The future of crop protection remains widely unknown, but there’s an increasing number of alternative ways to protect chemistry while achieving optimum crop performance. CPM seeks answers to growers’ questions on what these are.

The application of crop protection products can be a very inefficient process.

By Charlotte Cunningham

Chemical efficacy has come up against a number of challenges in the past few years. Though they’re an essential part of crop management, over-reliance on some chemical products has caused resistance to build up, weakening their effectiveness.

As chemical efficacy reduces, the presence of pernicious weeds, diseases and pests increases. Blackgrass is one of the biggest concerns for arable growers, with yield losses estimated at 0.4-0.8t/ha among populations of just 12-15 plants/m². And this was confirmed in a recent survey conducted by CPM and Interagro – 76% of farmers said blackgrass was one of their main agronomic concerns this spring.

“With multiple herbicide resistance, no new grassweed modes of action on the horizon, and regulatory pressures on the existing toolbox, obtaining 97% blackgrass control in a non-inversion tillage system – required to prevent populations increasing – isn’t an easy target to achieve,” explains Emma Ralph, director at Interagro.

Tom McCabe, lecturer in crop science at University College of Dublin agrees: “Over the past decade, blackgrass has become a big problem. When they work well, chemical controls are very effecting, but we can’t depend just on chemistry to solve problems.”

Septoria resistance also ranked highly in terms of concern, with 68% of growers noting this as an issue. “Septoria is the most damaging foliar disease of wheat, with losses ranging from 30% to 50% in high pressure years,” says Emma. “Reduced sensitivity to azoles and emerging resistance to SDHIs makes septoria the biggest cereal disease challenge.”

Despite this, we’re in a far better position now – in terms of controlling issues like blackgrass and septoria – than we were 5-10 years ago, says Trevor Smith, director at Plantability. “Farmers are now moving away from just chemical control and looking more at cultural methods and cultivations. It’s opened peoples’ eyes to the fact that there could be another issue around the corner.”

While chemical controls have long been the go-to solution to tackle yield-robbing weeds, diseases and pests, their effectiveness has been questioned, with 64% of growers claiming a major issue with reduced efficacy due to resistance (see chart on pxx2). “Compared to where we were 10-20 years ago, we’ve noted a consistent trend with high efficacy products reducing in effectiveness,” says Tom.

While using something out of a can is a very easy solution, with good agronomic advice there are strategies that can be put in place to minimise resistance, adds Trevor.

The key to managing or preventing resistant populations is to minimise survivors. That means being able to differentiate between poor control due to resistance, and poor control from either poor application or sub-optimal conditions for products to work effectively, explains Emma. “The application of crop protection products can be a very inefficient process as there are a lot of potential barriers that can prevent the chemical reaching its target, be it inside the leaf of the crop to tackle a septoria infection, or uptake into a small blade of blackgrass.”

These barriers may be biological, where, for example poor herbicide coverage can allow blackgrass to germinate, or where there’s poor fungicide coverage that can lead to scattered infection. Alternatively, they may be physical, such as the waxy leaves of weeds and crops that can be hard to penetrate with herbicide or fungicide.

There does however, need to be a greater consideration into the fact these barriers exist, with only 18% of growers citing poor coverage and 21% considering poor uptake as reasons for poor control, states Emma.

Hard water and high pH can also be a cause of poor control with 41% of growers stating this as an issue for them and 69% opting for a water conditioner to address the problem. “Stale seedbeds are one major area that can be affected by hard water, common in the major blackgrass areas of the UK. In hard water, calcium and magnesium cations lock up glyphosate, reducing availability of the active molecule for weed control,” explains Emma.

“High pH also prevents uptake of the active ingredient. Both hard water and high pH will reduce weed control, and in these situations the water must be engineered with a suitable water conditioner if effective weed control is to be achieved.

“Poor stubble cleaning can not only delay the drilling of the next crop but also put greater pressure on pre-emergence herbicides to do a good job.”

So, with chemical efficacy under scrutiny, what products are available to aid the effectiveness of chemistry and protect yield and quality, aside from the use of water conditioners with glyphosate? According to the survey, 93% of farmers are using adjuvants.

“If blackgrass is an issue on farm, growers will be using adjuvants,” says Trevor. “However, we also need to think about using an adjuvant with fungicides and insecticides. Depending on what chemistry they’re used with, adjuvants can increase plant coverage – and subsequently penetration – and give better uptake.”

Trials on winter wheat in the UK during 2016 and 2017 have shown significantly improved septoria control – and also green leaf scores – when adjuvants were applied with key triazoles plus SDHI fungicide products at early and mid-season timings, notes Tom. “This then follows through into higher yields.”

A large proportion – 73% – of growers agree that adjuvants have a role to play in the resistance management of crop protection products. “Using adjuvants with residual herbicides is less common, yet extremely valuable, adds Emma. “With the potential to improve blackgrass efficacy by as much as 8%, adjuvant technology has an important role to play in both optimising yields and margins on-farm and in resistance management strategies.”

Though adjuvants themselves can’t prevent or reduce resistance, what they can do is present chemistry in the best possible way to the plant to encourage uptake and maximum coverage, explains Trevor.

According to Tom, the issue isn’t confidence in products but an uncertainty of when best to use them. “Especially when using complex tank mixtures, there can be a lot of hesitancy around when is best to include adjuvants. When used correctly, adjuvants have the potential to improve other chemical products. Most crop protection products have moderate to variant efficacy, and adjuvants can have a positive effect on this.”

Relatively new to the market place and offering a different approach to optimising crop production are biostimulants, with only 30% of growers using this type of product to aid efficacy or protect quality and yield. Despite this, biostimulants are certainly gaining more traction in the industry, with many growers looking to protect crops and yield potential from all angles – not just with traditional crop protection products.

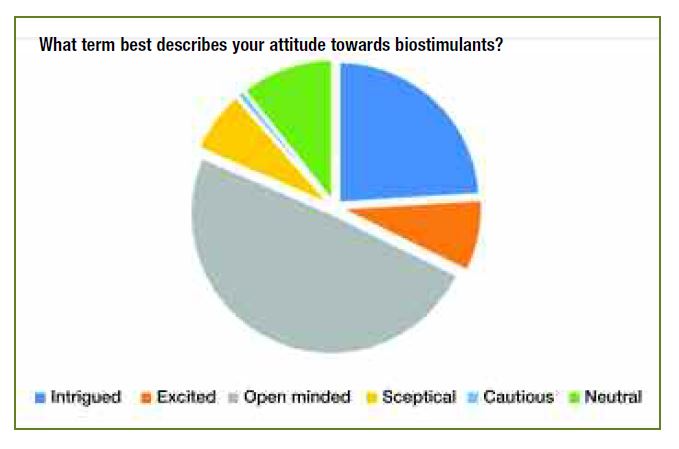

This shift in attitude was reflected in the survey, with nearly half (49%) of growers saying they were open minded about biostimulants and only 7% describing themselves as sceptical.

Despite this, more needs to be done to educate farmers about the wider benefits of biostimulants, adds Tom. “Biostimulants are a really interesting product, but again, there’s a knowledge gap surrounding the best situation to use these products. We need to widen the knowledge base.”

But mystery still surrounds the concept of biostimulants, so what exactly are they?

Agricultural biostimulants are substances that have the capacity to modify physiological plant processes which, when applied to crops, have the potential to relieve stress and benefit growth, development, and subsequently, yield, explains Emma.

“They come in a number of forms which can be classified into two groups: Non-microbial and microbial. Microbial options include plant growth-promoting bacteria and rhizobacteria, while non-microbials include seaweed extracts and amino acids.”

So, when can they be used? Biostimulants have proven to alleviate the impact of weather extremes such as drought and cold which have put crops under stress. “They can also work to alleviate sub-optimal nitrogen use and provide a nutrient boost during critical phases of growth,” she adds.

As interest grows around these products, so does their availability on the market, meaning that choosing the correct option can be tricky. When it comes to selecting a biostimulant product, growers ranked trial results, potential to improve yield and quality, and proven return on investment as their priority areas (see chart on pxx6). “There’s a lot of trial work to prove the effectiveness of these products now,” says Trevor. “If anyone is in doubt, they should split a field and try it themselves. It’s all about seeing the results for themselves.”

Interestingly, only 28% of growers said that using a plant-based, rather than animal-based, product was important. Though this may not be of imminent concern to growers now, it’s a factor that may have more of an influence in coming years, explains Emma. “Animal-based amino acids can’t be fully utilised by the crop. There are also growing food safety concerns about their use on the edible parts of crops – leading to their ban for use on milling wheat in 2017 by nabim.”

While these products can certainly provide tangible benefits to growers, she says, they’re not a silver bullet. Farm profitability depends on several factors, which vary from farm to farm. According to the survey, improving soil health would have the biggest impact on farm profitability, with 34% of growers noting this as a key area. “Micronutrients can be hugely beneficial to soil health, and there’s a lot of evidence to suggest some biostimulants can help with soil biology,” she adds. “But of course, the starting point is to get soils analysed and look carefully at any areas of weakness.”

While the future of arable chemistry hangs in the balance, farmers need to utilise all control options available to protect what chemistry is available, says Emma. “With accumulating resistance pressures on-farm, optimising the performance of crop protection products is crucial, not only to reduce selection pressure to protect chemistry, but also to protect yields, profitability and crop viability for growers.”

The buzz around Bridgeway

Bridgeway is the latest biostimulant offering from Interagro, which appears to be gaining major interest from both distributors and farmers, with 72% of growers surveyed saying they were interested to know more about it.

Bridgeway is an amino acid-based product, proven to aid crop health and increase yields. “Amino acids are the building blocks of every living cell,” explains Emma. “In good conditions, plants can usually produce all 20 amino acids they require, but in conditions such as poor light or drought, photosynthesis is inhibited, and amino-acid production is reduced at a crucial stage of crop development. Bridgeway provides all 20 amino acids required by the crop for optimum protein formation.”

Derived from plant origin, it can be applied as a foliar spray on all agricultural and horticultural crops (organic or conventional), with no restrictions in application timings. Following two years of replicated trials and a year of on-farm testing on a variety of crops, Bridgeway is available to growers this spring.

Optimising adjuvants

In what situations can adjuvants be used?

- Where herbicide, fungicide or insecticide efficacy is compromised by resistance.

- Applications to waxy leaves that can be hard to penetrate with fungicide, herbicide, or PGR.

- When herbicides or PGRs are being applied in cold weather and uptake may be compromised.

- Where tank mix compatibility is an issue – e.g. chlorothalonil.

- Where coverage is critical, e.g. pre-emergence herbicide applications; small blade of blackgrass post-emergence; T1/T2 fungicide applications in cereals; ear protection at T3 to prevent fusarium; blight protection to prevent tuber blight.

- To minimise risk of herbicides leaching into groundwater.

Biostimulant answer brings top prize at Royal Ascot

Congratulations to James Haggart who responded to the CPM/Interagro survey and has won a fabulous prize of a day out at the prestigious Royal Ascot. He’ll get two hospitality tickets for the Panoramic Restaurant in the Royal Enclosure – a prize worth £2,877.

James responded to the survey and completed the tie-breaker question on the best use of biostimulants, with the answer deemed best by the judging panel: “to encourage plants to grow and produce to their full potential”, was his suggestion. This has earned him and a companion a dining experience at Royal Ascot from Michelin star chef Raymond Blanc, and views of the racing and Royal Procession from a private balcony.

To take part in the next survey, make sure we have the correct details for you by emailing angus@cpm-magazine.co.uk