Minimising seed return is a crucial part of blackgrass management and its importance may often be underestimated. CPM finds out how to achieve this in the fifth of the ‘five strategies for five years to control blackgrass’ series.

Destroying the weed to stop seed return is the only real way of decreasing resistance evolution.

By Lucy de la Pasture

Blackgrass is a weed that biologists describe as fecund, meaning it has a propensity to produce a very large number of seeds. In an AHDB project published in 2016, the seed return in untreated crops was estimated to be 87,959 seeds/m2. For this reason, a target of at least 97% control of blackgrass is necessary in each and every year to prevent the problem from escalating.

Dr Stephen Moss highlights that because pre-emergence herbicides generally worked very well last autumn, it’s important not to lose sight of the high level of overall control needed to manage blackgrass populations.

“The level of blackgrass control was quite high last autumn but don’t be lulled in to a false sense of security because populations look lower than they were last spring. Any spring survivors are likely to be the really hard-core blackgrass that’s most difficult to control and you don’t want this seeding and perpetuating any resistance problems,” he explains.

Harry Strek, scientific director of Bayer’s Weed Resistance Competence Center in Frankfurt, Germany, believes minimising seed return should the primary objective where blackgrass is concerned. He explains that when blackgrass arrives in a field, it has a habit of catching growers unawares because initially the odd plant goes unnoticed, even over several seasons. It continues to set more seeds and eventually patches appear.

“It’s only when blackgrass is about 10% of the crop population that you can see it in patches. In the next season its numbers increase massively because the seeds will have already been produced, will find their way to the ground, and it’s too late to do anything about it. At 20% of the population, yield losses become severe,” he says.

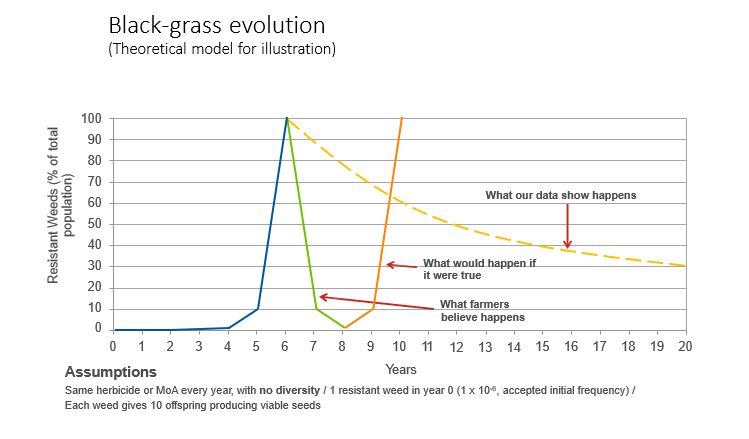

Harry says there’s a widespread belief that a blackgrass problem develops in a year or two, but he explains problems are a result of a series of events over several years which allow the blackgrass to build up and eventually reach a crisis level. Once resistance has become established in the population, then minimising seed return becomes even more crucial, he highlights.

“In Bayer landscape studies we’re still finding 30% ACC-ase resistance in the population 15 years after a herbicide from that group of chemistry was last applied. So if a resistance occurs in a field, it stays there,” he says.

“Weeds accumulate resistances and resistance mechanisms, they don’t trade them off. Some blackgrass plants can have three different ACC-ase resistances plus metabolic resistance.”

Spraying patches of blackgrass out with glyphosate for successive years is the best way to get on top of hard-core blackgrass.

This indicates the resistance mutations don’t seem to carry much of a fitness penalty, says Harry. And to him, this ability of the weed means minimising the chances of new genetic combinations entering the seed-bank should be the focus where blackgrass is concerned.

“We need to concentrate on stop-seeding as a yardstick for blackgrass control to minimise the chance of weed competition in subsequent crops, rather than continue to concentrate on using weed biomass (heads/m2) as a measure of a blackgrass problem in a field, ie the amount of weed competition.”

“Because blackgrass grows in patches this provides an opportunity to find an attack point to limit the evolution of the weed within the field,” says Harry.

Spraying out patches with glyphosate, or hand-rogueing where populations are low enough to be practical, are both ways of stopping seed return, says Stephen. He recommends the first week of June is usually an ideal time because the blackgrass has headed but seeds haven’t begun to shed.

“Although seed loss from heads begins to occur from mid-June, useful reductions in the blackgrass population can be achieved up until the end of the month. If blackgrass is being mown off, there’s the opportunity for weed regrowth so this approach needs to be managed well and probably repeated to be effective,” he notes.

Stephen also believes it’s worth spraying off the same patches for a number of years to help reduce the input of new blackgrass seeds into the seed bank. This is much more feasible now given the recent advances in GPS technology and field mapping.

“I’m surprised so few farmers take this approach as it should also be effective at preventing small patches becoming bigger patches, so is well worth considering,” he adds.

“Patch spraying is likely to be a worthwhile exercise, even in the years when the blackgrass isn’t as obvious. Apart from the infestation level, this may be due to the crop variety or PGR effects on the weed keeping the blackgrass below the crop canopy,” he suggests.

Harry agrees that although drastic, spraying out patches with glyphosate is an effective means of reducing seed return and also brings big benefits in addition to reducing weed density. “Destroying the weed to stop seed return is the only real way of decreasing resistance evolution,” he adds.

As well as the more traditional methods of stopping weed seeds return to the seed-bank, Stephen points out there are some novel ideas that may help reduce seed return in some situations, but he remains to be convinced of some of their merits.

“Other options include the CTM Weed Surfer, which chops off the blackgrass heads above the crop, and Australian inventions, the Harrington Seed Destructor (HSD) and chaff tramlining,” he points out.

The Australian machinery which captures seed has been found to be useful in managing resistant ryegrass, which doesn’t tend to shed so much of its seed prior to harvest. Stephen believes they may offer more potential in the earlier harvested barley and OSR crops than in winter wheat crops where blackgrass is the problem.

“Bromes and ryegrass retain more of their seeds at harvest so would be better candidates for the HSD and chaff-tramlining in wheat,” he says.

In any case, minimising the spread of seeds and weed plants in combine harvesters, balers, cultivation equipment, straw or manure is good practice where blackgrass is concerned, he points out.

Harry highlights the importance of understanding the degree of weed control needed to keep a blackgrass population in decline or at least stable.

“Letting control slip by small amounts, for instance by discontinuing a non-chemical treatment that had been contributing 7% control, will allow blackgrass populations to recover rapidly. You can’t let your foot off the gas pedal,” he warns.

Australian chaff deck trialled in UK

The chaff deck, more widely used in Australia to control ryegrass seed return, was fitted to Essex farmer Jeremy Durrant’s Lexion 780 and covered 1250ha in 2017 as part of joint trial investigating its suitability under UK conditions.

The research is led by Frontier Agriculture as part of its 3DThinking trials programme and is organised in collaboration with EW Davies Farms, AHDB, Primary Sales from Western Australia and Rothamsted Research.

Frontier Agriculture’s Dr Paul Fogg explains the idea behind the chaff deck is based on a working hypothesis that 95% of any weed seeds that enter the combine header end up in the chaff.

“On a standard combine set-up, the chaff spreaders would simply distribute the seed, in essence planting next year’s problem. What the chaff deck does is to consolidate the chaff, along with any weed seeds, and deposit it in 20-30cm wide tramlines behind the combine wheelings.

“The lighter weed seeds tend to sit within the chaff, with the theory being that over time it becomes a mulch, creating a hostile environment which helps rot the weed seeds and in the process mitigating seed germination and viability,” he explains.

Unlike ryegrass, which retains 80% of its seed at harvest, blackgrass begins to shed seed before harvest so the effectiveness of the chaff deck in a blackgrass situation was largely unknown.

The main trial site was cropped with the hybrid winter barley Volume, with a background blackgrass population assessed at 219 plants/m2, explains Paul. “The crop was harvested on 14 July 2017 and we estimated 30-50% of the blackgrass seed was retained in the ear.”

Within 11 days of harvest it was clear to see the volunteer barley plants germinating within the chaff tramlines, describes Paul. “This initial relative rapid germination of volunteer barley plants may have been a direct result of their greater specific weight relative to the blackgrass seed and chaff, and the fact that they fell to the base of the chaff line and had better contact with the soil and available moisture.”

A noticeable observation within the first few weeks post-harvest was that chaff in the tramline itself seemed to sit slightly proud of the soil surface and afforded a drier microclimate relative to the rest of the field, he notes.

The following OSR crop was established with minimal soil disturbance, with the seed applied to the soil surface and followed up with a straw rake and rolls to create a shallow tilth. Blackgrass plant scores were made at the start of Oct within the standing crop, with initially quite encouraging results.

“Although not uniform across the entire field, the average background blackgrass population with the trial field (based on plant counts) was 46/m2. This compared to plants counts of 274/m2 within the chaff tramlines, a six-fold increase. The field has subsequently been subject to normal agricultural practice with no special treatments applied to the chaff tramlines.

“Practice in Australia varies, with some farmers leaving the concentrated weed seed to decompose in the chaff tramlines and others are using a concentrated pre-mix program only on the tramlines. Jeremy is taking the view that he’s now consolidating his weed seeds year-on-year and will review the outcome before deciding whether any further intervention is required,” explains Paul.

Although the trial was evaluated under a controlled traffic system (CTF), with everything operated on 12m spacings, it’s not a necessity if you’re considering using the chaff deck for tramlining.

“Provided the same combining lines are maintained each year the system will work. In Australia, it’s reported many growers carry out post-harvest cultivations at a different angle of travel to the combine swaths,” he comments.

Based on one year’s results there are now some positive indications that its mainstream success in Australia could be replicated in the UK, believes Paul. “Harvest weed seed management and the use of chaff decks for tramlining isn’t a silver bullet but could prove a useful tool, especially where harvest is early.”