Emerging from the muddy waters which have long surrounded the fields of specialist nutrition and biostimulants is a new generation of products underpinned by credible science. CPM visits Brittany to find out more.

This is the perfect moment for the adoption of greener technologies.

By Lucy de la Pasture

Fast forward a generation and current agronomy practices will likely be known as the chemical era, a time when high yields relied largely on inputs of synthetic pesticides and nutritional products, believes French farmer’s son, Hervé Balusson.

Hervé’s vision is for a ‘global and circular approach’ to agriculture using a natural resource that washes onto the beaches of his birthplace, Brittany. The founder and CEO of the Olmix Group, he believes that agricultural practices should benefit human nutrition as well as animal and crop production. With this in mind, Olmix has applied science to discover the specific properties of marine algae and how these can be used to advantage in farm animals, crops and humans to help reduce the use of fertilisers, pesticides, antibiotics and food additives.

“If we want to sustainably feed the planet, we need to produce more and do so more efficiently, using less resources. Utilising marine algae as the essential element in a wholesome and healthy food chain is one of the ways to meet this challenge,” he says.

Since its inception in 1995, Olmix has become a leading specialist in marine biotechnology and green chemistry, with €10M being poured into R&D each year (6% of turnover). “Innovation is the driving force behind our development and algae still have so much to teach us,” comments Hervé.

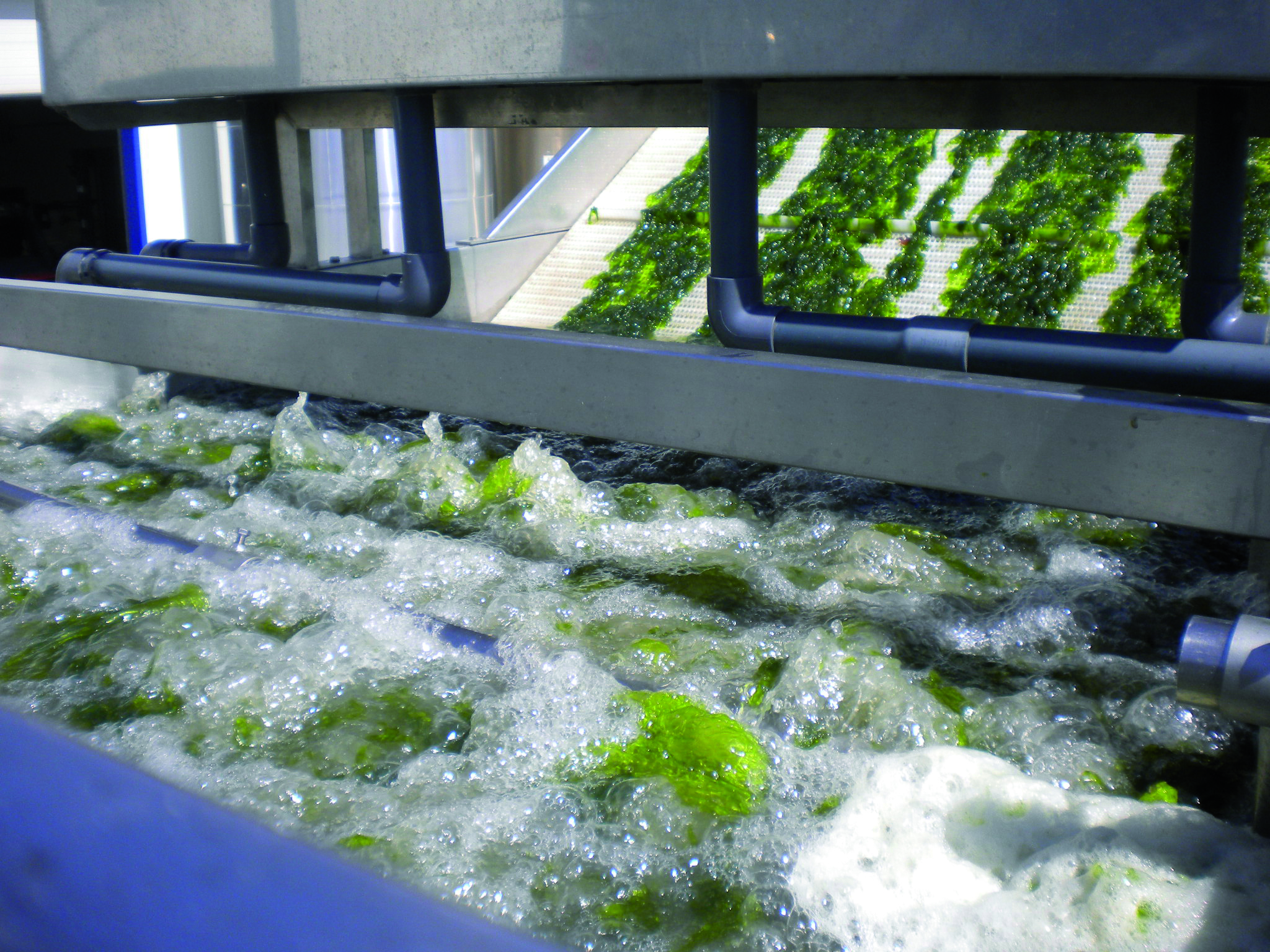

Seaweed needs to be processed quickly once harvested to ensure its extracts are of high quality.

To accelerate innovation the seaweed specialist has developed close collaborative ties with renowned research institutes such as the biological station of CNRS (French National Scientific Research Centre) in Roscoff, which is the world reference for the study of algae. It also has associations with INRA (French Institute for Agricultural Research) and many other universities.

The Olmix Group doesn’t just talk the talk, it walks the walk, demonstrating through its own farms and restaurants what can be achieved from farm to fork. It’s an important part of the Olmix philosophy to show it’s possible to produce antibiotic-free poultry and pigs and this is served in its Bréhan restaurant, set up to showcase the many culinary possibilities of algae.

Proof of the group’s R&D credentials lies in the human field where it has already identified three new molecules which have potential as medicines. One of these is for use in colon cancer and is in third stage clinical trials. Two further molecules have been found to have antidepressant effects and are also being evaluated in trials.

Crop production is the newest field to Olmix. The Plant Care division was set up in 2006 but work into exploring the potential of algae only began in 2012 when a major R&D programme was launched, explains Didier Blin, product manager for Plant Care.

“We’re not just another seaweed dealer,” he stresses. “We’ve produced a range of biosolutions that have a positive influence on all the physiological factors that impact yield potential.”

Olmix are unique in their speciality, he points out, having complete control of every step of the production process from sourcing to quality control of the end-products. “The quality of liquid algal extracts remains very dependent on the freshness of the raw material, so extraction must be performed very quickly after harvest.”

The fractionated seaweed extract is analysed so products contain the constituents needed to have the required biological effect at the time of application.

“A lot of seaweed is being simply processed and sold as a plant booster, but Olmix has a scientific understanding of what the molecules are actually doing at the genomic level,” says Chris Gamble, sales manager for UK specialist crop nutrition company Micromix, which has recently joined the Olmix Group of companies.

“There’s no muck and mystery in this process which employs state of the art lab equipment and an understanding of how the algae extracts interact with complex plant biochemistry,” he explains.

“The seaweed extracts we’re more familiar with in the UK are produced from brown algae. Olmix research has identified red and green seaweed species have a much greater biostimulant and elicitor effect on plants and it’s these that they harvest from the coastline of Brittany,” he explains.

Another distinction of the Olmix product range is that they’ve been developed to enhance the entire crop growth cycle, explains Bruno Daridon, Olmix R&D manager. “The integrated approach starts with soil conditioners, biological activators and organic soil improvers to enhance soil quality and resilience, increasing its microbial biomass and porosity while reducing erosion and fuel consumption.

“We’ve found seaweed extract applied to the crop has a biostimulant effect; improving nutrient-use efficiency and ability of the plant to withstand abiotic stresses (such as drought and pesticide application), modifying its redox status and enabling continued development of yield components. In trials, crops at harvest consistently contain a higher level of nutrients,” he says.

R&D has also identified a synergistic effect when seaweed extract and nutrients are applied in combination. The specialist knowledge in formulation and uptake developed at Micromix will help refine a range of seaweed plus nutrient products in the UK, believes Chris.

Already a paradigm shift in farming is underway and there’s a growing interest in helping the crop to help itself. The potential of seaweed extract to deal with biotic stress (pests and diseases) is an area Olmix is intensifying its R&D activity, working with external partners with the aim of gaining biocontrol registrations. Didier believes that even five years ago, agriculture wasn’t ready for such a change in thinking, but in his honest opinion, “this is the perfect moment for the adoption of greener technologies.”

Reducing pesticide use in practice

France is a country with a green government and consumers who want food that’s free from pesticide residues, explains Florian Tilly, technical manager at Olmix. This is demonstrated by the availability of smartphone apps that allow consumers to scan produce and wine labels to get information on whether they’re rated as ‘good’ or ‘bad’ where pesticide residues are concerned.

It’s a trend that Breton grower Fabien Bocher fully appreciates, so he’s been putting measures in place across his 68ha farm in Saint-Connec to meet consumer demands. His aim is to reduce his usage of pesticides and inorganic fertilisers on all of his crops, leaving him ready to take advantage of the higher prices he believes the market will eventually offer for food produced in this way.

Fabien grows a wide range of crops which includes winter wheat, winter barley, winter oilseed rape, flax, clover for seed, corn and potatoes. Cover crops are a requirement in his region where land would otherwise be bare over the winter and his preferred mix is phacelia, white mustard and black radish.

Seven years ago, Fabien took over the management of the farm from his father. He immediately replaced the plough with a system of min-till cultivation because the sandy clay loam soil had become difficult to work. He switched from inorganic to organic fertiliser, applying 4t/ha of chicken muck together with a bioactivator product from Olmix, Geo2, which works to help improve the soil structure and the ability of crop roots to explore the soil.

“Geo2 helps the transformation of organic residues to humus production and it doesn’t need to be incorporated,” explains Didier.

Fabien says it was a logical step to use this type of biological activator in his situation. “I trialled different amounts of Geo2 in one field using a range of rates from 150-900 kg/ha (standard rate is 250-300 kg/ha). At the higher rate, changes in soil structure were visible after a year but at the standard rate it was 2-3 years before I noticed more earthworms, a better structure and soil that was easier to work,” he explains.

His introduction to the Agroptim range of biostimulants was due to a mishap. He’d applied a herbicide with a PGR to a crop of barley and shocked it badly so turned to Agroptim to help the browned-off crop get over the shock. He now routinely adds 0.5-1.0 l/ha of the biostimulant to every herbicide he applies.

When it comes to fungicide use, Fabien has found that he’s been able to alter his approach by using a combination of good varietal disease resistance, sowing density and the Agromel range of products at GS31, GS32 and GS37-39.

“The biostimulant produces a stronger plant that’s more able to resist disease. I inspect crops frequently, monitor forecasts and then I only apply a fungicide when disease pressure requires it,” he explains.

He takes a similar approach to his 3ha of potatoes which he markets direct to the consumer, where he’s able to promote his technical choices in his marketing. He uses three different seaweed products on his potatoes, which he applies in a programme every 8 days in an ultra-low water volume of 70-80 l/ha.

“If blight pressure is high then I’ll apply a fungicide but if it’s low and blight isn’t forecast, then I just apply the seaweed.” He estimates he’s reduced his fungicide application by 40-50% this season, where disease pressure was admittedly low.

Marine algae offer many benefits

The red and green algae used by Olmix are very different to the brown algae, which in evolutionary terms are much younger, explains Dr Maria Matard-Mann, research projects manager at Olmix. “Green and red algae are genetically as different to brown algae as animals are to fungi,” she explains.

Algae are among the fastest growing plants in nature, with growth rates of up to 30% per day. “This natural resource is Nature’s second lung and plays a role as important as the rainforests, processing carbon dioxide and producing half of the Earth’s oxygen.”

What’s more, the utilization of red and green seaweed is sustainable, with no deep water harvesting necessary. “Red and green seaweed attach to the rocky coastline. When they have finished their lifecycle, the holdfast detaches from the rocks and seaweed washes up on to the beaches where it is harvested,” explains Maria.

The cold pocket of water enveloping the Breton coastline, along with its high tidal range (average of 10m), particularly suits red and green seaweeds – with 75-85,000t harvested annually in the region.

“The tough environment the seaweed grows in gives the Brittany seaweed its natural strength and capacity to respond to external abiotic and biotic stresses,” she comments.

The algae contain different molecules that have both a nutritional and biological effect on plants.

“They contain a complete cocktail of organic and minerals elements – proteins, vitamins and minerals – which are of nutritional benefit. But marine algae also contain plant hormones, polyphenols and marine-sulphated polysaccharides, which have a biostimulant effect on crops,” she explains.

And it’s the properties of its marine-sulphated polysaccharides that are of particular interest – carrageenan in red marine algae and ulvans in green marine algae. These contain rare sugars and have a unique structure that give the marine algae their special biological properties, including working as an elicitor (boosting the plant’s natural defences).

These unique but harmless marine molecules are seen as a threat when applied to terrestrial plants, triggering the plant’s defence mechanisms. By mimicking a pathogen attack in this way, the crop’s ability to resist pathogens can be improved in the short term, reducing reliance on fungicides.

Since plants don’t develop immunity, repeated applications are needed to maintain any improved resistance to biotic stress, adds Maria.

Components of marine algae

- Carbohydrates (20-70% of dry weight)

- polyanionic and sulphated polysaccharides: alginates and fucoidans (brown algae), carrageenans and agars (red algae); ulvans (green algae); insoluble carbohydrates

- Proteins (1-35% of dry weight)

- Minerals (10-30% of dry weight):

- potassium, calcium, phosphorous, magnesium, sulphur, iron, chlorine, manganese, iodine, copper, zinc, molybdenum, silicon

- Lipids (0.5-4% of dry weight)

- Pigments:

- phycobiliproteins (red algae), carotenoids

- Vitamins:

- A, B1, B2, B6, B12, C, D3, E, K

- Secondary metabolites:

- polyphenols, phlorotannins, steroids