Involvement in on-farm trials is not only a shared interest for a Suffolk farmer and his agronomist, but it’s helped them both put the future of the business into perspective. CPM pays them a visit.

By Tom Allen-Stevens

Laura Buckingham may be the agronomist for Bocking Hall Home Farm, north of Ipswich, Suffolk, but it’s obvious she has far more involvement in the business than simply crop protection, and it’s a relationship that clearly has benefits for both farmer and adviser.

Ben Styles and his father, David, are tenants of the 200ha mixed arable and beef-suckler farm, part of the Helmingham Estate. Laura’s been their agronomist for the past four years, and now works as arable inputs manager for Fram Farmers.

But she’s also very much part of the team at Bocking Hall. “Ben and I have been friends since primary school, and he’s always been very open about the business – I could come to meetings with the bank manager,” she remarks.

“And I think that’s where agronomy’s going. The role may have been about crop protection in the past, but now it’s a more holistic service, and considers all farm inputs and their costings. There’s also new software and technology that’s becoming an integral part of the agronomy toolbox.”

Cultivations follow an approach that takes good care of the soil.

It’s a career path she always wanted to follow and led her to study agronomy at Aberystwyth University. “I don’t think I’d make a good farmer – I’m not practical enough – but I enjoy being part of the farm business, and I really enjoy the consultative angle of arable production.”

She joined Frontier’s graduate scheme – “they’re a brilliant employer” – and stayed with the firm for eight years before moving to Fram Farmers. At Bocking Hall, one area in which she and Ben share an interest is on-farm trials. “Ben and his dad are thinkers and have a high degree of attention to detail. Running trials adds an extra dimension to the conversation,” she says.

The farm has hosted a number of trials for many years, but these have usually been proprietary trials, with little input from the farmer, notes Ben. “You try to glean as much information as you can – chat to those running it whenever they turn up. But you never see any results.”

So the opportunity to join BASF’s Real Results Circle last year was one they were both keen to seize. “On the face of it, it’s just a fungicide trial. But actually, it makes you question all of your inputs, and makes you look differently at how you can push a field to deliver more and overcome its challenges,” says Laura. (see below).

The main “challenges” across the farm are blackgrass and building biomass into the crop, she says. The blackgrass threat has been increasing for a number of years, and has led to a recent change of tack, explains Ben. “We’d been direct drilling, using a Claydon drill, for around 10 years. We’ve now changed to drilling later and have switched to a Kverneland drill with narrower row spacings to increase crop competition. It also works better on ploughed land, although we still try to establish as little as possible with the plough.”

Ben’s keen to ensure an approach that takes good care of the soil. “We’re looking to put less weight down, and the current drill certainly takes less to pull it. We’re also making more use of manure and other non-bagged inputs.”

Having variably applied P and K for a number of years, the farm has switched back to a field-by-field approach, based on replacing offtake. “Applying variably has its benefits, but I suspect there were situations where lock-up was occurring. Ideally, I‘d like to not buy in any bagged P and K, building organic matter from manure and biosolid applications that we’re rotating around the farm.”

The focus on building crop biomass has come directly from involvement in on-farm trials. Last year, as well as the Real Results trials, they entered a field of oilseed rape into the Yield Enhancement Network (YEN), supported by ADM.

“The theoretical yield potential of the crop is 12t/ha, if everything is spot on,” says Ben. “The information we got back showed we were very much towards the bottom end of that, but there’s a lot we could do differently to improve things and get closer to its potential – I wasn’t expecting that, and it’s quite fascinating.”

Within the trial, Ben and Laura tried a different approach with micronutrients. Manganese and boron are routinely used, but phosphite was added into the programme, applied in Oct and March, with magnesium also added in March. In June, the crop was given a foliar boost of nitrogen, sulphur, Mn, Mg and zinc to optimise pod fill.

The untreated area yielded just over 4.0t/ha, in line with the farm average. But the boosted programme delivered an extra 0.67t/ha – a margin over input costs of £159.62. The programme is now being rolled out across the rest of the farm’s OSR crop.

For Laura, getting involved in these initiatives have benefits that go beyond what’s delivered in the field. “You’re part of a network, and that offers the opportunity to share ideas and learn from others.”

She got the chance earlier this year to join Emerging Leaders, a group of 17 farmers who were supported to attend the Oxford Farming Conference in Jan. Sponsored by BASF, the initiative aims to raise the profile of progressive farmers, use the conference as a platform to place their needs centre stage, and resonate out to others views on agricultural policy and practice.

“We’re all from different backgrounds, but it’s fascinating because we’re all preparing ourselves for a profitable future. What struck me about what we heard from the conference is how thought-provoking it was – some of what was said wasn’t palatable, but the whole industry is facing the challenge of Brexit, and progress will come through embracing change and ensuring your business is resilient,” notes Laura.

“The conference was an amazing place to meet people, too, and those you wouldn’t normally cross paths with. I keep in touch with the Emerging Leaders through a WhatsApp group we’ve set up – rarely a day goes by that there isn’t a discussion about something useful.”

As a tenant on a relatively small farm, Ben feels vulnerable, but equally there are opportunities – the farmed area has expanded gradually, and he gets a premium through his local butcher for the beef. There are niche opportunities on the arable side, too, and Ben and Laura are looking at high-protein E-grade spring wheat, for example.

“Our size worries me, but I’d like to think we’ll be winners,” says Ben. “We’re doing what we can to cut back expenditure, but looking hard at where we can make small gains – I think that’s where we’ll make progress.”

Lessons learned on SDHIs

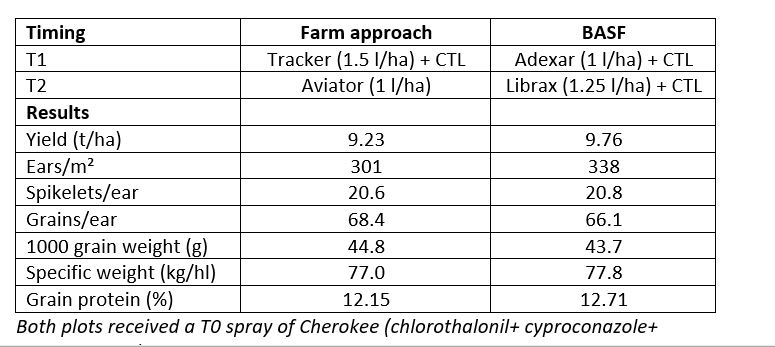

If there’s one aspect the Real Results trials has highlighted, it’s the role of SDHIs, according to Laura. The field chosen for the 2017 trial was Further Woodlands, an 8ha field on sandy clay loam – typical for the farm – and two 24m tramlines were designated as the trial area.

“The field has its challenges and there’s variability, too. This was highlighted in the scans we received from AgSpace, that also showed us the potential for the crop, that we can now compare with what it actually did.”

The dry conditions experienced in April and May and the blackgrass in the field suggested it was going to be a job to build biomass. “So we scaled back on the farm fungicide programme,” recalls Laura.

Rather than have a second-generation SDHI at both the T1 and T2 timings, the decision was taken to use Tracker at T1 (see table). The variety in the trial was KWS Siskin, which strengthened the decision to cut back on SDHI input due to its high disease-resistance scores. “The crop did look under stress from the dry conditions, but there didn’t appear to be any difference between the two blocks in the trial.

“The trial results suggest otherwise, however. These show there was a benefit from using two second-generation SDHIs. It was a conscious decision to scale back, based on cost of production, and you have to consider whether that result would be replicated over a wider area. But I think I’d underestimated the value in terms of the physiological benefits SDHIs bring – they have the potential to build yield as well as just protect it.”

It raises the question of whether it’s right to use one or two second-generation SDHIs within a fungicide programme. “You have to aim for maximum yield with the products available – anything less and you’re not doing your job as an adviser. But you have to be flexible and tailor the programme according to the conditions as they present themselves.

“So I think the main thing is to understand the potential of your crop. I don’t think there’s any harm in using SDHIs to maximise that, as long as you tank-mix them properly and protect them with robust rates of triazole.

“It’s also easy to forget the importance of what goes in the ground in the first place. When choosing varieties, the odd percentage change in yield is meaningless if you pick one that isn’t suited to your situation. We can control disease but shouldn’t stack the odds against us with the varieties we choose.”

Timeliness is also key. “Every year, there’s a drop in sensitivity of septoria pathogens to azoles, and we shouldn’t push this to the limits by putting them in a curative situation. You’re not often wrong if you go a little bit early, but the weather can easily push you too late, and it doesn’t take much of a delay before you’ve lost efficacy. So we aim to be ahead of the problem.”

So what lessons is she taking forward to the 2018 trial? The variety under scrutiny this year is RGT Gravity, in Pecks Field, a 5.19ha piece with slightly heavier soil than last year’s. Across the farm’s wheat portfolio, the variety sits between KWS Siskin and KWS Basset in terms of its disease resistance, she says. “Mildew is its weak link. It’s not quite so strong as some on septoria, but it shouldn’t come unstuck.”

The season will probably start with a T0 application of chlorothalonil plus triazole or Cherokee. The T1 spray is likely to be a second-generation SDHI, with the T2 dependent on conditions, although she feels the trial results have certainly added a different dimension to the decision over whether the farm programme will include two second-generation SDHIs.

“Where we’ll really focus our efforts will be on building and maintaining biomass. We’ve already taken quadrats out and have been counting tiller numbers. I’m wondering whether a four-way split of nitrogen dressings could be a route to building up the crop, and we’ll also look closely at the micronutrient programme.

“The Real Results trial has opened up all sorts of options for us to consider on how to build crop potential, as well as how to protect it,” Laura concludes.

Bocking Hall Real Results trial, 2017

Both plots received a T0 spray of Cherokee (chlorothalonil+ cyproconazole+ propiconazole) and a T3 of prothioconazole plus tebuconazole; Tracker contains boscalid+ epoxiconazole; Adexar contains fluxapyroxad+ epoxiconazole; Aviator contains bixafen+ prothioconazole; Librax contains fluxapyroxad+ metconazole. Although the BASF treatment yielded 0.69t/ha more than the farm approach, this was not quite ‘statistically significant’ so could have been due to other sources of variation, such as soil differences. The yield difference would have to be 0.78t/ha to be deemed statistically significant. The difference in yield between treatments appears to have resulted mainly from more ears/m2, according to ADAS, suggesting the T1 treatment may have slightly improved the tiller survival.