Hutchinsons has carried out split-field comparisons, showing a £99/ha return using its Omnia Precision Agronomy platform. CPM investigates.

We’ve now proved that it pays, and it does so handsomely.

By Tom Allen-Stevens

Applying agronomy on a sub-field basis has for some time attracted the precision-farming enthusiast, and some pretty bold claims have been made about the benefits. But for the most part, growers still crop and apply inputs on a field or block basis, suggesting a general scepticism over whether such an approach actually yields a return.

Hutchinsons has now released results of on-farm split-field comparisons showing its Omnia Precision Agronomy platform brings a yield increase of 0.6t/ha, or £99/ha (based on a wheat price of £165/t). The results are statistically significant, robust, entirely due to the application of the system, and can be replicated by any grower, says board member and Omnia founder Mike Young.

Omnia adopts a multi-layered approach to assimilating agronomic data gathered from fields, says Nick Strelczuk.

“No one was more surprised at the level of the financial return than us. But it’s because we’ve developed a system that puts the agronomist/grower relationship on a sub-field basis.”

This has been the guiding philosophy behind Omnia, he says, that the company has developed for its 200 agronomists across the one million ha of crops they currently serve. “Our challenge was to convert the wealth of precision farming data our clients have into decisions delivered on a sub-field basis with the same level of detail and care as the whole-field advice we currently give. We’ve now proved that it pays, and it does so handsomely.”

The comparisons took place over the past year, with two fields in Lincs and one in Leics (see panel on pxx). Omnia adopts a multi-layered approach to assimilating agronomic data gathered from fields, explains precision technology specialist Nick Strelczuk.

“An important aspect is that it can import existing geo-referenced data – current and historic yield maps, soils scans, NDVI data, for example – as well as new data such as from scouting or drone scans.” It combines these layers together and decides by how much various agronomic factors should influence inputs, such as seed rate, or applied N. This is based on algorithms, developed by Hutchinsons, using many years’ worth of trials and in-house assessments.

In the on-farm comparisons, each field was split roughly in half, with ordinary farm practice applied to one side and agronomy spatially tweaked on the other, guided by Omnia. “One field near Bourne in S Lincs is a fairly consistent marine clay. We were told it was a field with little variation, but it was obvious from the results that this wasn’t the case,” notes Nick.

A soil texture map of the field, varying from clay loam to clay, formed one layer assessed by Omnia. Seedbed condition and weed pressure were also built in – one corner of the field suffers high blackgrass populations. “Omnia increases the seed rate in areas with bad blackgrass, or you can apply it over the field. It’s based on good, in-house data from Hutchinsons trials, although the variation can be altered.”

Drilled on 5 Oct with KWS Zyatt, the farm standard seed rate was 204kg/ha (392 seeds/m²), applied uniformly, while Omnia produced a seed plan that varied from 189-228kg/ha at an average 206kg/ha (397 seeds/m²). The only other variable was the final N application, based on an NDVI image taken on 21 May. “The same average dressing of 312kg/ha of 34.5%N ammonium nitrate was applied to both sides, with Omnia varying the rate from 265-325kg/ha.”

At harvest, the farm standard part of the field yielded 9.98t/ha, but the Omnia area came in at 10.45t/ha. The cost of production can be overlaid in a layer within the software, which takes account of the inputs applied variably, as well as the resulting yield differences. This varied from £86-173/t across the field, with Omnia averaging £90/t – £9/t lower than the farm standard.

The plans help you decide with your agronomist whether there are areas that need attention or taking out of production altogether.

Nick carried out a geo-spatial statistical analysis of the results, which revealed a significant benefit from using Omnia in all three fields, with an average yield increase of 0.6t/ha. “This is as right and as obvious as it can be. It wasn’t down to field variation – the difference can be attributed to Omnia,” he says.

So with the system, on the face of it, bringing a 20-fold return on investment, is it a hassle to set up and use? Field boundaries must first be imported from crop recording software, such as Gatekeeper, or from the control box of GPS-enabled kit. Data, such as historical yield maps, an electrical conductivity soil scan and NDVI maps can then be brought in. “At the moment, Omnia doesn’t come as standard with satellite-imagery data, although we sell Plant Vision – a boom-mounted biomass scanner that can provide the NDVI layers,” notes Nick.

The datasets are displayed as layers over the field, which can be faded in and out to bring a visual assessment of field variability. In-built algorithms factor in the point data of each layer as an adjustment for the plan being created. “It’s the multi-layer approach that makes Omnia a very powerful tool, compared with some systems that apply an algorithm to just a single layer. You can’t reliably base complex decisions on a single dataset.”

So when creating a seed plan, for example, relevant layers are brought in, such as slug pressure, weed pressure, seedbed condition, topsoil and subsoil scan. Omnia Field Scout allows you to make geo-referenced assessments with a tablet in the field, using a simple three-tier recording system. “Your perception of what’s good and poor may change, and you can adjust that. But the important issue is that you’ve captured the information and are using it as a basis for your sub-field agronomic decisions.”

Once the plan has been created, it can be exported to a USB stick or cloud-based server. This can then be plugged or downloaded straight into an in-cab controller to vary seed rate or fertiliser applications. Omnia now has its own system, Connect, which runs off an iPad, plugged into a small black box in the tractor cab. This in turn runs the in-cab controller, and is compatible with a wide range of machinery.

Yield maps can be displayed as similar, cross-faded layers in Omnia. This allows cost of production to be calculated, using average figures for the inputs applied, or any variable-rate plans created by the software. “There are standard industry costings built in, but you can plug in your own, if you know these.” The resulting plans show unprofitable areas of a field in red, and you can then decide whether these areas need attention or taking out of production altogether.

With over 325,000ha using Omnia, Nick finds the system now forms the basis for new spatial information growers wish to capture. “Once you see the results, it informs where you focus your scouting and monitoring efforts. Once these are captured, they help towards improving the accuracy and value of the results – it’s a virtuous circle of improvement.”

And that doesn’t go just for the business benefits, points out Mike. “If Omnia is as good as it’s proving, the level of accuracy will have considerable environmental benefits, too. That’s a public good that also has value.”

- Omnia Precision Agronomy starts at £250/year for the base package, with the full precision-farming capability costing £5/ha. This comes with OmniaHub, the cloud-based store for all your data. Omnia Field Scout is available free for iOS and Android tablets, while a smartphone version will be available soon. Omnia Connect, including the in-cab black box and wiring, costs £300/year and runs off an iPad equipped with a lightning port (not included).

Cross-platform conversations free up a digital future

In an ideal world, Omnia would automatically populate itself with data retrieved from a whole host of cloud-based sources you’d set it to regularly scour. Your combine manufacturer’s hub would send through ready-to-use yield maps, scouting data would float in wirelessly from your smartphone and third-party sources, and your own crop-recording and financial data would seamlessly synchronise.

Once plans had been made and sent to the cloud, your implements would instinctively set the right rate, varied through the field, without the operator even having to think about it. Perhaps localised climate data, fed through a network of in-field devices and the Internet of Things, would feed in yet more valuable layers to tweak your plans.

This digital-driven Utopia is some way off, with the USB stick still proving to be the linchpin of the system. But Hutchinsons’ precision technology manager Oliver Wood is working hard to help make data-sharing harmony happen.

“The industry realises that data sharing is the way to go – no one will have world domination and the more devices and platforms can talk to each other, the more everyone will benefit,” he says.

Omnia now has an API (application program interface) with MyJohnDeere, the green and yellow manufacturer’s ag web portal, allowing wireless data transfer to GreenStar-enabled equipment. “We’re working with other manufacturers, but a similar API is still some way off. Within the next 24 months, however, we expect most systems to be cloud-based so users can transfer data without having to use a USB stick.”

Data from crop-recording and financial software, such as costings and stocks, have to be manually keyed in at present, while there’s currently no portal or API that allows plans created in Omnia to be transferred back for compliance and record-keeping purposes. “This is largely because the software growers use is built on legacy platforms. It’s an industry-wide problem, and we all recognise it’s our role as providers of these systems to make them as easy to use and as seamless as possible.”

Oliver points out that Omnia itself was “developed from scratch” using the latest data-platform architecture, so doesn’t suffer from these legacy issues. “There is some common language used between systems, and this ensures Omnia can connect with similar cloud-based platforms.”

So what about new digital farming systems, such as FieldView from Climate Corporation, now a subsidiary of Bayer, used across 25 million ha of US crops and about to be introduced across Europe

“FieldView is among a number of new packages coming in. It’s successful in the US because it’s a different market and a different climate. It could have a place in Europe, but I see it fitting in and complementing existing systems, such as Omnia, rather than replacing them,” says Oliver.

Sub-field focus reverses yield drag

Saltby Farms in Leics, farmed by manager Frazer Jolly, hosted one of the on-farm comparisons. Two years of yield maps show the field chosen had tended to yield lower on one side, which contains a clay loam strip running through the predominantly sandy loam soil.

So the challenge for Hutchinsons agronomist Sally Morris was to use Omnia to balance it up. “I started by walking across the field and mapped it with Omnia Field Scout, using soil texture, seedbed condition and slug pressure as three criteria. Fraser and I agreed areas that were poor, acceptable and good. The seedbed assessment was made as close to the time of drilling as possible,” she explains.

This formed the basis for the variable-rate seed plan applied over one side at an average rate of 182kg/ha (364 seeds/m²), drilled with RGT Illustrious on 18 Oct at 164-207kg/ha. The farm standard side was drilled the same day at 178kg/ha (356 seeds/m²).

“More seed was drilled in the clay area, and where slugs were known to be a problem, while the good seedbed through the middle of the field received less,” notes Sally. “As the crop emerged, it looked far from perfect, but plant counts revealed the Omnia side achieved better establishment, and a much tighter range. It looked much better, too.”

The final N application was applied variably on the Omnia side, based on a biomass image taken on 17 May. An average across the field of 404kg/ha of Sulfan (26%N + 35% SO3) was varied from 365-462kg/ha.

“At harvest, the surprising result was that the Omnia side outyielded the farm standard by a staggering 1.4t/ha (8.11t/ha compared with 6.66t/ha) – we’d actually reversed the result from the 2016 harvest.”

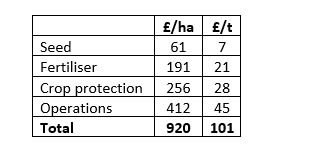

The cost of production map also revealed clear differences – the average across the field was £101/t, but this varied from £76-160/t. The average in the Omnia side was £93/t, but following the farm standard approach cost £121/t.

“Cost of production is a huge focus for the farm business,” comments Frazer. “Our aim was to improve the poorer-yielding areas of the field, and you can see to a clear line the difference here.”

Average cost of production across field at Saltby Farms

Digital Direction

As arable farms progress towards a digital future, it can be difficult to know which forms of data generation, capture and analysis provide a really worthwhile benefit to the business, and which are costly and time-wasting distractions. CPM is working with some of the industry’s leading companies in this area to bring growers some Digital Direction. These articles track the significant steps on the journey towards the data-enabled farm, and also explain and profile the technologies involved.

CPM would like to thank Hutchinsons for sponsoring this Digital Direction article and for providing privileged access to staff and material used to help bring it together.

As a business Hutchinsons continues to invest heavily in all areas of research and development, and precision technology is a key part of agronomy for the future to ensure economic performance and environmental sustainability of agronomy advice.

It is as a result of this approach that Hutchinsons developed Omnia Precision Agronomy.