and the results were promising, particularly on blackgrass.”

But at the time, ACCase inhibitors, such as clodinafop and fenoxaprop, were widely used and Atlantis (mesosulfuron+ iodosulfuron) became the rising star. “Post-emergence chemistry dominated the herbicide market. There was hardly any interest in a soil-acting residual. So once again, the active was put to sleep.”

As the 2000s moved into the 2010s, the post-em products began to show their weakness – not just target site resistance, but also enhanced metabolism. “It was a problem for us in product development – there was a call for a herbicide with a new MoA, but to believe there was a new post-em cluster of chemistry was simply unrealistic. Then we remembered that promising soil residual, cinmethylin,” recalls Bernd.

Luximo has been included worldwide within independent and proprietary field testing, including at this Italian ryegrass site at Kirk Hammerton in North Yorkshire.

The files were dusted off and reviewed, the prospects for cinmethylin revived. But the tests had only progressed as far as the greenhouse. “We didn’t know how it would perform under field conditions, so that’s where we focused our work. Here, an important difference was how it would fare in dry soils – the tests in the glasshouse had always been irrigated.

“The results really were exciting – cinmethylin was clearly outperforming both pendimethalin and flufenacet. There was also a reliability of performance over a range of field conditions, and that’s a key factor for residual chemistry. We found its dependency on soil moisture is lower than with other products used currently.”

The field trials also established the rate – 500g/ha of active ingredient was found to offer effective control of a range of grassweeds. But one important piece of the R&D jigsaw remained unresolved: registration and approval.

“We already had something of a head start with cinmethylin since it had been used historically in some countries,” he notes. “But the old regulatory work that underpinned this would never meet today’s stringent requirements of the EU and the UK, where the chemistry had never been commercialised.”

Bernd explains that the approach BASF takes to product approval is to align the associated market introduction to the anticipated regulatory environment, rather than the parameters that exist at the time of first field testing. “We want Luximo to have a good, long lifespan in commercial use. So with this sort of chemistry, the elements to look at closely were the potential for groundwater contamination and also ecotox – effects on flora and fauna.”

Here Luximo scores well, with none of the halogenic elements, such as chlorine, that could lead to an issue. Nonetheless, it was taken through particularly rigorous tests, he points out, to ensure any regulatory queries would be addressed before they were asked.

“Of course, there is still the worry of resistance. So far, we haven’t found any evidence of resistance in target weed species to Luximo. But we have learnt from cases of resistance to glyphosate that we should never believe resistance to any herbicide, including Luximo, will never develop,” highlights Bernd.

What Luximo does have in its favour, however, is its MoA. In early work with cinmethylin, this was classed as ‘unknown’, but science has moved on and more recent work undertaken by BASF has helped to establish that it’s an inhibitor of the fatty acid thioesterase.

This interferes with the formation of fatty acids at an early stage, which has a direct consequence on plant development, as they are important components of cell membranes. Luximo is primarily taken up through roots, but also acts on germinating seeds so will catch susceptible grassweed seeds on the soil surface.

That sets it apart from all the other soil residual, grassweed herbicides available, which mostly belong to Herbicide Resistance Action Committee (HRAC) MoA group 15 and inhibit very long chain fatty acid synthesis. Cinmethylin is a benzyl ester, officially belonging to HRAC group 30.

This in itself marks a significant milestone for grassweed control – a new alternative MoA to the pre-emergence industry standard flufenacet that cereal growers in the UK have heavily relied on since its introduction 21 years ago. The news of this novel development was first published in CPM in October 2016, after it was revealed exclusively to British technical journalists at a BASF global press briefing.

Since then, it’s been included worldwide within independent trials as well as proprietary field testing undertaken by BASF. Here in the UK, a select few of BASF’s Real Results Pioneers have included it in farmer-led field trials and seen for themselves how it performs under real-world conditions.

As Luximax, the new active was first approved for sale in 2019 in Australia, where growers battle against highly resistant ryegrass. And few growers here will have missed the build-up to the British launch in June this year of Luxinum Plus. News of its registration was another landmark moment – the first, new active substance approval through the repatriated GB regulatory process.

Luxinum Plus delivers 500g/ha of Luximo at the recommended field rate of 0.7 l/ha, reports BASF’s herbicide business development manager Stuart Kevis. “In the field, under UK conditions, Luxinum Plus delivers a 20% uplift in performance against blackgrass – it’s the new building block for autumn herbicide programmes,” he says.

Stuart Kevis notes that Luxinum Plus with Stomp Aqua delivers a level of control currently only seen in heavy autumn herbicide stacks.

“We’ve analysed results from 106 pre-em trials, carried out over four years, across different conditions, in high and low blackgrass situations. While flufenacet on its own offers 56% control, solo Luximo steps this up to 78%.” A smaller dataset for Italian ryegrass shows a 27% uplift in control, he adds.

Presented as a flufenacet replacement, for this season it comes in a 5ha co-pack with Stomp Aqua (pendimethalin), recommended at 2.0 l/ha. “You get a level of control from this mix currently only seen in heavy autumn stacks – 21 trials over three years indicate it’s comparable with Crystal (flufenacet+ pendimethalin) plus diflufenican in sequence with Avadex (triallate). Add Avadex to a Luxinum Plus and Stomp programme and you get an extra nine percentage points of control,” he adds.

Luxinum Plus is a true pre-em product – although there’s label allowance for post-em applications, BASF recommends spraying within 48hrs of drilling. As a soil residual, seed must be drilled to at least 3cm depth and performance will be best in good, moist seedbeds, with little surface trash. Although the label indicates a water volume of 150-300 l/ha, BASF supports a rate as low as 100 l/ha.

This nudges Crystal out of the prime pre-em slot, but it’s far from dropped altogether, notes Stuart. “Where a follow-up is needed, you can apply Crystal, although note you’ll already have applied almost half the allowable 2000g/ha dose of PDM.” For now, Luxinum Plus is approved only for wheat, and he highlights Crystal’s strengths in winter barley and against annual meadow grass. Subject to approval, Luximo will come in other co-formulations next season, but don’t expect to see it in a mix with flufenacet.

The key to maintaining Luximo’s efficacy will come down to how it’s managed on farm, however. “It’s absolutely crucial that integrated measures are embedded into growers’ weed-control programmes to prevent and mitigate resistance development,” stresses Stuart.

“All of the current advice on using crop rotations, later drilling and prevention of weed-seed return must be followed as these remain the bedrock of an effective grassweed control strategy. It’s also really encouraging to see mechanical hoeing and harvest weed seed control coming in, as these will become just as important as additional tools in the box in the battle against blackgrass,” he notes.

“What’s more, Luxinum Plus is less reliant on soil moisture, but that doesn’t mean you should drill in bone-dry conditions. That said, it consistently outperforms current standards and sets the new benchmark for grassweed control. Used wisely, it will continue to do so for many years to come,” concludes Stuart.

Resistant UK blackgrass checked by Luximo

Richard Hull warns growers can select for lower susceptibility through lowering the dose rate, spraying in unsuitable conditions, at a less than ideal timing, or through poor application.

Few grassweed seed collections have the breadth of resistances of the blackgrass gathered since 2014 as part of the Blackgrass Resistance Initiative (BGRI) network, now held by Rothamsted Research.

“We have the full range of non-target site resistance found in UK populations,” notes Dr David Comont, ecologist at Rothamsted. “Sensitivity to fops, dims, ALS-inhibitors, flufenacet and glyphosate have all been characterised, with some samples very sensitive and others worryingly resistant.”

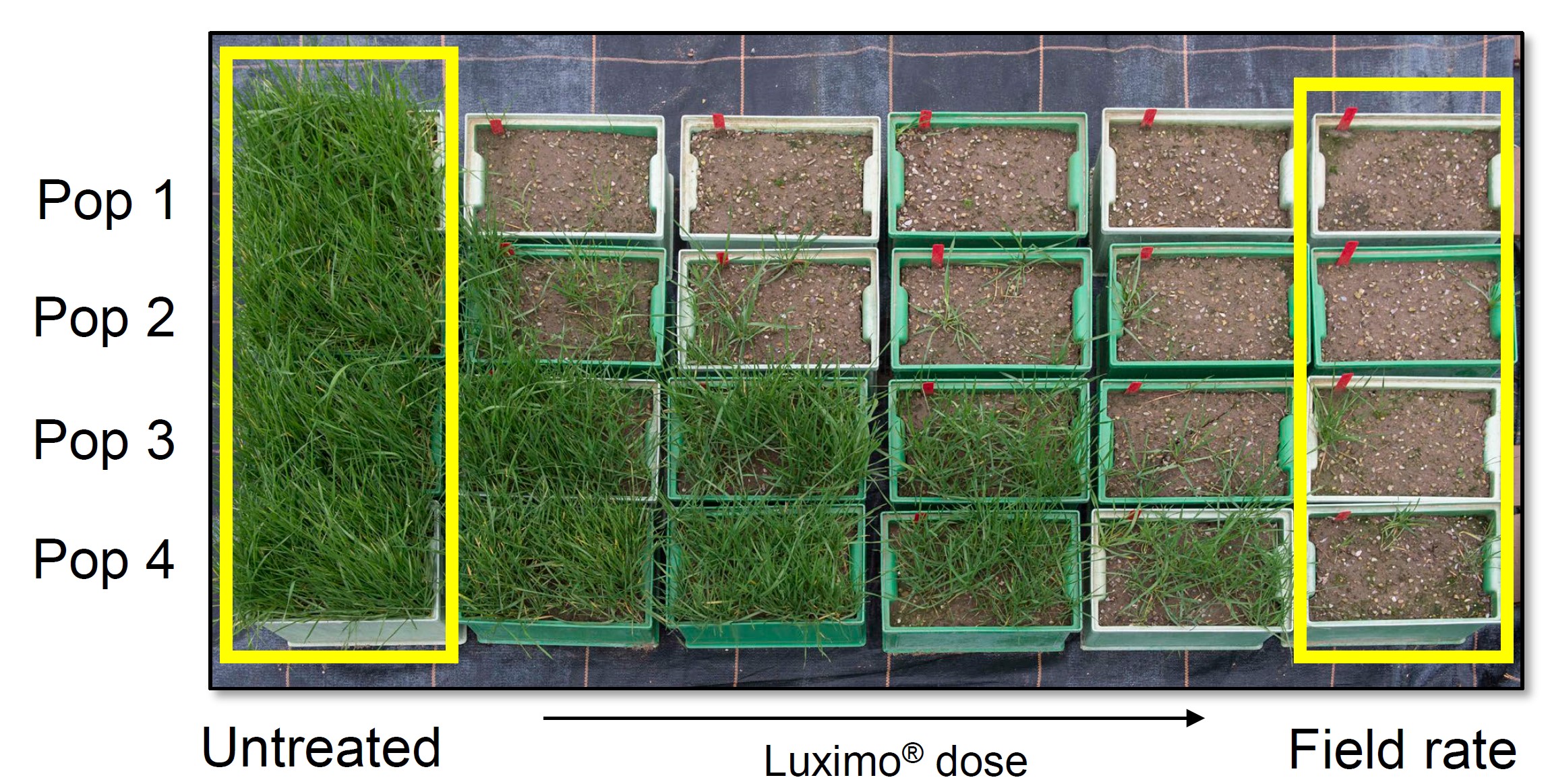

The collection, drawn from 180 field sites across England, presents the ideal opportunity to test the efficacy of Luximo, explains his colleague, Richard Hull. “We focused only on the most recent samples collected in the tests we ran. We wanted to establish the efficacy of Luximo on UK populations before they had been exposed to cinmethylin, and the potential for cross-resistance, for populations where a lower sensitivity had built up.”

The screening showed 500g/ha of cinmethylin is effective at controlling blackgrass, but three populations showed significantly lower susceptibility at reduced rates.

David explains that non-target site resistance is related to the production of proteins, caused by a complex set of genes. Repeated herbicide exposure leads to changes in gene expression, causing production of some proteins to be upregulated. This allows a frequently treated blackgrass population, a greater ability to shrug off the effect of an applied herbicide. “So it’s possible that resistance to one MoA will cause a plant to be genetically predisposed to be resistant to cinmethylin, even though it’s never been exposed to the herbicide.”

In all, 100 samples were treated, including three from reference populations, under controlled conditions. Where populations were found to have lower sensitivity, these were tested outside, exposed to the elements.

“All of our screening showed the 500g/ha dose of cinmethylin is pretty effective at controlling blackgrass – on average 97.6% control and that’s a consistent result across all populations,” reports David.

But three populations, including a reference sample from Peldon in Essex and one each from fields in Oxfordshire and Lincolnshire, showed significantly lower susceptibility to Luximo at a lower than field-rate dose, notes Richard. “This shows that you can select for lower susceptibility through lowering the dose rate, spraying in unsuitable conditions, at a less than ideal timing, or through poor application.”

One Italian ryegrass population from Essex, found to be resistant to flufenacet, was treated with Luximo, adds David. “The results are quite stark at the full field dose of Luximo, with almost complete control, compared with a full dose of flufenacet that barely touched the ryegrass, although this was just one population.”

While the grassweed tests were on field populations, they were also carried out on samples that had been selected, through repeat applications in the glasshouse, for a high degree of resistance to pendimethalin, flufenacet and Atlantis. “These tests show there is no direct cross-resistance to Luximo with other herbicide MoA, and that’s good news as strategic use of the chemistry available should help growers protect its longevity,” notes David.

“But for any herbicide, resistance is just a matter of time. So it’s important to kill survivors through non-chemical means before they seed and to apply the right dose in the right conditions. Above all, maintain cultural controls, such as later drilling and spring cropping, to take the pressure off the chemistry toolbox,” he advises.

Innovation Insight

CPM would like to thank BASF for kindly sponsoring this article, and for providing privileged access to staff and material used to help put the article together.

This article was taken from the latest issue of CPM. For more articles like this, subscribe here.