Reintroducing livestock is among a number of changes underway on a Kent farm aimed at reducing reliance on inputs. CPM visits and finds out this doesn’t mean making compromises.

In time, I’d hope we have a system that achieves our yield potential, even on high-performing wheats, with less reliance on chemical inputs.

By Tom Allen-Stevens

There’s something of a shift in direction underway at Pent Farm, Postling, near Folkestone in Kent. Tom Reynolds is farm manager with his uncle for S Salbstein, which comprises a 200ha farm, a maize and grass-silage and arable contracting business. The farm is predominantly arable at present, but Tom’s looking to change the focus.

“We’re building up a beef suckler herd and want it to be more of a mixed farm,” he says. “I feel we’ve gone too far down the route of high input, high output farming. It’s time for a more sustainable approach, and for us the answer is livestock.”

Located on the edge of the Kent Downs AONB, there’s 40ha of the farm that reaches up its chalk scarp slopes, in permanent pasture and extensively grazed. The bulk of the farm sits on heavy gault clay in a rotation consisting mainly of winter wheat, barley and spring linseed, with red fescue and hybrid ryegrass grown for seed.

The bulk of the farm sits on heavy gault clay, which can prove a challenge at certain times of the year.

“We want to grow more grass and apply less inputs,” says Tom. This move is now in progress with 15 suckler cows forming the basis of the new enterprise.

The arable side of the business shares machinery with neighbouring farmers. “The collaboration is becoming more important, with more sharing of skills.”

He’s also moving more towards direct drilling – the machinery he shares includes a 6m Väderstad Seed Hawk and a 6m Horsch Sprinter. These give him options to reduce cultivations on the heavy clay while staying on top of blackgrass. “I’m a big sceptic as to whether rotational ploughing does actually help,” he says.

“The main elements in our strategy are effective use of rotation and good decisions on herbicides. We also use high seed rates to increase competition – 375-400 per m². We aim to drill in the last week of Sept or early Oct – any later tends to be a disaster.”

He’s part of a separate group of local farmers who are trialling different methods aimed at improving soils and finding alternative solutions to agronomic problems, such as blackgrass. A core element of this is investigating the use of cover crops, with a whole variety of different mixes trialled by these forward-thinking farmers, who regularly get together to share their observations.

The mixes Tom has tried have included oats, vetches and oil radish. “We tried sunflowers, which weren’t successful. But buckwheat picks up phosphate, which is useful as our high pH soils tend to lock up nutrients.” He’s also been looking into carbon-based applications that encourage soil biota in a further bid to improve soils and build a more resilient crop.

This emphasis on sustainability has put the spotlight on arable inputs. BASIS-trained, Tom does the agronomy on farm. “We want to spend less, but make the most of the potency of the chemistry we’re using,” he states. That’s what led him to the Real Results Circle.

“Small plot trials don’t tell you enough,” he says. “I’m more interested in doing tramline trials and seeing for myself what the differences are in my own situation.”

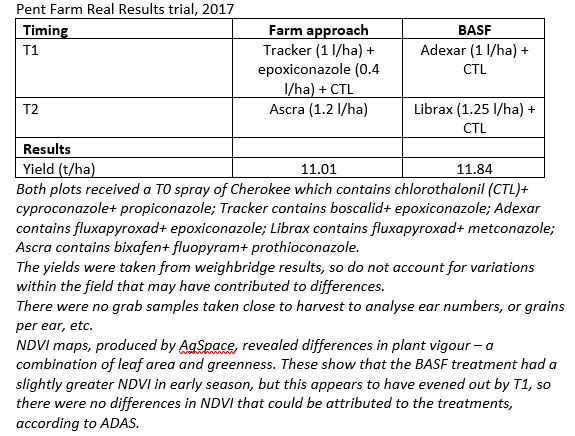

This is the second year of the trials at Pent Farm and the seasons could not be more different, he reports. The Real Results 2018 trial is in a crop of KWS Barrel – a move away from the milling wheats the farm has traditionally grown, into biscuit types. Tom’s aware the variety is more susceptible to septoria – he’s taken a leaf sample sample for DNA analysis, but he’s not going to need the results to tell him the disease is already there.

“Timings went all to cock this year. We couldn’t get on our heavy clays and missed the T0 spray timing completely. Fortunately the T1 was applied on time and across most of the wheat area this was Adexar.”

He’s gone with Tracker at T1 in the farm-standard side of the Real Results trial, however. With the crop now coming up to flag-leaf emergence, septoria is clearly visible on leaves four and five. The upper leaves appear clean, but Tom now knows appearances can be deceptive. “It’ll be interesting to see how the two-SDHI programme compares with just the one.”

This gives him something of a dilemma in his new, more sustainable approach. Having only applied one SDHI in the past, his Real Results and leaf sampling from last year both suggest there are clear benefits from applying two SDHIs, which is arguably a more intensive approach than he currently follows.

Tom disagrees. “Where we’re growing wheat, the sustainable approach is to aim to achieve its yield potential. The Real Results trials are giving us firm answers on how to do this with the fungicide strategy, and we’re now more aware how disease is developing in the crop thanks to the leaf testing.

“While that may lead to a more intensive approach on the wheat, the changes we’re making with cropping, cultivations and particularly bringing in livestock will inevitably mean less inputs are applied across the farm. In time, I’d hope we have a system that achieves our yield potential, even on high-performing wheats, with less reliance on chemical inputs.”

Cura crop brings latent learning

Tom Reynolds was one of a number of Real Results growers who took part in a latent septoria survey undertaken by BASF last year. Like most growers, his crop of RGT Illustrious looked free of disease as it approached T2. Leaf samples were taken and sent off for DNA analysis to see what level of disease infection the crop actually had.

Sure enough, the leaves were infected, which came as a surprise to Tom. “There really wasn’t much disease last year. Adexar is my T2 SDHI of choice, and I was tempted to cut back. The test shows that clearly would have been a mistake.

“So this predictive test is going to be an interesting new way to focus fungicide expenditure. I wouldn’t want to compromise fungicide efficacy but with less actives, the need to keep costs under control and growing public opinion against pesticides in general, having a clearer idea of the actual level of disease you have in the field has got to be the way things should be going.”

Pent Farm Real Results trial, 2017

Come on board for the blackgrass battle

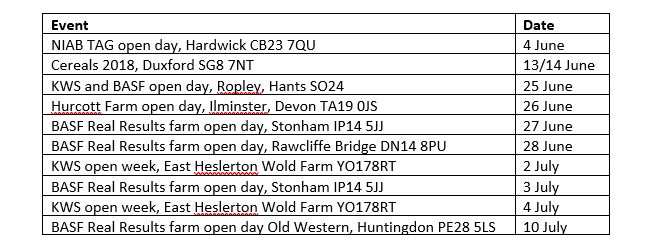

Cereals 2018 will be one of a number of events this summer where growers will have the chance to see the new BASF blackgrass battle bus. It’ll be parked at the entrance to Cereals in the south car park.

What’s more, on the morning of Thurs (14 June) we’ll be running the first CPM Live! Come and take part in this live event at which CPM will be hosting sessions, putting our own questions to the experts and inviting others in the audience to share their experiences. Coffee and breakfast butties will be also be served. If you have a question you’d like to raise, please email tom@cpm-magazine.co.uk. For exact timings of this event, see https://basfrealresults.co.uk/awc/

The blackgrass battle bus is designed to be a dedicated advice centre for growers’ weed control queries and will be travelling across the country this summer, says BASF’s Ruth Stanley.

“We’ve recruited a team of experts to share their thoughts on cultivation techniques, application technology, machinery hygiene, weed biology, and the best chemistry. We know there’s no single element to weed control, but a combination of agronomic choices which growers can make to improve the situation on their farm.”

It’s also a chance to share experiences. “Some of the best ways to control blackgrass come from growers themselves and we’re encouraging them to come and share their top tips. We see the bus as a hub of collective knowledge – the more growers who get involved and share their top tips, the stronger the whole industry will be in our battle against blackgrass.”

Follow the bus timetable shown below to find out when the bus will be at an event near you, so you can hop on board and speak to an expert – at all of the scheduled stops there’ll be at least one expert on board. “We’ll also have leaflets containing advice from the whole team, to give you a full agronomic approach to weed control,” adds Ruth.

“You can watch videos from one of our farmer trials, sign up to the BASF Blackgrass Beaters campaign to receive practical weed control updates through the season, give us your top tips for blackgrass control, or just have a coffee and chat – we’d love to see you.”

Blackgrass Beater team

BASF is searching for the top tips from growers on how to control blackgrass. Those who are happy to share them will be entered into a competition to find the best blackgrass-beating team in the UK. “You and your agronomist can win one of the limited places at our weed control technical conference next year and have the chance to see the blackgrass herbicide of the future,” says Ruth.

Counting the costs

Ever wondered how much cash you’re losing for every hectare affected by blackgrass? Using yield loss figures collected from ADAS over a two-year period, BASF has developed a blackgrass calculator. “This handy tool will give you a reality check on how much your blackgrass populations are costing,” says Ruth.

“Input your estimation of how many blackgrass heads you have per m² in your particular crop, then add in your expected yield and what you’d like to sell that crop for. But beware – the results you get back can be quite scary!”. https://basfrealresults.co.uk/awc/

The Real Results Circle

BASF is partnering with ADAS and AgSpace for the second year of the Real Results Circle. The initiative is focused on working with 50 farmers to conduct field-scale trials on their own farms using their own kit and management systems. The trials are all assessed using ADAS’ Agronōmics tool, which, for the first time, brings statistical certainty to tramline, or field-wide treatment comparisons.

In this series, partnered with CPM, we will follow the journey, thinking and results from farmers involved in the programme. The features will also look at some in-depth related topics, such as SDHI performance and data capture and use.

We want farmers to share their knowledge and conduct on-farm trials. By coming together to face challenges as one, we can find out what really works and shape the future of UK agriculture.

To keep in touch with the progress of these growers and the trials, go to www.basfrealresults.co.uk