Smart farming technology has been fundamental in driving increased efficiency and precision on farm. CPM takes a look at the hottest innovation.

The opportunity is immense

By Charlotte Cunningham and Tom Allen-Stevens

Whether you’re never without the latest app, or a self-confessed technophobe, there’s no denying that the influx of smart farming technology over recent years is revolutionising the way we do things.

Not only does this kind of tech mean important information is usually always at the fingertips of growers, but the complex analytical capabilities also enable precise, efficient on-farm operations.

With innovation coming through at a rate of knots, it’s easy to lose track of the latest launches. So to help growers get a feel for what’s new, CPM highlights some of the most interesting tech on the market.

Small Robot Company

The Small Robot Company has been leading the way in robotics and automation for a few years now and the firm’s latest announcement indicates its looking to delve even further into the world of smart technology with a 5G-ready agri-robot.

The 5GRuralDorset project is a collaboration between SRC, Wessex Internet, Telint and Dorset Council, which aims to develop and prove a blueprint for rural-optimised 5G connectivity, in a bid to overcome the ongoing challenge of poor rural internet.

According to SRC, the resulting 5G blueprint will enable rapid deployment of 5G to rural areas. It reckons that this has the potential to dramatically close the rural/urban digital divide for farming and rural communities – stating that it could be game-changing for boosting rural investment, creating skilled jobs and improving prosperity.

The £7m project is being part-funded by the Department for Digital, Media, Culture and Sport as part of its 5G Testbeds and Trials Programme.

The 5G robotics trial aims to demonstrate a revolution in farming, increasing productivity, yields and biodiversity while simultaneously reducing environmental impact. Importantly, it also looks to improve soil health and reduce emissions, helping farmers meet the UK agriculture target of Net Zero by 2040.

Alongside the work with SRC, Wessex Internet is working with other industry players to trial uses of 5G connectivity in agriculture. The aim is to deliver novel high/mid bandwidth 5G solutions and innovation within agriculture.

“This 5G blueprint could be a catalyst for rural economies – with our robots demonstrating the potential for 5G to transform agricultural productivity,” says Ben Scott-Robinson, CEO and co-founder of Small Robot Company. “Connectivity is not a luxury. It’s a utility. And vital to economic performance.

Ben believes that 5G technological development within agriculture is vital post-Brexit. “One of the biggest obstacles facing UK farmers in adopting new technologies is poor connectivity around the farm. This 5G blueprint will pave the way for growth in the rural economy – and alongside it greatly-improved quality of life.”

In terms of how exactly the project will work, Wessex Internet will be delivering three farm 5G networks on the back of its existing 2100km full-fibre network as part of the 5G RuralDorset trials.

As a company with a farming background, the rural connectivity provider will be aiming to experiment with a 5G network which is fit for the industry – testing the technical and commercial viability of 5G deployment models in rural areas. The trials with the SRC robots will be taking place at the Ranston Farm 5G trial site.

SRC is building a 5G-enabled Tom monitoring robot, Kennel and Robot Handler App. In addition, the project scope includes a 5G-enabled Dick non-chemical weeding robot. SRC will test this capability in Dorset from Oct 2021 to Mar 2022, writing a report on the resulting outcomes and benefits for its Farming-as-a-Service robotics model.

“The opportunity is immense,” adds Sam Watson-Jones, SRC co-founder. “Our technology is closely aligned with the new Agricultural Bill, at the heart of these systemic changes in farming. The 5G RuralDorset Project is an opportunity for us to work with farmers to create a more sustainable and productive farming model. The recent huge advances in ag-tech finally make this possible: and farmers are integral to the environmental solution.”

KisanHub

Digital software provider, KisanHub, has launched a new Paperless Load Passports feature – designed to change how products move through the fresh produce supply chain and allow users to manage the process from their mobile devices.

According to KisanHub, the new feature saves time and minimises errors with the added bonus of traceability from the farm to the factory gate.

“We believe the world’s food supply must become sustainable,” says Giles Barker co-founder at KisanHub. “Our new Paperless Load Passports are an easy, simple and dare we say fun way to make a significant positive difference in our industry.

“Almost everyone on this planet has a mobile phone and we’ve embraced this fact, by making data collecting and sharing easy, even enjoyable. We’re very excited about the impact this low-cost tool can bring to one of the oldest industries in the world.”

The new Paperless Load Passports feature is available now and existing KisanHub customers can use this feature free of charge at their current tonnage contract.

BASF Digital Farming

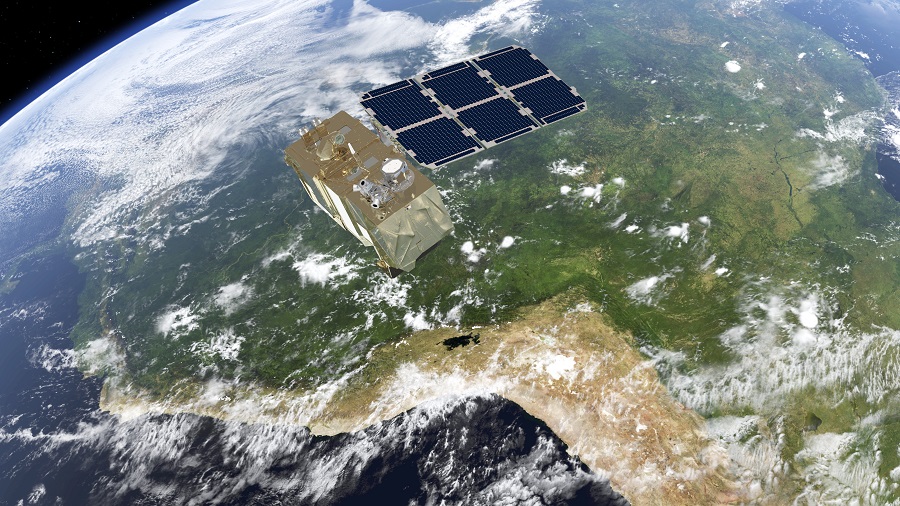

As well as innovation on the ground, there’s plenty happening in the skies and a new collaboration between BASF Digital Farming and VanderSat is set to be the first entity to globally offer access to scalable, daily biomass images, unimpeded by cloud cover.

The two companies have signed a commercial agreement, which will see the integration of VanderSat’s innovative, fully operational ‘Cloud-free Biomass’ product with BASF Digital Farming’s xarvio Field Manager solution.

According to BASF, farmers will get daily access to high quality, consistent, cloud-free biomass images. “Faster access to biomass images enables consistent monitoring of crop growth and leads to enhanced agronomic decisions. This optimises crop production, saves time and money, and fosters sustainability in agriculture,” says the company.

Cloud-free Biomass is the result of collaboration and testing by xarvio and VanderSat teams over the past two years. The new product was successfully tested in Germany, Ukraine, United Kingdom, Canada and Brazil during the 2019/20 growing season.

According to BASF, it has a high spatial resolution (10m x 10m) and provides a single, consistent metric of crop biomass. This allows farmers to compare the performance of several fields over a large area, or in different growing seasons.

Integrating three different satellite products together, Cloud-free Biomass uses VanderSat’s retrieval method for passive microwave technology, along with active microwave from the European Space Agency’s (ESA) Sentinel-1 satellite and optical images from its Sentinel-2 satellite.

VanderSat then uses its expertise in remote sensing to interpret the output from these data sources to provide a reliable, daily measure of crop biomass.

In some parts of Europe, North and Latin America biomass images are significantly obstructed by cloud cover. At times it can take more than two weeks to receive a ‘clean’ biomass image, which by then is usually outdated because crop conditions have changed, says BASF.

By contrast, Cloud-free Biomass images are available daily and offer additional benefits. Unlike Normalised Difference Vegetation Index (NDVI) biomass images from satellites, also not available on cloudy days and which only measure spectral greenness, Cloud-free Biomass measures biophysical parameters and water content in vegetation to continually and accurately calculate all stages of crop growth during the entire growing season.

“Giving farmers quicker access to reliable, quality biomass images provides greater oversight and helps to reduce risk, by ensuring any required action can be taken almost immediately,” says Jeff Spencer, xarvio global technology and data lead. “We are confident Cloud-free Biomass will be well-received by xarvio Field Manager customers and the agricultural industry.”

Cloud-free Biomass is expected to be integrated into xarvio Field Manager by the end of Mar 2021 and will be available in North America and Latin America.

Other regions will follow during the year.

UPL

Another collaboration worth noting is that between UPL and TeleSense technology.

According to UPL, the aim of this is to work towards solutions that reduce food waste, while enabling on-farm resilience.

In terms of how this might look practically, the focus is going to be specifically on grain storage, handling and transportation, in a bid to create a more data-driven supply chain.

TeleSense uses scalable sensor technology on an artificial intelligence platform to monitor the temperature, humidity and CO2 levels of stored grain.

It leverages fixed and portable sensors to monitor the current and future condition of stored grain, while automating the detection and mitigation of potential issues such as hotspots, excess moisture, or pests.

Machine learning algorithms provide users with alerts needed to effectively manage and predict grain quality, ensure safety, improve operational efficiency, and increase profitability, says UPL.

Tried and tested efficiency

Now well established across the company’s combine range, recent testing conducted by the German Agricultural Society has shown that Claas’ recently introduced CEMOS for tractors system has the potential to increase efficiency by up to 21%.

CEMOS has been coined as an onboard virtual advisor, suggesting values and settings to optimise performance and in turn reducing issues such as tyre wear, operating costs and soil compaction.

Testing was carried out last Sept. Using mounted cultivators, the operators shallow- and deep-cultivated the strips of slightly and very loamy sand on the test plots over a three-day period – directly comparing performance with and without CEMOS activated.

The results showed that with the CEMOS system activated, it was possible to reduce diesel consumption by up to 16.8% and, at the same time, increase the area output by up to 16.3% for 80% of the operators.

Based on this and looking at fuel consumption figures over 3000 operating hours of tillage, a large tractor with a diesel consumption rate of 41.6 litres/hr (with CEMOS) could save up to 25,200 litres of diesel and 67,000kg CO₂ annually, reckons Claas.

In addition, by increasingly area output, the hours worked by the farmer or contractor are reduced by up to 490 – the equivalent of almost 50 working days.

Lemken has also received recognition for its iQblue connect system, following conformity testing carried out by the independent Agricultural Industry Electronics Foundation.

The smart iQblue connect retrofitting kit, which was also awarded a silver medal at Agritechnica 2019, offers the operators the opportunity to use the benefits of Tractor Implement Management (TIM) control for smart tillage, says Lemken.

Combined with the ISOBUS interface on the tractor, iQblue connect allows data to be exchanged between the tractor and implement. As a result, the implement is able to control certain tractor functions automatically, for example the ground speed or spool valves.

This retrofitting solution allows existing tillage implements to be automated and a single iQblue connect module can be used with a range of implements.

The module is connected to the tractor via its ISOBUS interface. It also features GPS and a mobile data connection for communication, for example with a farm management system. The system automatically adapts to the implement it is connected to at any time and therefore substantially reduces the user’s workload.

For ploughs, Lemken offers GPS-based working width control as a first step. Here, iQblue connect transmits implement data on the plough’s GPS position and current working width to the TIM to enable the hydraulic control unit on the tractor to automatically control the cylinder for the plough’s working width. This ensures that the plough always produces a precise and straight furrow.

At the same time, it also allows operators to plough towards a target furrow, increasing the efficiency when ploughing wedge-shaped fields.

On semi-mounted cultivators, the working depth can be detected by a sensor. In this case, iQblue connect collects the area-specific target working depth from digital maps, and the TIM adjusts the working depth of the tine section and levelling tools to the changing soil conditions in the field via the tractor’s hydraulic system.

iQblue connect is compatible with implements by other manufacturers and will be available from Oct 2021.

Grant funding for innovation

UKRI and Defra have recently announced a research and development collaboration for a new funding opportunity, aptly named: Farming Innovation Pathways.

The competition will be delivered through UKRI’s Industrial Strategy Challenge Fund (ISCF) Transforming Food Production, aimed at developing new and existing farm-focused innovations.

UKRI has said it’s keen to ensure Farming Innovation Pathways translates leading research in agriculture into practical guidance to directly benefit farmers and support them to address the challenges of productivity, sustainability, and net zero emissions in UK farming.

The first competition of its kind following the UK’s departure from the EU, it will pave the way for R&D to “turbocharge” future innovation in the agricultural sector, said the non-departmental public body, responsible for the government’s £8bn annual R&D budget.

Farming Innovation Pathways will act as a bridge between the final stages of the Transforming Food Production programme and the launch of the Defra R&D Innovation package in 2022.

There are a number of innovations already funded by the programme in areas such as insect farming, sustainable livestock feed, agricultural robotics and autonomous growing systems.

The new competition will be open to ideas addressing challenges across the agri-food sector. Priorities will include robotics and automation, which could include things like vision-guided robotic weeding systems, and novel food production systems, including vertical farming.

Funded through Defra’s Future Farming and Countryside Programme, this £12m opportunity will bring together farmers, growers and businesses, enabling them to develop novel technological solutions.

The competition has a dual-pronged approach, supporting a range of projects which can be from the initial spark of an idea through to developing transformational technologies aimed at revitalising farming practice and which can be taken up across the sector.

Farming Innovation Pathways aims to support the adoption of innovative technologies and practices, so an important aspect will be that applicants develop solutions with the engagement of farmers and growers.

The funding is split between:

- Feasibility projects (£5m): to evaluate the potential of early-stage ideas or innovations that tackle on-farm challenges, that could lead to further R&D to develop ideas into technically and commercially feasible solutions.

- Industrial research (£7m): to develop novel high-potential solutions targeting real issues affecting farmers, growers and other agribusinesses, or further develop existing solutions. This will deliver transformative solutions that tackle problems farmers are currently facing. It will include working with stakeholders to assess how solutions will be integrated within production systems to achieve widespread adoption.

The competition opens for applications on 1 Mar with a briefing event scheduled for 11 Mar.