A flagship technology based on a unique strain of nitrogen-fixing bacteria is gaining traction thanks to its consistent performance in on-farm trials, offering growers an alternative, sustainable approach to crop fertilisation. CPM investigates the science behind Encera.

“Encera works by systemic biological N-fixation – entering the plant through its cells.” JOE GRIFFITHS

By Janine Adamson

Although fertiliser prices have returned to a level of normality since the eye-watering highs of a few years ago, in many ways, what the experience did do, was shine a timely spotlight on how volatile that aspect of the industry can be.

Coupled with a drive towards improved sustainability and de-carbonisation across the entire supply chain, this has led to increased scrutiny when it comes to sources of nitrogen, believes ProCam’s Phil Burrell.

Having formerly worked in the fertiliser sector, he acknowledges that the concept of nitrogen use efficiency (NUE) is nothing new, but says grower awareness is now far greater. “When nitrogen prices escalated it made people think twice about their approach to crop nutrition, which isn’t necessarily a bad thing.

“And regardless, even in conventional years, nitrogen is often the greatest investment when it comes to crop inputs, therefore improving NUE should be a priority,” states Phil.

In the first instance, this could mean optimising the quantity of applied nitrogen a crop receives based on soil and tissue testing. However, innovation taking place at a laboratory in York is striving to promote a new approach – where a plant-colonising bacteria leads the way.

Gluconacetobacter diazotrophicus, known as Gd, is a naturally-occurring bacteria which converts atmospheric nitrogen into a plant-usable form. It was originally found in Alagoas, Brazil, and was isolated during sugarcane analysis due to its specific features.

It was these attributes which piqued the interest of researchers at the University of Nottingham, and as a result, the company Azotic was formed. By patenting a unique strain of Gd, AZ19, the firm has since released its bacteria-based technology to the UK market under the Encera brand.

Crucially, whereas nitrogen fixation was previously only available to leguminous crops which utilise rhizobia, by colonising cells throughout the plant, Encera opens up this valuable pathway for all crops, says technical sales manager, Joe Griffiths.

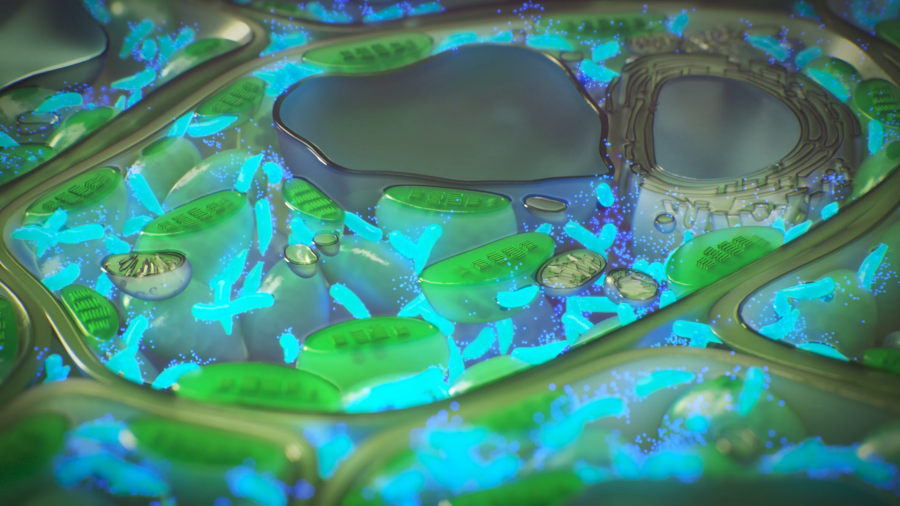

“Encera works by systemic biological N-fixation – the bacteria directly enters the plant through its cells via multiple entry points: its stomata, trichomes and roots. This is what makes it unique and therefore different to other N-fixing products on the market, where most bacteria live within the soil or between the cells.” he explains.

Once it’s entered a plant, Gd continues to multiply within cells, fixing atmospheric nitrogen when and where the plant requires it throughout the growing season. However, being a gram-negative, non-spore-forming endophyte, it requires a host to survive, adds Joe.

“Gd is highly motivated to get inside the plant as soon as possible to form a symbiotic relationship. This critical interaction allows the plant to provide sugars to Gd in exchange for nitrogen – a beneficial exchange.”

The ultimate aim of Encera is to provide a constant, season-long supply of nitrogen, helping to plug the gap when a crop may find it difficult to source its own. In being an alternative source of nitrogen, it’s not susceptible to the same constraints faced by synthetic fertiliser such as adverse soil or environmental conditions.

“For example, soil-based nitrogen isn’t always available or accessible by the plant due to waterlogging, drought or lock-up,” highlights Joe. “But the nitrogen fixed by Gd doesn’t have to be translocated – it’s available directly in the plant cells.”

According to Phil, this helps to de-risk the management of applied nitrogen. “The pressure is only increasing, whether that’s from a regulatory or potential tax perspective, or, from the significant drive to reduce carbon in the system.

“There’s so much unknown surrounding the fertiliser industry; using a product like Encera means growers can take a level of control and mitigate the impact of those threats which loom on the horizon,” he says.

However, he also believes it’s important to understand the end goal from an individual farm’s perspective. “For those with a lower yield potential this could involve using Encera to complement or compensate, and therefore achieve an overall percentage reduction in applied nitrogen and better ROI.

“Or, in the case of those striving to break through an NUE barrier for higher yield, Encera would be in addition to full rate applied nitrogen.”

UK trials suggest both approaches can offer measurable benefits, with Azotic working to deliver robust, independent datasets to help instil confidence in its innovative technology.

For one, work undertaken by Eurofins last year across five winter wheat trial sites indicates that on average, Encera offers a 0.32t/ha uplift at a full rate nitrogen regime, compared with the farm standard. Whereas for a 25% nitrogen reduction, around 40-50kgN/ha, Encera compensated while increasing the yield by an additional 0.16t/ha over the farm standard.

Then in potatoes, a crop which Joe believes can significantly benefit from Encera, trials undertaken by VCS in 2024 indicate when applied once at row closure, the product can deliver a 9t/ha yield uplift.

“It’s certainly encouraging to see that independent work matches in-house trials – we can comfortably state that in cereals, Encera has the potential to replace or fix 15-25% of applied nitrogen, equating to around 30-40kgN/ha.”

To achieve this, Joe says it’s best to apply Encera early in the season at around T1 timing in wheat, or row closure in potatoes. As the product is based on live bacteria, daytime temperatures should be 10-25oC to ensure the Gd is active and able to multiply.

Azotic has also been using its facilities in York to further develop Encera, moving from a liquid product to a room temperature dry formulation with a two-year shelf-life. “This is an important factor – the product has to fit into existing crop management approaches without specialist storage conditions or applicators.

“Equally, Encera is fully tank-mixable and thanks to a low use rate of 12.5gai/ha, is highly concentrated,” highlights Joe.

Although supported by various peer-reviewed academic papers and independent trial work as highlighted above, Gd’s efficacy remains subject to scepticism in the trade. As such, this has meant further laboratory work for Azotic.

“We wanted to prove that the nitrogen fixation was a direct result of the application of Encera,” comments Joe. “So this involved developing a form of the bacteria without the nitrogen-fixing gene, which was compared with the bacteria in its true natural form.

“We found that although the adapted gene offers other benefits to the plant aside from N-fixing, the experiment proved that nitrogen-fixation – as achieved through the bacteria in Encera – was the primary factor driving yield improvement (see graph).”

While some reticence may remain in the UK, Encera is rapidly gaining pace with growers across the pond where the product is marketed under the Envita brand. Canada-based Tom Tregunno from Azotic says: “Although it’s been developed in the UK, we’re seeing tangible results in the US, particularly for crops such as maize.

“Grower-led trials indicate benefits such as improved cob uniformity and cob set, a boost in overall cob size, plus a reduction in tip back. It reduces a lot of in-field variability, as demonstrated through yield monitor data. But seeing is believing and we’re experiencing a steady uplift in the adoption of Envita’s technology,” he adds.

According to Tom, because the product has been trialled across a variety of scenarios globally, with positive and consistent results, he believes it offers much flexibility to growers. “The US landscape is highly variable yet Envita is delivering reliable results, therefore we say it ‘fits your farm’.

“However, all growers require evidence of a product working well locally in their climate, using their equipment on their land. At the same time, Azotic is working to maximise Envita for northern climates to understand how best to use it in a situation where there could be a yield plateau.”

Despite the fact that many questions regarding the technology remain unanswered, he adds that one certainty, is that it works.

To conclude, Phil stresses Encera must be recommended based on its technical merits, rather than traded as a commodity. “This is where it’s different to conventional fertiliser – because Encera almost seems too good to be true, it requires guidance and insight.

“Therefore the data and science to support its use is critical to ensure its long-term adoption by understanding its position and the objective of its use.”

This article was taken from the latest issue of CPM. Read the article in full here.

For more articles like this, subscribe here.

Sign up for Crop Production Magazine’s FREE e-newsletter here.