A range of new technologies – precise, diverse and data-enabled – are set to bridge the innovation gap as the pesticide toolbox shrinks. CPM glimpsed into the future at a recent showcase at Jealott’s Hill in Berks.

We have technologies that will allow the industry to take a different direction.

By Tom Allen-Stevens

Scientists, farmers and crop specialists may feel they’re sitting in an innovation gap. It could be a thriving UK agriculture that lies on the other side. The question is whether the industry can navigate the right route to get there.

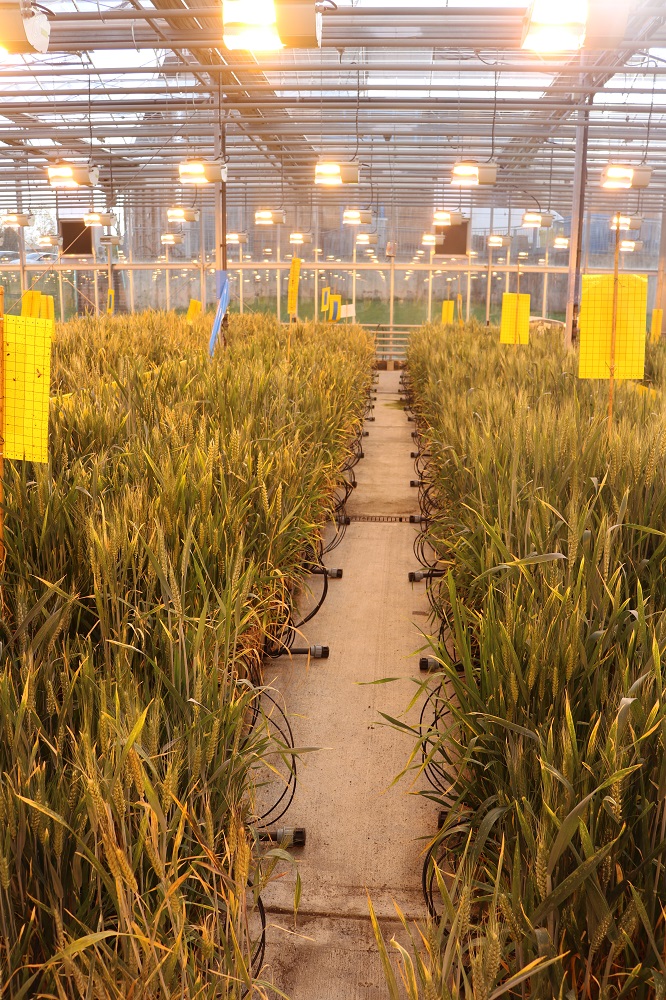

Providing some pointers to suggest the likely direction was a recent Science and Technology Showcase, hosted by Syngenta at the company’s UK R&D site at Jealott’s Hill, Berks. It offered a glimpse of what’s in the pipeline across a range of technologies under development at the site – the global manufacturer’s largest for new agrochemical R&D, employing 850 scientists.

Jealott’s Hill is Syngenta’s largest site for new agrochemical R&D, employing 850 scientists.

“One issue we must be aware of is how we ‘mind the gap’ before these new technologies come to market,” said Gary Mills-Thomas, managing director of Syngenta UK. “Plant-breeding technologies are among those that will help farmers meet the challenges that lie ahead, but the concern for UK growers is that we need the material up and running today to help us grow for tomorrow.”

Political decisions, made with little consideration for their impact, had resulted in a loss of available chemistry, he said. “Historically, farmers have always responded well to challenges set before them. Over the past 40 years, they’ve doubled production, in response to population growth. But now wheat yields have plateaued. How do we continue to push yields forward?”

Growers also produce a plentiful supply of cheap food to a high production standard, he noted. “But we shouldn’t take this for granted – a lot of people still go hungry.”

NFU deputy president Guy Smith sounded a similar note of caution over the importance of the UK’s food self-sufficiency. “I’m not suggesting German U-boats will take control of the English Channel, but we should never be complacent about food security and it would be reckless as a country to be over dependent on imports for our food needs.”

But he sees advances in technology as “really exciting”, offering levels of precision that could dramatically cut pesticide use and satisfy concerns. “Maybe applications for approval in the future will take account of more precise delivery methods, allowing greater leniency on issues such as bystander exposure.”

Niall Mackenzie, director of infrastructure and markets at the Department for Business, Energy and Industrial Strategy, noted that agriculture is an area where the UK has the potential to be “world-beating” as the country’s farmers make good use of new technology. “Society may be putting up barriers, but I see that as an opportunity, not a threat,” he said.

“Syngenta has a good track record of bringing innovation forward,” he added.

Much of this was presented throughout the showcase at Jealott’s Hill. “This is a good place to look forward to new technologies,” said Gary. “The UK has some of the best farmers in the world, and the most productive land. They do a fantastic job to maintain the highest possible standards. We have technologies that will allow the industry to take a different direction. Above all, it’ll become more precise.”

On-target for pesticide precision

“Farmers will always need to manage weeds, disease and crop pests in the most efficient and cost-effective way, but the future of crop protection looks increasingly precise,” said Syngenta application specialist Ben Magri.

Ben’s part of a team at Syngenta looking into precision delivery of pesticides. In cereals, grassweed control is a particular challenge, with herbicide-resistant weeds on the rise, and a tight row spacing making inter-row options difficult, he noted.

Patch-spraying, and for those on wider rows, camera-guided inter-row application or banded pre-emergence sprays are short-term solutions. The team’s looked at applying diquat between rows using a hooded sprayer. “It works, but it’s high risk, as you can easily hit the crop. It would need more work before it could be a commercial reality.”

Precision application in potato crops has real potential for efficiencies, he said. “The first fungicide goes on when there’s only 15% crop cover, so 85% goes to waste. The only reason we spray with a boom sprayer is because it suited delivery of pesticides when they were first used. If we reinvented the sprayer today, it would look very different.”

There’s a real need for a different approach in vegetable crops, with the loss of product approvals leaving a severely limited armoury in some cases, he noted, and a cost of £1200/ha to employ a team to manually hoe out weeds. Syngenta was involved in a Hyperweeding project, funded mainly by Innovate UK, and including research and industry partners, looking into alternative approaches.

“Camera-guided hoes are proving popular, but the soil disturbance encourages more weeds to germinate and disturbs lateral crop roots. Lasers require a lot of power, and the effect on beneficials, such as earthworms, is unknown. There’s also the physical time it takes to burn out a weed – currently a single laser could take 63 days to cover 1ha of lettuce.”

So the project team has looked at a system that passes through the crop, mapping each individual crop and weed plant, and then controlling the weed in real time with a precise-delivery jet of herbicide, explained Syngenta’s Tim Powell.

“This system allows the use of a non-selective herbicide, so here at Jealott’s Hill we’ve looked at what would be suitable and found that the way the product is formulated is very important. With a standard formulation, the high-speed droplets would shatter when they hit the leaf, which could bounce off onto the crop. We’ve devised a formulation that minimised this effect, keeping as much of the spray on the target weed as possible,” reported Tim.

Genome-editing could drive a breeding revolution

Genome-editing could drive a breeding revolution

Unlike plant protection products, the decision you make on a variety is a single point in time, and it’s one that you live with throughout the cropping cycle. That makes it potentially the most important decision about that crop, suggested Syngenta head of trait development Dr Charlie Baxter.

“Globally, the seeds business is worth £40bn. Corn is the biggest market, predominantly driven by GM. But plant-breeding is on the cusp of a data-driven revolution, with advances in our understanding of crop genomes, computing power and gene-editing tools coming together to make the process much more precise.”

A greater understanding of crop genomes means plant breeders can now select traits from a population using genetic markers. Computer modelling can predict the outcome of a cross, allowing the selection of parent material using very specific genotypic and phenotypic data. “That improves the chances of success and increases genetic gain and consequently crop performance,” explained Charlie.

Gene-editing offers huge potential for even greater gains, said Syngenta specialist Dr Kathryn Brocklehurst. This is where the genome is altered by a small change or deletion in a sequence of DNA. It’s a form of mutagenesis that can also happen naturally through stress, or can be induced with a chemical or through radiation, and can result in a phenotypic change that can be useful, such as disease or drought tolerance, or enhanced yield potential. CRISPR-Cas9 is a new technique researchers are currently using where a specific DNA sequence is identified and cut – or edited.

“Gene editing is very precise, with no off-target effects, and we can alter a specific trait. So since we understand the gene mutation that confers mildew resistance in barley, for example, we could introduce resistance into other crops through gene editing,” said Kathryn. It would allow breeders to do so far more quickly – club resistance in brassicas took 20 years to bring in to commercial lines. Gene editing could bring the trait into elite varieties much more rapidly.

Syngenta has been using gene-editing technology for over five years, said Charlie, but all this research currently takes place overseas, since the company made the decision to move seed technology development out of Europe as a result of stringent GMO regulations in the EU. “The UK’s role in this may change after Brexit, depending on the outcome of current negotiations,” he said.

RNA biocontrol to target CSFB

There’s currently a biocontrol in development that will effectively control flea beetle in oilseed rape. It’s an RNA-based substance that’s so specific it selects just a particular member of the flea-beetle complex, so won’t harm beneficials.

That’s the good news. The bad news is it’s still up to 10 years away from commercial use.

It’s a development that’s come about following the acquisition by Syngenta of Devgen, a Belgium-based concern that’s been innovating in this area, noted Syngenta’s Dr Robert Harris. “These strategic alliances between big ag companies and small start-ups will bring the efficacy and reliability to biocontrols that growers expect with the scalability needed for sizable markets.”

This particular new paradigm in pest control is RNA-based, explained Mike Bean, head of Syngenta’s Innovation Centre in Ghent. Messenger RNA is used by cells to instruct the generation of proteins that perform vital functions in the host organism. Introducing a specific RNA sequence disrupts and degrades the target host’s messenger RNA, shutting down the protein generation and killing the pest.

“What’s really exciting is that the RNA is designed to be very precise, so has the potential to control the specific beetles and be harmless to non-target organisms. It’s as close as you can get to the perfect insecticide,” he said.

It’s taken some time to develop the RNA sequences that will interfere with the flea beetle’s targeted messenger RNA. “The science is moving fast, but we’ll also need clarity on regulation before we can bring this to market for farmers.”

Another issue is delivery, noted Jealott’s Hill researcher Dr Rosa Dominguez Espinosa. “As a crop protection agent, RNA is fantastically effective, but easily degrades in the environment. We’re working on a formulation toolbox that will allow it to last long enough to be taken up by the pest.”

CMS hybrid wheat comes into the field

One of the first fields of Syngenta’s hybrid wheat, grown near Chartres in France, came to harvest this year. It’s taken around eight years to get the technology this far, said global hybrid cereals lead Rob Hiles, and the first commercial products in Europe are expected in the early part of the next decade.

“Syngenta started with hybrid barley, mainly because of the barley heritage of the old New Farm Crops programmes. We launched the first Hyvido variety in 2003/4, but didn’t initially fully understand the technical complexities of developing a hybrid cereal crop and what was required to scale it up. However we have learnt a significant amount, which helps lay a great foundation for hybrid wheat.”

The learnings from hybrid barley have facilitated a much more rapid and targeted hybrid wheat development programme. “First of all, you need the diversity of germplasm to develop the right parents, and Syngenta has access to the broadest wheat germplasm in the industry. You also need a viable hybridisation system.”

Successful commercialisation of hybrid wheat has been difficult, Rob explained, because wheat is self-pollinating and hexaploid. To cross pollinate requires a male-sterile parent line, currently achieved through an unreliable and expensive process involving a chemical hybridising agent. Development of the alternative, cytoplasmic male sterility (CMS), is much more difficult, particularly in a plant three times more complex than barley.

“We now have the right system, and with modern breeding technology, such as genetic markers, double-haploid induction and predictive breeding, that weren’t available to us in the early days with barley, this will move on apace.”

There are still challenges – wheat has a relatively heavy pollen, which physically constrains cross-pollination. The robustness of the system needs to be established and an appropriate certification process for blend production adopted. “Hybrid wheat needs a derogation for this to happen, although we have a precedent here with hybrid barley,” noted Rob.

“But we’re now achieving those benefits of hybrid vigour, such as improved rooting, bigger leaves and bolder ears. It was great to see those benefits in the field in Chartres. Whilst that hybrid won’t be the first commercial product, it’s demonstrating progress towards the 10% yield advantage we’re expecting and that we now regularly deliver with Hyvido barley.”

Research Briefing

To help growers get the best out of technology used in the field, manufacturers continue to invest in R&D at every level, from the lab to extensive field trials. CPM Research Briefings provide not only the findings of recent research, but also an insight into the technology, to ensure a full understanding of how to optimise its use.

CPM would like to thank Syngenta for sponsoring this Research Briefing and for providing privileged access to staff and material used to help bring it together.

Syngenta is committed to the continued R&D of both existing technologies and new products to help farmers get the best from every application and make more efficient and sustainable use of resources – to grow more from less. Syngenta invests around £1.1bn a year in global agriculture R&D. These advances enable more effective ICM programmes to create profitable and sustainable farming systems, now and in the future.