With a year of unprecedented uncertainty ahead, it’s worth putting the finances in order before making large purchases. CPM seeks expert advice (and rounds up a few more enticing novelties).

A key element is to make sure that the farm does not spend too much on machinery – UK agriculture remains profligate in this area.

By Tom Allen-Stevens

Yes – it’s a very nice piece of gleaming kit, but how do you pay for it? That was the rather sobering question farm business consultant Andersons was asking farmers to ask themselves at LAMMA 2019.

Away from the glitz and glamour of the main machinery halls at the NEC, the focus was turned to getting businesses Brexit-ready and pointing purchasing policies in a realistic direction.

“Brexit is actually a slightly marginal issue,” notes Andersons’ Sebastian Graff-Baker. “The economic cake of food production is only so big, and there’s still a substantial amount of inefficiency on many farms to address. You can make the change tomorrow – getting too involved in Brexit is shying away from the issue.”

He advocates farmers spend time looking at the internal factors that affect the efficiency of the business. Andersons was commissioned by AHDB to look at the features of top-performing farms and eight recurring themes emerged, notes Sebastian:

- Have a clear business strategy, shared with partners

- Set goals and budgets with timelines and values

- Compare yourself with others, not just in your sector, and gather information

- Minimise overhead costs

- Know who your market is, listen to them and meet their requirements

- Focus on the details that matter but retain a view of the big picture

- Have a mindset for change and innovation

- Remain disciplined and stick to your strategy.

The eight points are designed to be broad-brush, and each individual farm should consider how they relate to their business and how they can be translated into specific management actions, he notes.

“One of the strongest influences on business profitability is overhead cost control. The top performers in all sectors have lower overheads than the rest. A key element is to make sure that the farm does not spend too much on machinery – UK agriculture remains profligate in this area.”

The first step might be to compare performance with other similar farms. “There’s plenty of good ‘benchmarking’ information available in UK agriculture, and this doesn’t have to be in terms of £s – other measures such as horsepower per ha can be looked at. This exercise will highlight any areas where there’s room for improvement. The next stage is then to look at the options for addressing these issues.”

Sebastian reckons the big win in terms of reducing overheads often lies in cutting machinery depreciation costs, and that simply means owning less high-cost equipment. “Sometimes, the farming system is fundamentally wrong with too much horsepower being deployed growing the wrong crops in the wrong places. In other cases, a more open-minded approach to how machinery resources are obtained is required, such as hiring, contractors and sharing.”

The top-performing farmers are also finally making good use of precision farming tools, he continues. “It’s about measuring yield and understanding variation is absolutely key.

“If you produce a greater yield per ha, you will be more efficient. But the 5-7t/ha areas are being subsidised by the 7-10t/ha areas. So a wise move could be to produce 80% of your current output by dropping 40% of the land you farm. It’s counter-intuitive and it makes machinery purchasing harder, but it’s a cost you can control and you can match it to the size of your business to ensure it’s truly profitable,” says Sebastian.

On the policy side, there’s still a lot of uncertainty, notes colleague Richard King. “The coming year promises to be a watershed for UK agriculture – there are scenarios of very good to very bad and everything’s on the table.

“But domestic policy and future support are becoming clearer. The Secretary of State has set out his plans for England that sees support remain as it is for 2019 and 2020. The Basic Payment will then phase out and will be replaced with Environmental Land Management (ELM) contracts.”

Richard points out some fundamental differences to prepare for. “BPS was all profit, but it’s likely that’s not how ELMs will work. What’s more, it’s unlikely farming will receive its current funding of £3.2bn – I’d say we’re looking at a 50-60% cut.”

The winners will be those with land attractive to public goods, he reckons – those on a flood plain, with public access or agroforestry will do well, he suggests. Grass-based intensive farms, such as dairy enterprises may lose out. “The fundamental problem is that high-fertility systems don’t fit well in environmental schemes, although it’s still unclear exactly what public goods the government will favour.”

With change also comes opportunity, but the focus during the next 12 months must remain on improving the efficiency of the farming industry, Richard emphasises. “The UK farming sector has had a couple of years of good profitability. The temptation may be to use this money to ‘kit up’ to see the business through tougher times that may be ahead. However, any investment needs to be justified on its own terms.”

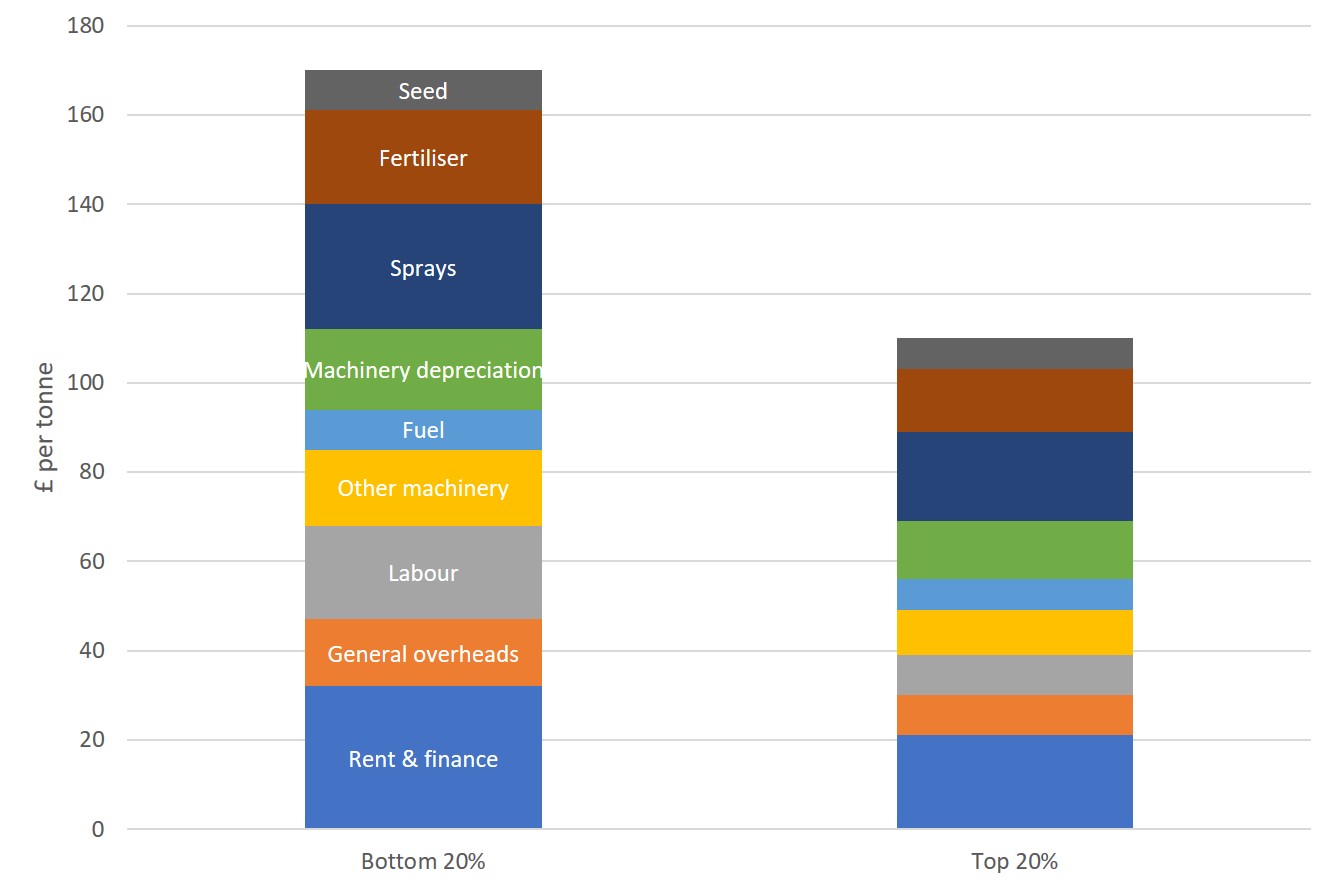

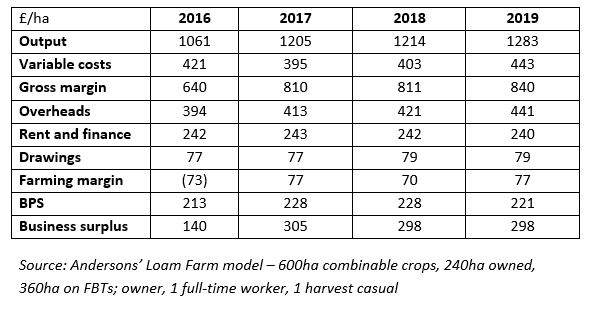

Cost of production – feed wheat

Source: Andersons’ Loam Farm figures for 2018 adjusted for performance differentials seen in the Farm Business Survey

Costs of production – where do you sit?

Good reception for farm-proof phone

Not only is it shock, water and dustproof, this new phone from Caterpillar features thermal imaging capability, laser-assisted distance measuring and an indoor air quality monitor.

The Cat S61 rugged smartphone sits at the top of the range, specifically designed to withstand on-farm rigours. The four models available are built to survive being dropped on concrete or in a wet and muddy field, to handle the dusty conditions of harvest or withstand a power hose-down, with no ill effects, and can be controlled with wet hands or while wearing gloves.

The S61 has completed a year’s pilot with farmers and growers who report using the inbuilt thermal imaging technology for tasks such as locating hot spots in grain stores, confirming mastitis in dairy cattle, checking for hypothermia in lambs, and on-farm fault-finding such as draughts in sheds, or faulty machinery wiring and radiator leaks or blockages.

It has an extended (12+ hours) battery life, a 5.2in display, 16MP rear camera with LED flash, and packs a punch with its Snapdragon Octa-core processor, 64GB of ROM (expandable) and 4GB of RAM. It’s available open, unlocked, takes dual SIMs, and is priced at £799 from Reading-based Bullitt Group, the global mobile licensee for Caterpillar.

Making sense of remote grain store control

Launched at LAMMA 2019, the new Robydome WTM-1 smart grain store monitoring and control point brings complete remote management of temperatures and ventilation within the crop in flat-floor stores, to your smartphone or tablet.

The WTM-1 is a self-contained smart box in the store, linked to its temperature probes and ventilation system sensors. All the information to manage store conditions is available instantly, and in real-time, using a clear and simple web-browser page to check and make changes.

Linked to ambient humidity and temperature sensors, it can autonomously regulate if and when fans operate, to condition the crop to the desired storage point.

Hot spots can be quickly targeted and resolved – the WTM-1 will automatically send an email alert if any danger points or problems are triggered. Records continuously track progress and reports as grain temperatures cool. With the Robydome system all the store’s historical records and data are held on the farm’s own box, rather than a remote server.

A single WTM-1 control point can manage up to eight stores, with up to 32 sensors in each store. It’s fully compatible with the company’s range of wireless probes and sensors for new store installation or upgrades, as well as a retro-fit for suitable existing Robydome systems.

JCB Launches New Series III Loadall

A new range of agricultural JCB Loadall telescopic handlers has been launched featuring increased lift, improved safety and a brand-new Command Plus cab.

The new cab has spent five years in development – the product of 50,000 man hours and an investment by the Uttoxeter-based manufacturer of £8M. It is roomier, with 12% more volume, has a neater control layout and provides 60% more dedicated storage space. Visibility to the front wheels and beyond has been improved by 14% by the low-set dash panel and upwards to a raised bucket or fork by uninterrupted glazing that sweeps up and over the operator’s head. It’s also 50% quieter, boasting a best-in-class noise level of just 69db.

The new Series III JCB Loadall range comprises four models with up to 200kg increased load capacity over their predecessors – the 6m lift 538-60, 7m 532-70 and 542-70, and the 9.5m high-lift 536-95. The heavy-lift, bulk handling 560-80 with 8m lift height and 6t lift capacity remain the same, and the 536-70 LP continues unchanged with its existing low profile cab for poultry shed and other low height applications.

There’ll be a full report on the new JCB Loadall in the March issue of CPM.

Cut through the crop for conservation ag

He-Va showcased its new Top-Cutter knife roller at LAMMA 2019. Designed to assist in cover crop destruction, the Top-Cutter can be fitted as an option to He-Va front presses, rolls and Disc-Rollers.

Mounted ahead of the main cultivation elements, the roller has six double-sided blades which span its full working width and provide a transverse chopping action. The press or pakker rings on the host machine work at right angles to the knife roller ensuring crop residues are comprehensively dealt with.

The roller is mounted to the main toolbar frame via the same rubber torsion damping system used on He-Va’s disc cultivators.

The Top-Cutter helps those farmers moving towards conservation agriculture, says Opico’s James Woolway. “We’re developing new and improved mechanical ways to break down and incorporate cover crops and green manures so that farmers can include green cover in their rotations without heavy reliance on chemicals for incorporation.”

Available as an option on He-Va Front-Rollers and Front-Pakkers up to 6m wide as well as Disc-Rollers from 2.5m to 6.5m and the 12.3m Tip-Roller XL, the Top-Cutter can also be retro-fitted to certain existing machines. Prices start from £4,652 RRP.

First UK showing of Mirco Plough

Maschio has followed up its entry into the UK plough market last summer with a new bigger and ‘beefed up’ semi-mounted Mirco plough.

Expected to be on sale in the UK this autumn, the new plough is based on a larger 160 x 160mm main beam frame and has the option for in-furrow or on land/in-furrow ploughing.

Requiring pulling power of 230- 400hp, there’s an interbody clearance of 105cm. The plough will be available in 6-9 furrows in a shearbolt version and 6-8 furrows in the non-stop hydraulic (NSH) version. Its rear wheel is in constant contact with the ground which, alongside a pivoting headstock design, gives the plough a tight headland turning angle of over 100°.

Farmers fund new robotics concept

British farming robotics start-up the Small Robot Company has brought on board hundreds of farmer investors in its latest round of fund-raising to develop its Tom, Dick and Harry autonomous farming robots.

The Crowdcube campaign, launched in Dec, smashed its initial target of £500,000 within minutes of launch, thanks to support from farmers, who collectively contributed several hundred thousand pounds. The campaign alone raised £1.2M, bringing the total funding for the project to £2.5 million since its launch at the Oxford Farming Conference just a year ago.

Small Robot Company uses the power and precision of robots and Artificial Intelligence (AI) to seek to improve the way food is produced and minimise chemical usage. Instead of tractors, farmbots Tom, Dick and Harry will monitor, plant, feed and weed arable crops autonomously, precisely with minimal waste.

The company’s small team of scientists and engineers are working in conjunction with a group of trial farmers to develop the technology from early proof of concept prototype to a more robust working model. Prototype Toms have been scouting crops, reporting back to Wilma, the AI brain of the system, who can now tell wheat from a weed. Harry, the digital planting robot prototype, was showcased at CropTec.

SRC is now looking to establish its ‘Hundred Club’ panel of an additional 100 farmers, both for regular consultation and to come on board to trial its robotics service when it is ready for large scale commercial trials in 2021.