Can digital tools unlock benefits not seen before with precision agronomy applications? CPM finds out how an Essex farm is doing just this.

Growth stage prediction within xarvio have been annoyingly and surprisingly accurate.

By Mike Abram

It’s clear James Faulkner, partner in Robert Davidson and Son’s Newpots Farm, has long-believed in the value of precision and data driven tools for his 1350ha arable and forage business.

Yield mapping has been carried out since the late 1990s on the Essex farm, followed by using variable rate fertiliser and variable rate seed applications, with the latter consistently providing the biggest benefits.

“Variable rate nitrogen does make a difference by evening out protein but on our cold, heavy soils there’s only so much you can do to manipulate tiller numbers with nitrogen in the spring,” he says.

For variable seed rates he uses a blend of soil conductivity maps from two different companies and his tacit knowledge to create the different management zone. “Conductivity alone doesn’t always give you the truth for establishment.”

Variable rate fungicide is the logical next step from variable rate fertiliser application and seeding, believes James Faulkner.

The success with those techniques made trialling BASF’s digital platform xarvio a logical next step, along with other decision support tools, because of its ability to help set up variable applications of crop protection, including fungicides.

“It’s good BASF has the resources to do these trials as for us it was much harder to do variably applied fungicides than anything else.”

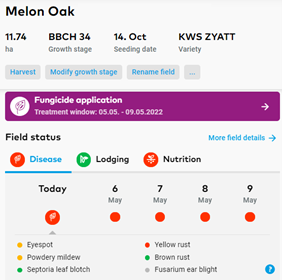

James has been involved in two Real Results field-scale trials in KWS Zyatt milling wheat using xarvio Field Manager this season, with the aim of maximising yields and optimising fungicide inputs.

The first trial uses the “Spray Timer” feature within xarvio, which takes specific information about the field and disease models to help find the optimum timing for fungicide applications.

“It’s helping to understand what the disease pressure is based on drilling date, growth stage, weather and variety specific characteristics,” explains Luke Pollard, xarvio implementation lead in the UK.

“The aim is to help growers perfect application timings, whether it’s delaying by a few days because disease pressure is predicted to be lower or prioritising fields that are rushing ahead of others.”

In the trial this season, the xarvio model suggested a one-week delay in applying T1 sprays following a dry April, and a two-week delay for the T2 spray (see table). Two tramlines of the 12ha field were treated as per the xarvio alert. “It’s hard to know at this point whether that is right or wrong. The yield will tell us at harvest,” says Luke.

It’s also a departure from the usual leaf layer designed programme timings, which most pathologists recommend as the optimum for disease control, especially for septoria control. But in the Zyatt, yellow rust has been the main disease threat which might allow more leeway on timing, he suggests.

Spray Timer is a key feature within Field Manager which provides growers with field-specific alerts for the most efficient application timing for

their crops.

“It’s looking to utilise inputs in the best way,” says Luke. “The model looks at predicted growth stages but also disease risk, so it helps support growers in delaying an application and applying when that application is needed based on that risk.”

Trials last season suggested this approach could be beneficial. Where xarvio suggested T1 sprays were delayed after a similarly dry April, it helped ensure gaps to T2 sprays remained within 3-4 weeks. Whereas for many crops the cold May, which slowed growth, stretched spray intervals past that optimum gap.

“Last year was a good example of removing emotion from decision making,” says Jonnie Dennis, BASF agronomy manager in the southeast. “And it was absolutely correct.”

“It’s a mindset change from how things are done traditionally with leaf layers,” admits Luke. “It’s why it’s beneficial to do these trials and understand farmers thoughts on doing things differently, as well as constantly helping us to improve these models.”

The model’s ability to learn is crucial, adds Jonnie. “We don’t want to get too far away from the leaf layer idea as it’s a good concept. It’s more about the algorithm learning and looking at weather patterns.”

Growth stage prediction within xarvio has been “annoyingly and surprisingly accurate”, adds James. “Every time we thought it wasn’t at the growth stage Xarvio suggested and we went to have a look, it actually was.”

In a year when growth stages rushed through in May quicker than usual, it was particularly impressive, he suggests. “It shows it takes weather into account much more than we do. Unless it’s particularly cold, wet, warm or dry, we don’t notice so much whereas the model is taking account of it on an hourly basis.”

Variable rate fungicide application

The second trial on the farm is looking at variably applying fungicides and growth regulators, based on the in-season satellite imagery collected by xarvio Field Manager – with higher biomass areas treated with higher doses.

Zone Spray is a feature within Field Manager that helps growers to apply the optimal amount of input to their crop for each part of the field by utilising variable application technology.

“It’s looking at taking the fungicide that the grower’s planning to use and optimising the rate so that it’s used more efficiently on the field,” explains Luke.

“For example, by scaling back in an area of the field that has suffered from waterlogging in the winter and hasn’t recovered in the spring or by increasing rates in areas of higher biomass, where there’s more green leaf to protect and therefore more potential.”

In this trial around half of the 44ha Pound field, or five tramlines, were treated with variable rates ranging from 20% less than the standard treatment of 0.8 l/ha Revystar XE (mefentrifluconazole+ fluxapyroxad) and 0.5 l/ha of Canopy (prohexadione-calcium+ mepiquat chloride) at T1 to 40% more, by varying water volumes in the sprayer from 80-140 l/ha.

A similar range of variation was also used at T2 from a base rate of 1.0 l/ha of Revystar XE. No growth regulator was used at this timing.

It hasn’t changed the amount of fungicide being applied, notes James. “It’s like with variable rate nitrogen or seed, it’s moving it to the areas of the field that need it most.

“The margin over fungicide cost is probably different on every part of the field so we’re just trying to improve the better parts of the field and not spend on the parts that aren’t going to produce. I think that gives me more confidence to spend money on better fungicides because you’re putting them in the right place.

“This trial is helping us understand how far we go with that – what is the right dose for the thicker and thinner parts of the field.”

The field was originally 40 separate fields so there are differences in soil type across it, he points out. “It’s a really good one to trial this type of approach.”

The process of creating the variable rate map for the trial was very simple within xarvio, he says. “It’s probably even more straightforward than creating maps for variable rate nitrogen. It’s very user-friendly compared with other systems.”

A user creates the application map within Field Manager based on the latest satellite imagery, and then decides how much to vary rates in different parts of the field, explains Luke. That map is then saved and can be exported as an ISO XML or Shape file, depending on the sprayer’s requirements and moved via a USB.

Alternatively a John Deere Operations Centre account can be connected with xarvio Field Manager allowing the map to be transferred wirelessly, while a third method is through BASF’s xarvio Connect hardware. “That’s a purple box that plugs into the sprayer terminal or a combine directly, allowing maps and data to be sent forward and back from the Field Manager app and the sprayer wirelessly.”

James has been impressed with the improvements to connectivity BASF has been delivering. “It was always a bugbear when we first started with variable rate applications. It’s becoming much easier and taking far less time. It’s no longer a barrier to doing these types of things.”

His newly ordered Amazone sprayer with a John Deere terminal integrated will make connectivity even easier, he adds. The sprayer will be equipped with Amazone’s AmaSelect CurveControl. “You can have four nozzles on each nozzle holder which it can flick between. For example, if you’re going round a corner and your standard nozzle is an 03, it will put the outside to an 035 or 04, and the inside to an 02 as you turn.

“Next season if the water rate is going between 80 l/ha and 140 l/ha, we’ll try to swap to the nozzle that’s most appropriate for that water volume and part of the field and reduce the differences in pressure.”

While that system is not necessary to variably apply crop protection, it’s important that your spray nozzles can support whatever variation in water volume you’re looking for, adds Luke.

“It’s about understanding how machinery, digital tools and other hardware, such as xarvio Connect and weather stations, can all link together and work in the best way. It’s good to see how these things are starting to integrate and bring value to growers by helping to do things more efficiently,” he concludes.

Maize becomes break crop of choice

Maize has become the break crop of choice on the farm, with around 250ha of forage maize and 100ha of grain maize in the ground this season. A further 120ha of winter forage rye is also grown, with James looking for alternatives to oilseed rape to help fill the long rotational gap required between marrowfat pea crops.

The forage maize and rye are for anaerobic digestion plants, while the grain maize heads all over East Anglia to feed mills to replace imported corn, he says.

“Forage maize has been a particularly good break for us over the past few years. We’ve had some of the best first wheats we’ve ever had after it – if we can get it established in the autumn.”

Varieties are chosen for both yield and earliness to harvest, with on-farm trials helping with selection. Access to both liquid and solid digestate from the AD plant is also a bonus, which James says brings a lot of benefits, including higher yields where it’s being used.

The crop is also playing a useful role in grassweed control. Peldon, where the farm is located, is famous for being the place where non target site resistance, or enhanced metabolic resistance in blackgrass was first found in 1984, although it’s now Italian ryegrass which James is becoming more worried about.

“We’re bringing maize onto land which isn’t traditionally maize land – such as very heavy London clays.”

He finds maize struggles on the lighter land in dry summers so he’s growing winter rye to make the most of the moisture through the winter and maize on the heavier land, which retains moisture better in the summer months.

It’s on those soils where grassweeds are more of an issue, and he’s finding later drilling helps along with multiple years of maize, if necessary. “It’s also my ‘get out of jail’ card if we can’t drill wheat behind the maize one year, we just put maize in again.”

How much does xarvio cost?

A basic package is free. This includes access to weather data and forecasts, visual field mapping and analysis, ability to add and share field notes and create flat rate application maps.

Within the basic package you can also add two fields with access to all the other available xarvio features, including satellite biomass maps, variable rate NPK and seeding, and the optimised crop protection timing, growth stage forecasts and variable rate crop protection maps.

To unlock the whole farm for the premium features costs £500+VAT.

The Real Results Circle

BASF’s Real Results Circle farmer-led trials are now in their sixth year. The initiative is focused on working with 50 farmers to conduct field-scale trials on their own farms using their own kit and management systems. The trials are all assessed using ADAS’ Agronomics tool which delivers statistical confidence to tramline, or field-wide treatment comparisons – an important part of Real Results.

In this series we follow the journey, thinking and results from farmers involved in the programme. The features also look at some other related topics, such as environmental stewardship and return on investment.

We want farmers to share their knowledge and conduct on-farm trials. By coming together to face challenges as one, we can find out what really works and shape the future of UK agriculture.

To keep in touch with the progress of these growers and the trials, click here.

This article was taken from the latest issue of CPM. For more articles like this, subscribe here.