Adjuvants may be a forgotten resource when it comes to blackgrass control. CPM finds out how Backrow adds its weight to the scrum against the mighty grassweed.

One of the components of success in delivering a pre-em herbicide is the number of spots on the target.

By Lucy de la Pasture

The mantle of blackgrass control has passed to residual herbicides in recent years as post-emergence herbicides have lost their grip on the pernicious weed. In a favourable year, pre-ems can deliver high levels of control, but the 97% required to prevent a population explosion is often hard earned and difficult to achieve in practice.

With no one herbicide or cultural control method able to deliver the level of blackgrass control needed, wringing out every percentage point of control at the pre and peri-em herbicide timings is crucial. So is there a way to maximise their performance?

Agrii regional technical adviser and Cambs grower, David Felce, believes by understanding the basics of the spray delivery system and knowing what you’re trying to achieve, then it’s possible to engineer the water to your advantage. And this is where adjuvant Backrow has a valuable role to play, with Agrii trials consistently demonstrating improved blackgrass control from pre-em herbicides where it’s added to the tank, he says.

At the pre-em timing the target is the soil, which rather than being a two-dimensional surface David describes as probably the biggest canopy you’ll ever spray. “The tools to manipulate the coverage of a herbicide on the soil surface are water volume and spray quality and these are independent of one another.

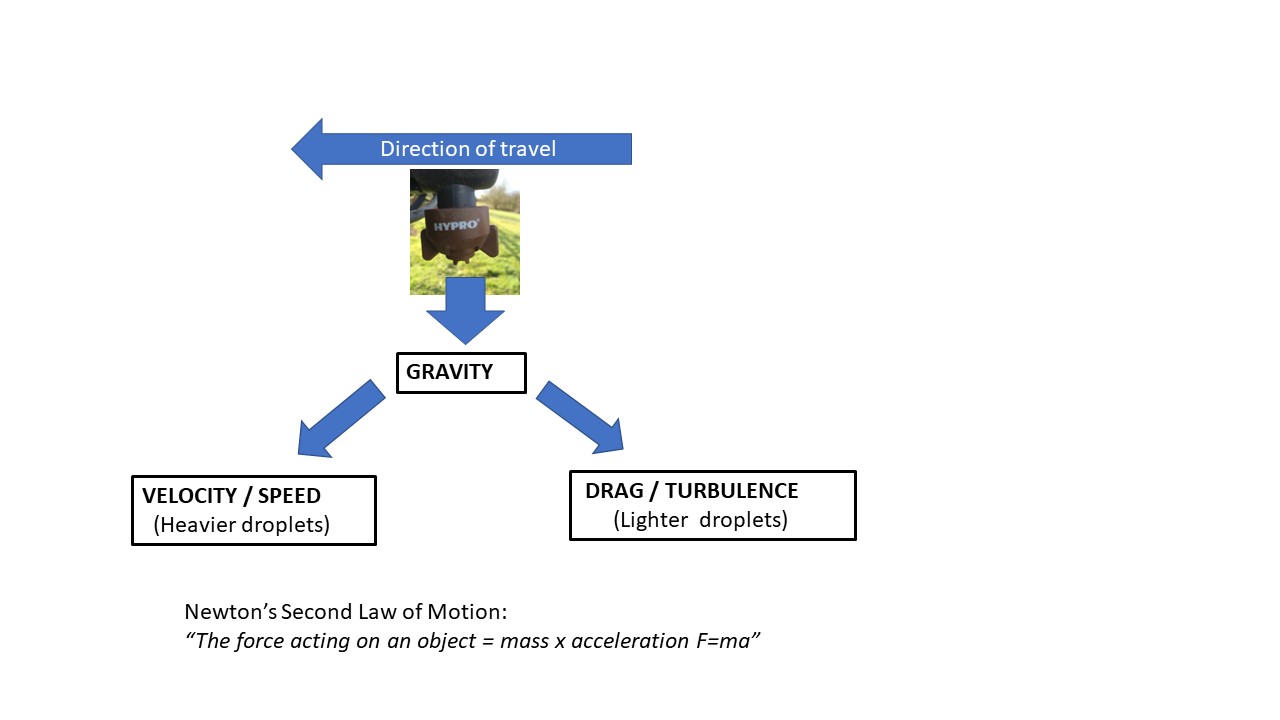

Forces acting on spray droplets

A range of droplet sizes come out of the nozzle under pressure at speeds of up to 20m/s and are then subject to external forces. The heavier the drop, the more it will retain some direction.

“You choose the water volume, which ideally should increase as the size of the canopy increases, and then select how you want to apply it by selecting a nozzle. It’s crucial to match nozzle size to flow rate so you’re operating in the correct pressure range,” he stresses.

The spray droplets are formed by pressure and the size of the orifice in the nozzle. A range of droplet sizes speed out of the nozzle under pressure and are then subject to external forces. The heavier the drop, the more it will retain some direction, he says.

“A fine spray quality produces a larger number of small droplets which increases coverage of the herbicide on the soil surface but also increases the potential for droplets to drift,” he explains.

So according to first principles, small droplets will hit the highest number of soil particles and a higher water volume will achieve best coverage of the canopy, which at the pre-em timing is the overall surface of the soil.

“In practice a water volume of 200 l/ha offers the best compromise between work rates and getting the best out of the pre-ems being applied. I prefer a flat fan angled nozzle to an air induction nozzle as one of the components of success in delivering a pre-em herbicide is the number of spots on the target,” he adds.

That goes against the trend towards low-drift nozzles and David explains why. “Blackgrass programmes are now reliant on a stack of residual herbicides applied within a relatively short period during the autumn. If you’re depositing large blobs of residual product through a coarser spray then there’s an increased risk of loading around plants and potential phytotoxic effects.

“One of the main strategies of cultural control for blackgrass is crop competition and the last thing you need is a crop that’s been knocked by herbicides in a high blackgrass population. Phytotoxicity isn’t something that’s talked about much but can be very apparent in some seasons, particularly after a prolonged dry period where herbicides are applied which is then followed by rain,” he says.

David also believes there’s more leeway to use flat-fan nozzles than you may think, provided boom height is well controlled. “Agrii trials investigated three nozzle types; a standard flat fan, an extended range flat fan and a low-drift air induction nozzle. At 50cm boom height there was very little difference between the nozzles under optimal spraying conditions.”

Engineering the water used to deliver the herbicide is one way to counter the obstacle of keeping small droplets on target, explains David. “We’ve had Backrow in our trials for nine years and have seen an average 9% increase in herbicide efficacy at the pre/peri-emergence timings. The extra blackgrass control equates to 0.45t/ha yield in a 500 heads/m2 blackgrass population, which for the £3.50/ha cost of Backrow is a good margin over input cost,” he comments.

So how is the addition of a drift retardant helping herbicide efficacy to this degree? It’s an indirect effect because Backrow has no herbicidal activity and there are very limited implications of drift for herbicide efficacy, says Dr Clare Butler Ellis, research manager at Silsoe Spray Application Unit.

“Only a very small proportion of the spray applied in a field is completely lost to drift. The most noticeable effect from using low-drift technology is likely to be a more even distribution of spray over the treated area because the spray will be much less affected by air currents, such as the wind or the wake created by the sprayer.”

In 2018, Interagro commissioned a study with Silsoe Spray Applications Unit to explore the potential reduction in spray drift by adding Backrow at 0.2 l/ha to the widely used pre-em herbicide Liberator (flufenacet+ DFF) at 0.6 l/ha. Measurements of droplet size were made in the spray lab using an 03F110 flat fan nozzle at a water volume of 200 l/ha. The results showed Backrow reduced the volume of spray with droplets smaller than 100 microns, which are most susceptible to drifting off-target, by 27%.

“The result was statistically significant and the main benefits of the change in droplet size which comes from adding Backrow to the tank mix will be reducing drift and improving the uniformity of distribution. But where nozzles are used for drift reduction, we’re usually looking for reduction levels of 75% plus, so 27% is not going to be seen as hugely significant in that sense,” comments Clare.

So with the degree of drift-reduction alone not fully explaining why Backrow has consistently improved herbicide performance in the field, does its effect on the full spectrum of droplet sizes help explain the phenomenon?

“Backrow has the ability to glue together the smallest spray droplets and split apart the largest ones so acts at both ends of the spectrum, increasing the number of droplets in the mid-range and giving a more predictable, uniform spray,” says David. The improved deposition on the soil surface means more germinating weeds come into contact with the pre-em herbicides at emergence, which helps account for the increase in efficacy seen in trials.

But there are also other factors to take into account, with weather being a prime influencer of residual herbicide activity, highlights David. In Agrii trials at Stow Longa, Backrow has been seen to help the performance of residual herbicides at the pre and peri-em timings under dry conditions to the extent that its effect has been coined ‘rain in a can’ because it improved herbicide performance in the dry to a similar level as rain.

“Half the trial was irrigated to simulate rainfall and a pre-em applied on 25 Oct, followed by a peri-em on 2 Nov. Where there was ‘rain’, blackgrass control was 89%, which was 10% better than in dry conditions (79%). The addition of Backrow improved blackgrass control achieved by herbicide alone by 7-8% in dry conditions, with 98% control achieved where there was ‘rain’.”

Backrow also helps retain herbicides in the top 5cm of soil, the blackgrass germination zone, for up to 8 weeks. This has the benefit of extending herbicide activity while reducing the risk of herbicides getting into water and the risk of herbicides moving into the rooting zone of the crop, resulting in phytotoxic effects.

Asked which herbicides in particular may benefit from the addition of Backrow, David says even the better formulated products, such as Liberator and Movon (flufenicet+ DFF+ flurtamone), showed improvements in efficacy in their trials with a similar yield increase seen in Syngenta work using Liberator plus Defy (prosulfocarb).

“Using Backrow with pendimethalin would help it’s retention on the soil surface, keeping it where it needs to be.”

David says improved crop safety with Backrow is something he’s observed in a range of different crops. “We’re looking at using Backrow with Avadex Factor (the liquid formulation of triallate) where wheat is shallow drilled to try and improve crop safety. Last autumn we recorded 10% chlorosis in trials where Avadex Factor was applied alone, compared with no chlorosis where it was applied with the addition of Backrow,” he adds.

The Science behind Backrow

Interagro’s R&D consultant Robert Butselaar explains the science behind Backrow and how it works. “Backrow is an innovative adjuvant designed to optimise the efficacy of residual herbicides by reducing spray drift, improving herbicide coverage and improving herbicide retention in the soil.

“The addition of Backrow achieves a drift reduction by increasing the volume median diameter (VMD) of spray droplets, creating a more uniform droplet size. This effect means the spray will be more evenly deposited on the soil surface and a more uniform coverage is achieved.”

Most of the active ingredients found in crop protection products are oil soluble not water soluble, explains Robert. “The carefully selected emulsifiers in Backrow promote binding of the herbicide to soil particles due to their semi-cationic nature – they facilitate bridging between the oil-water-soil interface, a process known as cross-linking.

“Retention of the herbicide in the soil is achieved due to adsorption of the oil to the soil particles. Moisture will over time (6-12 weeks) release the active ingredient for absorption through the roots and shoots of target weed species increasing both the duration and level of efficacy.”

Although there are differences between the adsorption rates of herbicide actives, most will leach to some extent due to rainfall and can leach away, he explains. “Backrow has a valuable role to play, particularly from the perspective of water stewardship, and can increase the duration of weed control by keeping the herbicide in the top 5cm of soil where most weeds, including blackgrass germinate from. Field scale research in the Netherlands has demonstrated that where Backrow is applied pre-em, the leaching of subsequent crop protection products was reduced.”

Pushing Performance

At the heart of good crop production lies careful use of chemistry to protect the plant and maintain performance, right through the season. But optimising the efficacy of plant protection products can be challenging, while increasingly restrictive regulations limit just how far you can go.

This series of articles explores the science behind the use of adjuvant and biostimulant tools to help push both chemistry and crop performance, as well as increase understanding of why they’re needed and what they do. We’re setting out to empower growers and drive crops to reach their full potential.

CPM would like to thank Interagro for kindly sponsoring this article, and for providing privileged access to staff and material used to help put the article together.

Backrow is an innovative soil-acting adjuvant designed to optimise the performance of pre-emergence herbicides in a wide range of crops, improving both grass and broadleaf weed control by as much as 13%.