The Valagro group, recently acquired by Syngenta, selected journalists from across the world for a tour of its R&D facility in Italy that puts biological products under intense scrutiny. CPM exclusively represented UK farmers.

“We see the future as a combination of chemical and biological complementing each other, informed by the use of data.”

By Tom Allen-Stevens

It looks like a heat lamp passing very slowly about 1.5m above the maize plants below. “We call it the plant eye,” explains Giovanni Povero, global head of plant science at Valagro.

The phenomic scanner gives very precise and detailed information about the physiology of the plant.

“It’s a phenomic scanner that gives us very precise and detailed information about the physiology of the plant. There are a number of sensors integrated into one eye that capture the parameters in real time, and that data is passed on to our bioinformatics team.”

The plants under scrutiny are sitting in a greenhouse on the rooftop of one of Valagro’s research labs at Atessa, on the coast east of Rome in Italy. The facility has 4500m² under glass where the aim is to extract every detail of biotic and abiotic stress a plant may endure, and more importantly how that can be overcome.

Scientists aim to build a digital fingerprint of

every raw material Valagro uses.

“What we’re looking to build up is a genomic fingerprint. That will tell us what genes in the plant are upregulated under specific conditions.”

Giovanni leads the delegation of international journalists down into the bowels of the building, through various labs in which some of the team of 40 scientists are extracting, sampling, filtrating and fermenting all manner of natural raw materials, from seaweed to complex fungi.

He stops by a computer terminal and brings up what looks like a thousand blobs posted within a circle on the cross-hairs of a chart. “Every raw material we use has a digital fingerprint. The chemical composition of this is so important – we need to know it’s stable and we need to know it’s consistent,” he says.

It’s this approach to biologicals that drew in the interest of Syngenta Group. The massive multinational was formed in June 2020 following a merger involving Syngenta, which was acquired by Chemchina for $43bn, Adama and China’s Sinochem. The result is a group with 53,000 employees worldwide. It’s number one in crop protection, number three in seeds and leads the field in biologicals, says global head of Syngenta Biologicals Corey Huck.

Corey Huck estimates the biologicals market to be worth $4bn (£3.7bn) at present, and this is set to rise to $10bn (£9.2bn) by 2030.

“Biologicals are not new. What’s new is the application of science, and that’s what impresses us most about Valagro – they have a very science-based approach,” he says.

Syngenta acquired Valagro, that has a turnover of $190M, in October 2020 and now the research facility at Atessa has become the main R&D centre for biologicals, and sits alongside Syngenta Crop Protection’s six other sites, including Jealott’s Hill in the UK. Together these represent an R&D budget of more than $750M/yr across crop protection for Syngenta Group.

Corey estimates the biologicals market to be worth $4bn at present, and this is set to rise to $10bn by 2030. “They’re an essential part of sustainable and regenerative agriculture, providing growers with more choices to manage resistance, improve soil health and reduce residue in foods, as well as address climate change impacts. Our Good Growth Plan has committed to invest $2bn in sustainable agriculture by 2025.”

But it’s not a stand-alone sector, he says. “We see the future as a combination of chemical and biological complementing each other, informed by the use of data.”

And it’s this marriage of nature with the intense scrutiny of science that you see throughout the facility. Valagro calls it “the third way mindset – pursuing excellence and applying science to agriculture to produce more and healthier food with sustainability at heart”.

Giuseppe Natale specialised from the start in developing naturally derived products, but uses all technologies available to get quality and consistency.

This approach underpins the company, says its founder Giuseppe Natale. “Sustainability was not really a concept when we started in 1980. But to me it’s about being a good citizen. I didn’t feel good about setting up a chemical company in the aftermath of [the chemical disaster in] Bhopal. So we set out with strong environmental principles.”

He specialised from the start in developing naturally derived products, but recognised growers needed quality and consistency and that results were not always evident from some of the natural products available.

“We have always been led by the science and aim to combine all the technologies available in our products. That’s the difference in this sector – you get innovation in crop protection, so we built a company around innovation in crop nutrition,” he says.

Giuseppe believes soil health is the challenge the industry hasn’t even recognised yet. “The degradation of our soils could have even more impact on us than climate change. Our soils are so complex and yet so ignored – we spend more money on studying the stars in the sky than we do on considering what lies beneath our feet and how it could improve the productivity of the food we grow.”

Moving biologicals into row crops is a challenge, but Camilla Corsi says scaling up is the element that plays to Syngenta’s strength.

But this is just one of many competing priorities growers have, says Syngenta Group head of crop protection research Camilla Corsi. To illustrate this, she highlights eight priorities that crop protection products aim to address, including potency, product safety, mode of action, a broad spectrum and cost efficiency. Increasingly important are climate resilience and soil health, integrated pest management and a product fit for a specific farmer, consumers and the food value chain.

“There’s no way one single technology will bring solutions to all these aspects, which is why we’re focused on delivering a very broad portfolio of products to the grower,” she says.

Modern synthetic compounds sit alongside naturally derived products, and within this there’s a broad range of technologies. This spans from micronutrients and biostimulants to RNA biomolecules, natural extracts and microbes.

The sheer breadth and complexity presents an R&D challenge, but Camilla believes “digital will provide a way to refine the R&D. That’s not just about how we explore the technology in the lab, but also how it’s applied in the field.”

She highlights Syngenta’s digital farming platform Cropwise, with close to 80M ha now digitally connected worldwide, 16.5TB of images from seeds and crop protection R&D and commercial use cases available for analysis, and with datasets that include soil samples drawn from over 400,000 locations over the past 20 years. “Data will provide the predictive model to deliver tailored solutions to crops and fields.”

But are these “tailored solutions” actually available to row-crop growers, especially in the UK? Despite the huge size and potential of the market, 70% of biological products are currently used in speciality crops. “Moving into row crops is a challenge, but scaling up is the element that plays to Syngenta’s strength,” says Camilla.

Within Europe, however, there is also the regulatory challenge. “Biocontrols come from different backgrounds, and we need to demonstrate they are safe. But we cannot provide a full regulatory package for every single pathway influenced by a biological product as we do for synthetics under the current EU hazard-based regulatory process.

“We should move to a more risk-based system, and I think there is now recognition for this within European regulatory authorities and a willingness to have a different discussion around biocontrols.

“When it comes to the UK, we are encouraged by the moves made to promote progress of technologies such as gene-editing. We hope the UK will take the lead and help us showcase to the EU the benefits of the developments we’re bringing forward,” concludes Camilla.

Putting science into biostimulants

Valagro has branded its 30 years’ experience and current approach in working with natural growth in plants as GeaPower. This “innovative technology platform” has some core aspects:

- Extraction and understanding – Valagro claims its experience with its raw materials have refined both the best method to separate out the active components and the knowledge on their biological and chemical characteristics.

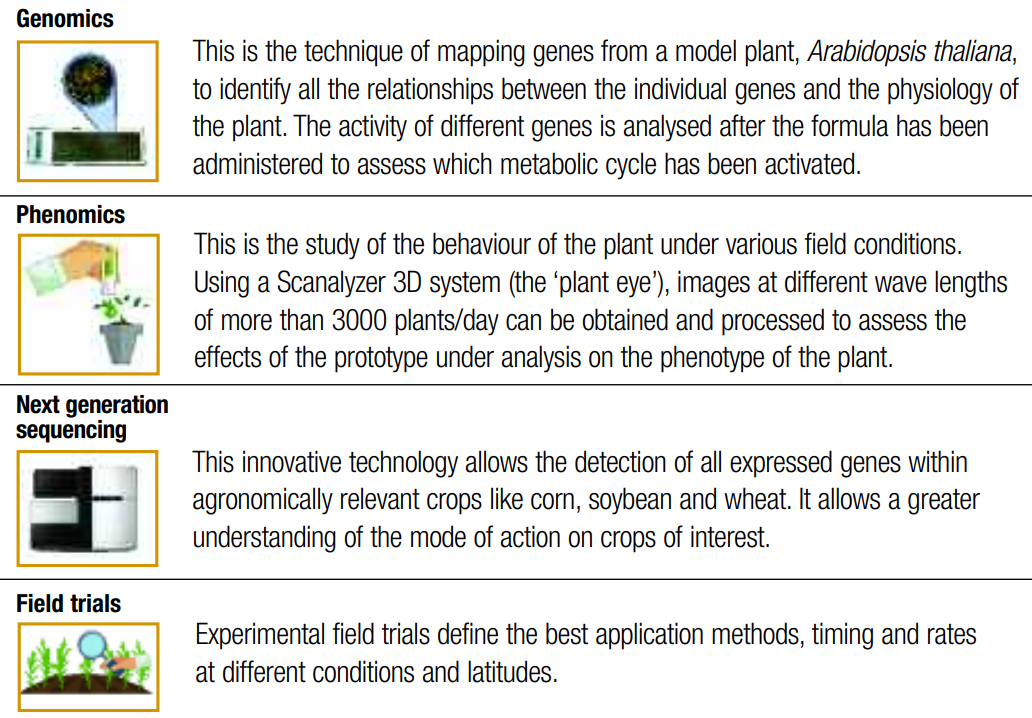

- Cutting-edge analytics – genomics, phenomics, proteomics and metabolomics are used to decipher the genetic and molecular triggers and obtain specific physiological responses in plant systems (see below).

- Selection and formulation – once a thorough understanding of the active ingredients and their pathways has been established, the extraction methods are refined and a solution that delivers the desired outcome is developed.

More crop per drop thanks to biostimulant prop

The drought that struck across Europe has been a sobering sign of the issue of water scarcity now threatening crops worldwide, notes Valagro senior product manager Alfredo Sgrignuoli.

“As many as eight of the 17 sustainable development goals introduced by the UN in 2015 are linked to water use efficiency (WUE). 70% of the world’s freshwater is used for agricultural activities,” he adds.

Talete is claimed to increase crop water productivity, both when water is scarce and when there is plenty.

Valagro’s answer is Talete, a biostimulant claimed to increase crop water productivity (CWP). “It’ll give you more crop per drop, both when water is scarce and when there is plenty,” says Alfredo.

Talete has come about through Valagro’s studies of plant phenomics and matching these to the properties of plant-derived biomolecules of the natural raw ingredients the company uses.

Studies show it increases CWP through a biochemical action on the plant physiology maximising yield, without changing the volume of water used for irrigation, explains Alfredo.

“On the contrary – we’ve found growers can reduce irrigation volume, extend intervals between irrigations, or skip irrigation turns, without loss of crop productivity. Using Talete without any reduction in irrigation volume allows the plant to optimise water use, reducing possible water imbalances that often remain hidden between irrigation shifts, so you can achieve the so-called ‘bridge effect’,” he adds.

It works on the plant through two main mechanisms: improving water retention and water absorption, and optimising water use efficiency (WUE). The former occurs through the induction of and early response to genes reactive to dehydration, such as dehydrin, as well as an adjustment of stomatal regulation.

WUE is boosted through Talete, causing an increase in photosynthesis by regulating the activity of certain genes involved in this process, including those responsible for biomass allocation. “Phenomic analysis has shown up an increase in some health indices,” notes Alfredo.

He points to Valagro’s bioinformatics processing, which analyses metabolic pathways. This suggests Talete can induce key genes for the growth and physiology of the plant, such as geranylgeranyl diphosphate (GGPP), an important intermediate isoprenoid that is converted into gibberellins, carotenoids and chlorophylls.

Results in the field back this up, says Alfredo – 481 trials worldwide showed an average increase in production of 9% in vegetables, orchards and row crops. The standard total rate is 20 l/ha, applied in up to four doses direct into irrigation water.

There are currently no plans to launch Talete in the UK, but investment into the research, development and launch of biological products for the UK market is an important part of Syngenta and Valagro’s activities, says Dave King, Syngenta technical lead for UK, Ireland and Nordics. YieldOn, sold by Valagro in the UK for cereals and oilseeds has shown yield benefits averaging around 0.5t/ha for winter wheat in distributor trials, he points out.

“With the challenges that growers in the UK are facing from increasing volatility in climate, input costs and markets, biologicals will be an ever-more important tool in ensuring the crop is best prepared for this unpredictable environment, protecting a grower’s investment.

“We apply the same scientific and agronomic rigour across our whole portfolio. Building a deep understanding of these products and how they fit within arable systems in combination with other products and decision support tools is key to ensuring the quality and performance of biological products we offer to growers,” notes Dave.

Corteva buys into biologicals

Corteva Agriscience is to acquire Spanish microbiological technologies specialist Symborg for an undisclosed sum. The agchem giant has been working closely with a number of biological companies for the past three years, says executive vice president of crop protection Robert King.

“Acquiring Symborg is a significant next step in Corteva’s strategy to accelerate the development of its biologicals portfolio, and it shows Corteva’s progression towards further establishing itself as a technology leader in this rapid growth segment,” he adds.

Corteva first collaborated with Symborg to scale up and bring farmers Utrisha N, the nutrient-efficiency product launched in the UK in time for the 2022 crop season. The natural-origin biostimulant enables plants to fix nitrogen from the air and make it available to the plant.

This article was taken from the latest issue of CPM. For more articles like this, subscribe here.