KUHN Farm Machinery has upgraded the operating system across its range of mounted and trailed sprayers, with machines including the mounted DELTIS 2 and ALTIS 2, and trailed METRIS 2S, METRIS 2, and OCEANIS now compatible with a full ISOBUS control system. ISOBUS will also be available on KUHN’s new LEXIS sprayer which was launched in the UK at this year’s Cereals event.

The operating system upgrade brings all KUHN sprayers in line with the ISOBUS cross-industry system and enables the machines’ control system to be displayed on an in-cab terminal, such as the KUHN ISOBUS CCI unit, thereby avoiding the need for, and expense of, multiple terminals.

KUHN’s separate ISOCLICK control box provides additional operator comfort and improved ergonomics by placing the key sprayer controls within finger-tip reach at the end of the tractor seat’s armrest. This secondary control unit plugs into the CCI terminal and gives quick and easy access to functions such as section control, boom height and angle and can also be re-programmed to operate other machines such as KUHN fertiliser spreaders, seed drills and gyrorakes.

- The ISOBUS system allows the following sprayer functions:

- Provides a universal display through a single ISOBUS screen;

- Acts as a basic task controller, recording and documenting the work carried out;

- Provides location-based data;

- Manages section control and variable rate applications;

- Manages and delivers all tractor information – such as forward speed and PTO rpm.

The new ISOBUS system also simplifies the rinsing function on sprayers fitted with KUHN’s DILUSET and e-SET controls: the ISOBUS display screen illustrates which section of the machine is being rinsed (see figure 1) for improved chemical integrity and safety.

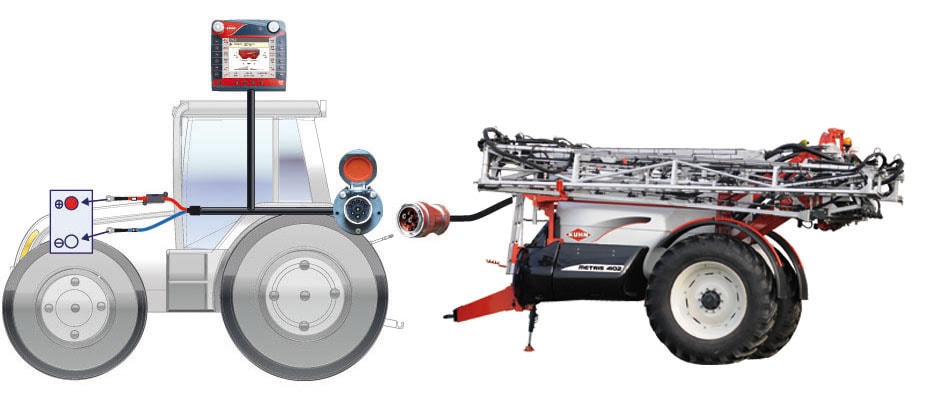

Tractors may be supplied with their own ISOBUS terminal (figure 2), or may be ISOBUS-ready – fitted with integral cable, but no control box (figure 3). Alternatively, KUHN can supply its own ISOBUS terminal as an option – this can potentially be used as the control terminal for other implements (figure 4). KUHN ISOBUS sprayers can also be operated via compatible existing terminals such as the Topcon X30 and John Deere GreenStar 2630 units.

Beyond cable connections, ISOBUS systems can also be operated wirelessly and can incorporate video feeds and external lighting bars. Not only does this type of system make it easier to control KUHN sprayers, it also saves time by simplifying tractor/implement connection, reduces in-cab clutter, and enables ‘plug-and-play’ functionality through the use of standardised plugs, cables, screens and software which are also compatible with third party GPS, mapping and variable rate technologies.

Figure 1: Rinsing sequence shown on the CCI 200 controller on a KUHN sprayer equipped with the DILUSET valve system.

Figure 2: Tractor is ISOBUS-ready and has an in-cab terminal: implement is connected to tractor’s ISOBUS plug. In-cab terminal directly monitors implement. Groundspeed is provided by tractor’s ECU.

Figure 3: Tractor is ISOBUS-ready but has no control box: implement is connected to tractor’s ISOBUS plug. Display terminal is connected via in-cab plug. Groundspeed is provided by tractor’s ECU.

Figure 4: Tractor with no ISOBUS pre-equipment: implement must be supplied with an ISOBOX control box, wiring harness and groundspeed sensor.