Revysol has a chemistry that gives it many useful properties in the field. CPM finds out how this may translate into more spraying opportunities and reliable performance.

Chemistry that will bring control back to the grower.

By Lucy de la Pasture

When the team from BASF reviewed the results from the first trials of Revysol (mefentrifluconazole), even they were surprised, according to Dieter Strobel, responsible for the company’s technical market development for cereal fungicides in Europe.

“We saw Revysol was giving stunning efficacy, even better than we’d expected and far superior to other chemistry. The advantage it was showing grew over time due to the continued erosion of efficacy in the older azoles,” he comments.

“In high disease pressure situations, the strength of Revysol was particularly noticeable. Where conventional products were struggling, it continued to provide control of septoria.”

In total more than 1,000 field trials were carried out using Revysol throughout Europe and by summarizing all the data BASF were able to link aspects of its performance directly to some of the new azole’s chemical properties and its clever formulation.

“Revysol has very low solubility, so it was a real challenge to our chemists to formulate a product that would be easily taken up by plants. They found a way to formulate Revysol in a way that makes it available as free molecules and not crystals in an emulsifiable concentrate (EC),” he explains.

The work of the formulation chemists means Revysol is taken up very quickly by plants, which is an essential property for an azole fungicide to be effective.

“Quick uptake makes an azole effective, but we learned from our experience with epoxiconazole that it can also mean that its longevity of performance may be limited. In trials, Revysol clearly had a longer-lasting efficacy than either epoxiconazole or prothioconazole, which was surprising. We’d expected its quick uptake to mean Revysol would have a short duration in the plant, but this isn’t the case,” explains Dieter.

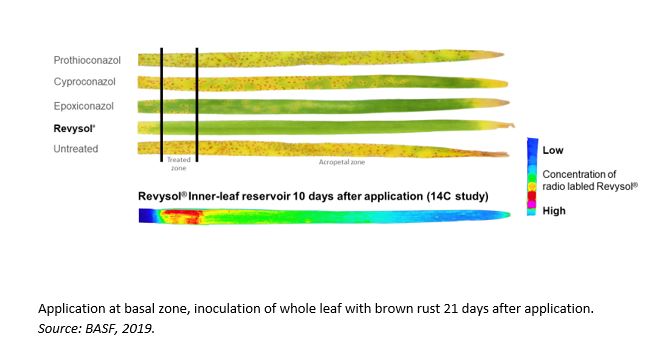

He explains the unexpectedly long duration of Revysol’s action as being down to the solubility of the molecule. It’s made ‘artificially’ soluble using formulation wizardry to get quick uptake into the plant, but once inside the leaf it reverts to its normal insoluble state.

“It’s so insoluble that only a few Revysol molecules at a time can make it to the end of the leaf. In other words, it has a low but consistent level of translocation in the leaf.”

Rather than being a disadvantage, the high intrinsic efficacy of Revysol means that traces in the leaf are enough to control the septoria pathogen. The advantage of its slow rate of movement is that once the Revysol has got into the leaf, which happens quickly, it remains as a rich inner-leaf reservoir to constantly release low levels of active substance towards the leaf tip.

Systemic biotest wheat

So how does Revysol’s quick uptake but slow translocation translate into properties that are of benefit in a field situation?

“Its rapid rainfastness, just 15 minutes, can be explained by Revysol’s fast uptake. When leaf wetting occurs, the chemistry is already protected within the leaf so it can’t be washed off,” explains Dieter.

The same dynamic properties of Revysol also make the fungicide very stable to UV light, which is known to influence the performance of some other azoles.

“We’ve experienced some hot summers in recent years, and prothioconazole gave a relatively poor performance in the field where high UV conditions occurred, which can be linked to UV-degradation of the fungicide. Revysol is held within the leaf so is protected from UV light,” he explains.

A further benefit of Revysol’s chemistry is that its quick uptake means it isn’t influenced by temperature in the same way as conventional azoles, where cool weather can limit uptake. “All of these characteristics – rainfastness, UV stability and temperature independence – all mean more opportunities to go spraying without concerns about reductions in efficacy.”

BASF has developed a ‘Benefits Finder’ app. which helps illustrate how much the spray window can be ‘stretched’ when using the new chemistry. Dieter gives an example where over the period of a week, the rainfall amounts meant six days were possible spray days (threshold: 5mm/day). Of these only three were optimum for the application of conventional products, while Revysol would perform on all six days – even when the temperature dipped below 13⁰C and there was rainfall forecast.

Steve Dennis, BASF head of business development in the UK, says the effects of climate change mean we’re experiencing much more variable weather patterns in the UK, with an increasing tendency to get ‘stuck’ within prolonged periods of wet or dry conditions.

“Adding to the difficulties is that septoria is becoming more adapted to our current chemistry. The combination of the loss of curativity from azoles and disruptive weather means it’s becoming harder to get fungicide timings right,” he says.

Steve sees Revysol as “chemistry that will bring control back to the grower.” While he emphasises the importance of correct fungicide timings in providing optimum protection to the leaves of the upper canopy, the properties of Revysol mean that it doesn’t matter as much if the weather does intervene.

“Weather is unpredictable, especially in the UK, and fungicide application is all about the weather. Revysol means there’s less need to predict, which takes some of the worry out of application.”

In 2019, heavy rain fell across the UK and Ireland in June, a couple of weeks after flag leaf sprays had been applied, and septoria “went mad”. It was a disease situation that would have been a lot worse if chlorothalonil (CTL) hadn’t been widely used, believes Steve.

“CTL is a long-term, effective protectant fungicide and has given flexibility if following timings haven’t been quite right, so it hid the effects of less than optimum fungicide inputs. In a world without CTL, we’re going to have to be a lot more on our toes,” he comments.

Revystar XE (mefentrifluconazole+ fluxapyroxad) will bring much-needed flexibility and curativity and the BASF recommendation is for a programmed approach at T1 and T2 timings, says Steve, though he accepts that in many situations it will be used just once, at T1 or T2.

“The evidence for using Revystar at T1 is strong and if there’s a wet period, then it really is the product of choice,” he believes.

The full label rate for Revystar is 1.5 l/ha, but agronomists will use their discretion to dose appropriately according to disease pressure and varietal resistance, he adds. “Revystar at 1.0 l/ha offers a great performance and value compromise, but higher rates may be necessary in some circumstances. There may also be situations at T1 where 0.8 l/ha will be suitable but at T2, I don’t advise using at rates below 1.0 l/ha,” he says.

Steve says the very slow apical translocation of Revysol means it has a very good crop safety profile, avoiding some of the scorch effects seen with faster moving fungicides.

Revystar will also offer good control of brown rust, where its performance is equivalent to market standards, says Steve. “For yellow rust control, the addition of a strobilurin will be beneficial. In terms of mildew and eyespot control, Revystar’s performance is equal to prothioconazole.”

The demise of CTL will leave one of the biggest holes in programmes to control ramularia, where it has become the mainstay since instances of resistance have been reported to single-site chemistry, including azoles, strobilurins and SDHIs.

“We’re seeing Revysol maintain its performance against azole-resistant strains of ramularia compared with prothioconazole. It’s a disease that develops in response to stress so it’s important to manage crop stress as well, part of which is good early season disease control.”

The Irish experience

Dr Steven Kildea has been keeping a keen eye on Revysol in trials at Teagasc’s Crops Research Centre at Oak Park in Carlow. Septoria pressure is at its highest on the Emerald Isle, which marks the westerly horizon of wheat growing in Europe.

It was Ireland where the first slip in SDHI activity was experienced, with the UK following close behind. Since then, it’s CTL that has been supporting fungicide chemistry and may be partially responsible for stabilising the situation, he believes, with little further erosion of SDHI activity seen since 2017.

“New chemistry is very welcome and in trials, we’re seeing Revysol moving the yield contribution from the azoles back up to where they used to be,” he says.

Disease development is so strong in Ireland that fungicide programmes need the most highly active ingredients throughout the programme, with as much emphasis on the T1 timing as at the T2. Diversity is the key to resistance management as it allows growers to potentially reduce the dose used or the number of times individual actives are actually applied, so Steven is keen to include different chemistry in fungicide programmes.

“We have the opportunity to use fungicides better, having learned from our past experiences. The septoria pathogen will most likely evolve in response to selection pressure and we’re not starting with a native population of septoria. It’s the pathogen’s ability to accumulate mutations that poses the biggest threat to Revysol.

“We’ll need to be very careful about how we protect this new chemistry, otherwise we won’t get the same amount of time we’d had with the other azoles before their performance was eroded.”

Part of that process will be careful agronomic choices, which make a big contribution to disease control, he says. “It comes down to local decisions– matching the rate of fungicide applied to disease pressure will reflect the season and agronomic factors, such as varietal resistance and planting date.”

“Under Irish conditions we need very high cultivar resistance before you can reduce the rate of fungicide without affecting yield. We still see yield responses to fungicides in cultivars with septoria resistance ratings in the high 7s.”

Ramularia is a disease that poses one of the biggest problems with the imminent withdrawal of CTL. Teasgasc has conducted trials to assess the contribution of different actives to its control in both winter and spring barley at the T2 timing.

“As we anticipated, CTL gave the best control of ramularia. We found the performance of SDHI applied at full-rates to be disappointing, so resistance has had a significant impact on their efficacy. Proline (prothioconazole) has also been significantly impacted but it gave better control than we’d anticipated and above that of the alternative multisites, folpet and mancozeb.

“Revysol gave decent control of ramularia in the trial, offering a level between CTL and Proline, so it will help take the pressure off prothioconazole. Whilst the loss of CTL will clearly be felt we will be able to manage ramularia. The crop won’t be completely clean but that’s not necessary, as long as grain numbers and fill is protected enough to maximise yield potential.”