A new company has launched with a revolutionary new concept that could totally transform the way crops are farmed. CPM reports.

We know that 95% of herbicides can be saved using a smart sprayer and small robots can help to make this technology work at scale.

By Tom Allen-Stevens

Welcome to a completely new way to farm. It’s one that doesn’t tie up farm staff passing endlessly up and down fields, in fact you won’t even need a tractor. There’s a new team who’ll do all the work – Tom, Dick, Harry and Wilma. The big difference here is that they are robots.

This may sound like the stuff of science fiction, but it’s been passing through various research projects for years, and a number of prominent scientists and visionaries have introduced the concept at farming conferences and symposiums.

Then in Nov last year, the Small Robot Company launched. This British agritech start-up has been developing a system of farming that “harnesses the power and precision of robots and artificial intelligence (AI) to improve the way that food is produced and minimise chemical usage”.

The claimed benefits are bold – 95% less chemicals, 40% revenue increase and 90% reduction in cultivation energy by using robots not tractors. These were put forward, along with progress to date, at a fringe event of the Oxford Farming Conference last month.

“Current farming practices are not sustainable, not in terms of productivity, nor profitability, and certainly not environmentally,” says Sam Watson-Jones, co-founder and fourth generation Shrops farmer. “Farming, and in particular farm management, needs to become a fully digitised process.”

So how? “We’ve been developing a system which allows the farmers to take a cereal crop from planting through to harvest without the need to take a manned tractor or sprayer onto the field.”

Instead, you use a team of robots:

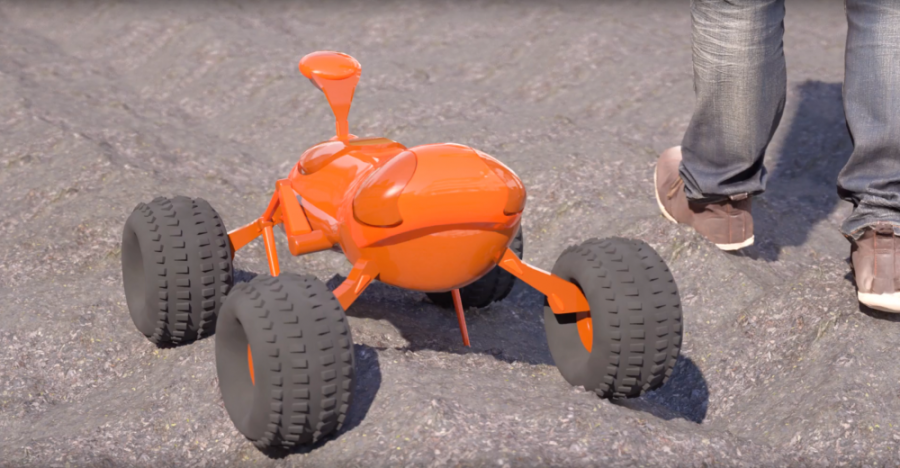

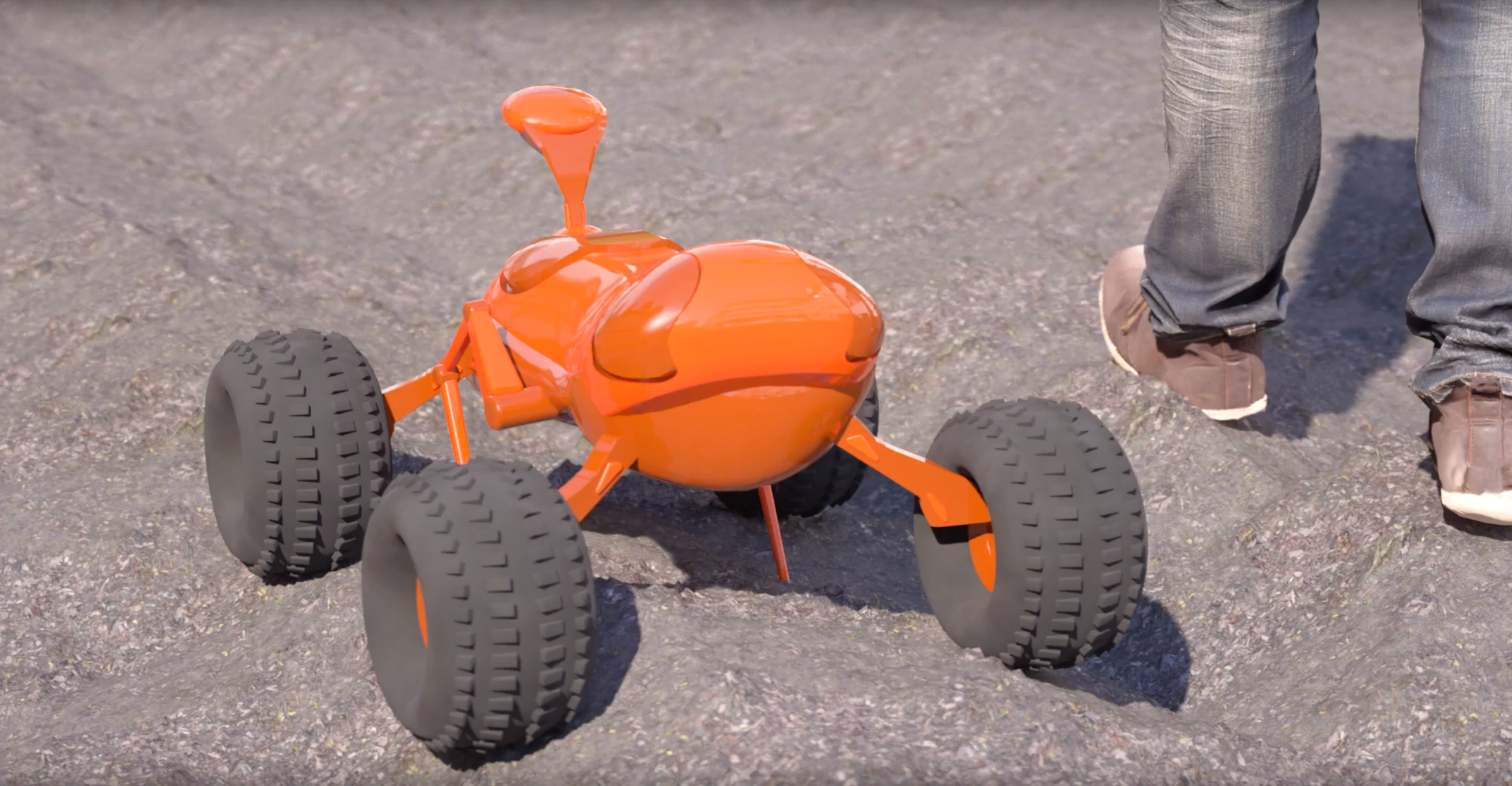

- Tom, a crop and soil monitoring robot. A prototype version, about the size of a large radio-controlled car, has already been built and “he” (note the in-house terminology, elevating the robots above mere machines) is currently going through training on Sam’s farm

- Dick, precision spraying and laser-weeding robot, currently under development

- Harry, precision-drilling and planting robot, also being developed

- Wilma, the operating system and the computing power behind the AI-driven neural network. She has the brains and churns the algorithms that enable the system to learn as it covers more ha.

“Our robots are not for sale, but are instead leased out to farmers on a per ha basis through a model called Farming as a Service (FaaS),” continues Sam.

And this is the other novel part of it. FaaS is both a hardware and a software service for farmers. You pay a per ha subscription fee for the robotic team which digitises the farm, and then delivers crop care at per-plant precision.

The robots take care of all the feeding, seeding, and weeding. When one of these robots is needed, he turns up and does his job. When he’s done, he’s taken away. “This makes it very low risk for farmers to trial and adopt. It also means that farmers no longer have to worry about buying, storing or maintenance of most crop care machinery and equipment.”

The technology itself is built on 15 years of research by Prof Simon Blackmore, head of agricultural robotics at Harper Adams university, who’s mentoring the company. His vision is that many of the jobs currently done by tractors in fields can be done at a lower cost, more accurately and with less waste by small robots.

“Currently, 90% of cultivation energy is used for ploughing, which is only necessary because of heavy machinery crushing the soil, and if you treat the whole field the same, overuse of chemicals is inevitable,” he says.

“We know that 95% of herbicides can be saved using a smart sprayer and small robots can help to make this technology work at scale.”

Robots are smaller, lighter and more precise than the current farming systems using tractors, he explains. “Using small robots instead of tractors will deliver greater yield from less inputs. They can also work in smaller and more unusually shaped fields, making the most of headlands while protecting hedgerows, biodiversity and the British landscape. Longer term, it radically improves farming methods and food potential.”

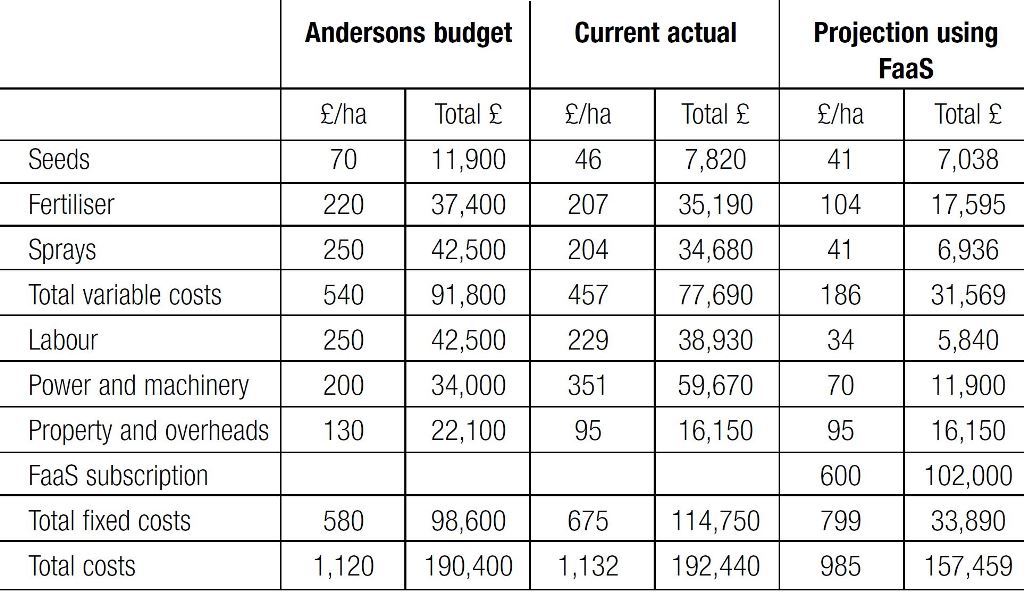

Using robots has the claimed potential to reduce chemical usage in arable farming by as much as 95%, and reduce cultivation energy and associated carbon dioxide emissions by 90%. According to projections prepared by the Small Robot Company and verified by Andersons, FaaS can increase arable farming revenues by up to 40% and reduce production costs by up to 60%.

Much of 2017 was spent developing the concept, the hardware and software. The company has also surveyed over 100 farmers to gather practical information on how the technology is best applied – it’s keen to stress this is a system is developed by farmers, for farmers.

Along with Sam, the human team includes robotics expert Joe Allnutt and co-founder and entrepreneur Ben Scott-Robinson. “What we’ve done is to take this idea, work with farmers to understand how it can answer their needs, and make this into reality,” says Ben.

With prototype Tom already undergoing training, trundling over wheat crops on Sam’s Shrops farm, the data he sends to Wilma is currently building what Sam says will be the world’s most detailed living data model. Through machine-learning algorithms, Wilma’s brain, or neural network, will develop and this can be used to hone agronomy on wheat crops across the country.

“We’re planning to take Tom on tour this spring,” says Sam. “We’re looking for different sites across the UK so he can develop his and Wilma’s understanding of the wheat crop and what weeds, pathogens and cropping issues they’re likely to need to evaluate.” Dick and Harry, currently being built, will be somewhat larger than their team mate, and the company already has its first paying customers signed up to use the services.

“Technology has changed almost every industry, but farming is still stuck on analogue. We want to digitise the field, and the potential for efficiency here is phenomenal,” continues Sam.

“As many as 85% of UK farms are currently reliant on subsidies. But with digitisation we will see a big increase in the number of small farms which are independently viable without subsidy. This is great news both for those long-standing family businesses, but also exciting for the development of the rural economy.”

- The Small Robot Company is looking for more views from farmers on how the technology can be applied, as well as testing sites for Tom.

How Farming as a service (FaaS) works

You don’t actually buy the kit, but subscribe to the service. Tom is placed in a kennel on your farm and trundles about constantly checking the crop. He passes information back to Wilma who decides on instructions for Dick and Harry.

When appropriate, Harry is called in to plant the crop (without ploughing), and record the location of every plant. Depending on what Tom finds, Dick is sent out to feed the crop, zap the weeds and spray the nasties.

With no expensive field machinery sitting around for 11 months of the year, there’s less capital outlay and farm staff can focus on other business activities rather than repetitive field work, says Sam. The figures assume your crops will be healthier, your soil in better condition and your yields higher. Bills for fuel and chemicals will be a fraction of what they were.

Figures based on actual or projected costs for 485ha Howle Manor Farm, Shrops (Sam’s farm), verified by Andersons.