The capabilities of spreader technology have soared in recent years, with many new designs being able to push the boundaries when it comes to precision application. CPM takes a look at what’s new on the market.

We’re continuing to make great strides towards improving accuracy.

By Charlotte Cunningham

As with everything in agriculture at present, there’s a huge focus on precision when it comes to fertiliser spreaders.

In the case of fertiliser, this precision is essential not only for improving profitability, but also for minimising the environmental impact these products have.

And this notion has certainly been reflected in spreader design over recent years, with manufacturers making a conscious effort to ensure their product applies fertiliser as accurately as possible.

For 2021, Amazone has further improved spreader accuracy with the introduction of ProfisPro.

Amazone are among the manufacturers making great strides towards improving accuracy – both lateral and longitudinal, says Simon Browne, the firm’s managing director. “With regard to longitudinal, we’ve developed the Profis weigh cell system over the past 20 years which enables any deviations of the actual application rate from the target rate to be accurately identified.

“The weigh cells on the current spreader programme measure the weight changes 200 times/sec and automatically adjusts the shutter positions every 25kg. The biggest advantage of the weighing system is that it measures in real time, and so the application rate is therefore kept at the optimum all the time – even when side, border, water course or wedge-shaped spreading.”

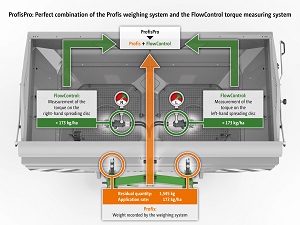

For 2021, Amazone has further improved this accuracy with the introduction of ProfisPro, where the weigh cells work in combination with a torque-measuring disc-load monitoring system. “ProfisPro means that any changes in flow characteristics from either disc are sensed and the aperture size increased to equal up the flow between the left and right discs – although the weigh cell system is what is actually controlling the application rate,” explains Simon.

ProfisPro includes the interaction of the Profis weighing system with the new FlowControl torque measuring system. In this respect, FlowControl is equipped with one sensor per spreading disc, so that the torque on each individual disc can be monitored, he adds. “The correlation between application rates and the torque generated at the spreading disc at different working widths have been determined for all types of fertiliser on the basis of numerous spreading tests.

“Put simply – low application rates generate less torque on the disc than higher rates. FlowControl reliably monitors the torque on each spreading disc drive independently and can immediately adjust the position of the application rate shutters in the event of a deviation from the target rate.”

This combination of weighing system and FlowControl enables the fertiliser spreader to use torque in order to regulate its theoretical application rate over the entire spreading process, explains Simon. “The Profis weighing system monitors the actual spread rate every 25kg. This allows FlowControl to recalibrate itself at regular intervals. This takes place without any need to stop.

“The ProfisPro intelligent weighing system means that the spread rate is optimised from the very first second of the spreading process. In addition, the driver has an overview of the actual quantity remaining in the hopper at all times as well as the possibility to display the remaining travelling distance until empty.”

This new system is available for both the mechanical PTO-drive ZA-TS Profis Tronic and the hydraulically driven ZA-TS (or ZG-TS trailed) Profis Hydro models, he adds.

In terms of the accuracy of lateral distribution, the firm has also tried to simplify set up with the introduction of the mySpreader App. “This rolls the existing EasyCheck tray testing App and the FertiliserService database now into one so that you can find the settings for your fertiliser by brand, granule size, chemical analysis, country etc,” says Simon.

“It’s then possible to verify those settings using the EasyCheck purple mats, whereby you throw out the mats in the field, spread over them and then photograph the number of granules on each mat. The app then tells you how to adjust the spreader – if necessary – to improve the pattern.”

The Amazone Connect system also now allows smartphone connectivity with the spreader, meaning any settings generated from the app can be uploaded into the spreader without the need for manual input.

Amazone’s ArgusTwin system has 14 radars constantly watching the fertiliser leaving the disc and then automatically compensates for any change in spread pattern caused by fertiliser quality, slope of field or operator driving style, says Simon. “When used in conjunction with WindControl, the real time wind speed, strength and direction is given to the spreader which then compensates for the wind effect by changing disc speed or drop point.

“WindControl also has a new anemometer for more sensitivity and reliability which has replaced the existing sensors on the market – and now comes as standard on 2021 spreaders.”

Headland accuracy also continues to be a big talking point and one of the main drivers for some operators switching to liquid fertiliser to get neater “ins and outs” on the headland, believes Simon. “In light of this, Amazone’s AutoTS system gives us more fertiliser and so more yield in that outer few metres, plus the new HeadlandControl improves the ins and outs by swinging the spread pattern round into the field to give more overlap when turning on the ends.

“This coupled with the DynamicSpread 128 section shut-off on the ends means that maximum yield and minimum lodging can be achieved with the TS spreaders.”

Looking at how much more yield can be achieved around the headland is something that Amazone has been researching for quite some time, and as a result, the firm has been able to develop a Border Spreading Calculator. “Amazone developed the border spreading disc in 1980, and even then, the yield potential of the field boundary area was apparent,” says Simon.

Initially, the border spreading system provided an improved lateral distribution of fertiliser from the headland tramline to the field boundary combined with a reduction in the amount of fertiliser spread beyond the field boundary. “Today, the border spreading systems from Amazone are both precise and flexible. For example, operators can not only decide between normal and border spreading without having to stop or climb down from the tractor but can also select the various border spreading options from the cab too.”

The firm has tested its AutoTS border spreading system in trials over several years. “For this we created artificial field boundaries in the centre of fields in large-scale trials, in order to minimise the effect of the margins such as shading, under-fertilisation stretching over several years or competition for water resources from hedgerows and trees,” explains Simon.

“We used the AutoTS system fitted to a ZA-TS and ZG-TS in the trials and compared these with conventional border spreading procedures, in accordance with current practice, and combined the crop from the trial plots.”

The yields from the outermost metre, the outer 3m and the outer 5m of the field were measured and the reference yields of the test fields were also recorded, in order to compare the values.

The yield results showed that there was a significant difference between the various border spreading systems in the trials on the outer 5m of the plots. “Using conventional border spreading procedures, average yields of approximately 68% of the reference yield of the field were obtained in the field boundary area,” says Simon. “In comparison, an average yield of approximately 85% of the reference yield was recorded in the field boundary area with AutoTS.

“As a result, we were able to deduce that the average additional yield with AutoTS is around 17% higher than conventional systems.”

For those looking for a cheap screen in the cab to monitor the GPS functions, but wanting to use the ISOBUS screen to do the spreader settings, then all 2021 spreaders can be linked from the AmaTron 4 control box to a tablet using the downloadable AmaTronTwin App.

If you need something a little bigger, Amazone continues to offer high-performance spreaders such as the ZA-V 2600 ecoSuperior with its high output 6.5kg/sec, spreading up to 28m, points out Simon. “The normal ZA-V can also be fitted with the new EasySet 2 in-cab terminal which does away with the need for tractor hydraulics and operates the shutters and Limiter V+ via push buttons in the cab as well as offering speed-related spread rate control and half-side shut-off. The watercourse, eco or side spreading settings can be saved in the box as well for the Limiter V+ so that the headland spread can be changed on the move for when passing streams and ditches or roads around the headland.

Kuhn

Kuhn is also bringing something new to the market with the launch of the Aero GT 60.1, a trailed pneumatic boom spreader that’s available in 30, 32 and 36m widths.

According to the firm, the Aero GT replaces the AGT 6036 in Kuhn’s current range, with upgrades on its predecessor including a significant 25% increase in the maximum application rate, greater precision in section control, and improvements in the control unit, calibration, and maintenance.

Higher application rates are possible due to increased mass flow characteristics brought about by a bigger air intake and larger capacity pipes. For example, when spreading urea to 36m, application rates of up to 320kg/ha are possible for the Aero GT when travelling at 15kph, compared with 250kg/ha from the AGT.

A new metering system on the Aero GT incorporates six individual units that can be shut off independently when using automatic section control (Kuhn Multirate 6). When used in combination with a variable rate map, each individual unit can also apply a different fertiliser rate.

The possibility of applying a different application rate every 6m across the width of the machine is ideally suited to those farmers who are looking to maximize the control of their inputs, says the firm.

Other refinements include improved kinematics, with calibration claimed to be significantly simpler for the operator. In addition, the fan units are fitted with maintenance-free bearings and the material thickness has been increased on the wearing elements, improving the machine’s durability, and reducing the running costs.

KRM/Bredal

North-Yorks distributor, KRM, are adding to the options for UK growers with Bredal’s new mounted fertiliser spreader – capable of throwing up to 40m – available for delivery from this spring.

The ISBOBUS-ready F4W boasts more accurate section control, with a 12-section set up that can adjust spread independently to either side when working in irregular shaped fields.

What’s unique about the F4W is that the fertiliser is metered by two individual 20cm wide feed belts from the hopper to each disc, explains Mike Britton, managing director. “This positive feed eliminates the need for agitation, which may cause damage to “softer” prilled materials and always ensures the same rate to each disc. A wide range of products can be metered including prilled and granular fertilisers, straights, blends and more difficult materials such as salts, which can’t be handled by conventional gravity-feed machines.

“Consistent application rate is ensured irrespective of changes in humidity, weather conditions, slope or quality of material.”

Looking to the nuts and bolts, two 80cm diameter discs are driven either from the tractor pto through the Bredal twin V-belt drive system, or by an individual hydraulic motor for each disc. The discs spin toward each other to provide a double, double overlap spread pattern with tolerance at working widths from 12m to 40m – dependent on material, while carbide coated vanes give high wear resistance, up to three times longer than stainless steel, adds Mike.

To meet the latest environmental standards for headland spreading, a novel reduction gear system has been fitted to one spinning disc drive. “Operating a single lever reduces the speed of the disc toward the headland by half to produce an adjustable, sharp cut-off at the field boundary, without affecting the spread pattern into the field. If hydraulic driven discs are chosen, then the left or right disc can be selected from the tractor seat for headland spreading.”

The Bredal ISO display also allows the operator to select any application rate, at any spread width and for any material directly from the tractor cab. “It also enables adjustment of rate on the move and provides warning functions for floorbelt drive, disc speed etc,” says Mike.

To give an accurate spread over the total field area, Headland Section Control is standard on the F4W. “This automatically switches on or off the spreading at the correct position when approaching or leaving the headland. In addition, the spread can be adjusted to left or right to match irregular shaped fields or angled headlands.”

Hopper capacity ranges from 1500-4000 litres and standard specification includes weigh cells to monitor the hopper contents – with integral tilt sensor for accurate weight reading even on slopes, giving the operator a continuous display of the actual weight of fertiliser in the hopper.

Also standard is a hopper access ladder and LED rear lighting. “Optional equipment includes hopper extensions, manual or hydraulic opening hopper cover, hydraulically operated headland system and micro-dosing system for slug pellets or cover crops,” adds Mike.

App solutions

A new mobile app from French-firm Sulky is offering growers permanent access to the Fertitest helpdesk from wherever they are – without the need for internet connection.

Sulky’s Fertitest has actually been around for over 15 years, but this new application format means growers can now personalise and change their spreader settings from wherever they are.

The app contains a notepad for operators to create a profile for each fertiliser product used and each adjustment required. Further details can be added to note adjustments needed based on observations in real conditions, which can be accessed each time that product profile is used.

A user can log in to their account to find their previous settings and adjustments, without having to search for each product and configure the machine each time.

The database contains references of more than 1500 granular and solid fertiliser products, with indicative adjustments for each Sulky fertiliser spreader.

If a product is not listed on the database, adjustments for Sulky machines can still be generated by manually inputting the characteristics of the fertiliser. This functionality is also available in disconnect mode, without the need for mobile internet.

The new Fertitest app is available through Apple’s App Store, or Android’s Google Play store, and continues to be accessible on desktop, too.