The Group 1 milling market is evolving, and supplying it requires a keen understanding of its needs. CPM visits a Kent seed grower to find out where the market’s heading and how to grow for it.

It appears to perform consistently across a broader protein range – that’s a real advantage to a baker.

By Tom Allen-Stevens

For seed grower John Haffenden, it’s a good sign when every single tonne of a wheat variety he’s grown is actually sold as seed. That’s what happened to his 2017 crop of KWS Zyatt, grown at High Chimney Farm, near Canterbury, Kent, and it’s one of the reasons he’s growing the same variety again this year.

“There’s a good demand for milling wheat here in the South East,” he says. “There’s clearly a strong demand for Zyatt, and it performed well on all scores at harvest. So we’re growing it again, some put it in as a second wheat.”

The farm lies 150m above sea level on brick earth sandy clay loam over chalk. “Being near the coast and on top North Downs we get a higher rainfall than most and have deep moisture-retentive soils. It means we can give a crop the best possible growing conditions.”

It’s the seed market that the 316ha family partnership has focused on. They grow 30-40ha of seed potatoes in a rotation that includes winter wheat, winter barley, spring oats, spring beans, oilseed rape and herbage seed. There’s also a 40-head beef suckler herd.

Milling wheats dominate locally and John moved from supplying local mills to growing high-grade seed around ten years ago, with a total of 41ha of Zyatt alongside 56ha of Crusoe currently approaching harvest. “Seed suits our business model and makes sure we farm properly – you need to give the crop attention to detail and have an eye for quality. It also brings a valuable premium across our relatively small arable area.”

His focus on Group 1 milling varieties makes John “Fit for the Future” – set up to grow wheat for a market with good prospects, and with a strategy for growing it that brings strong returns. But it’s not just the market demand for Zyatt that persuaded him to stick with the variety.

“One thing we noted was how well it threshed through the combine. It was a lovely sample with a specific weight of over 80kg/hl. Crusoe can give you unthreshed tips, while Skyfall stutters with its Hagberg in a difficult harvest, and tends to be very hungry if you want to attain full spec. Although we weren’t feeding it for protein, the Zyatt sample was above 13% for a yield of 10.9t/ha, which was very pleasing.”

He reckons the roots of the crop are making the most of his deep soils, retaining green leaf area and feeding the ear. “One of Zyatt’s parents is Hereford, which has a good root mass index. We do look after the soil and find it looks after the crop and keeps the green leaf area for longer –some neighbours are usually well into their wheat harvest before ours are ready for the combine,” notes John.

“Zyatt’s still a new variety, so its disease scores are holding out well. A 6.2 for septoria gives reassurance, and we haven’t seen any eyespot. What’s more we put a mildewicide on the Crusoe this year, while the Zyatt never needed one. We don’t have to prioritise it for spraying and you could probably scale back on fungicide, although we wouldn’t risk it.”

This year, there’s 16ha grown as a second wheat. It was established following a non-inversion tillage regime that sees the straw incorporated with a Väderstad Carrier directly behind the combine and then, prior to planting a Väderstad Topdown. A 4m Väderstad Rapid put the seed in the ground in the third week of Sept.

“One thing we’re doing differently this year is putting on more trace elements. We applied Maniphos in the autumn, which gives the crop phosphite along with manganese and sulphur. We also applied Nutriwise PK Plus particularly for the phosphate as we were concerned the cold soils this spring may not release it,” notes John.

This year, an application of 250kg/ha of ammonium sulphate (N 21:60 SO3) provided the sulphur in front of three splits of Nitram. “Being a seed crop, we don’t bother with a foliar N application.” This year all the fertiliser has been applied as a solid as the farm is generally moving away from liquid fertiliser to minimise the risk of scorch.

“We’ve been careful with the Zyatt to get it going early in the spring. That’s particularly important this year with the second wheat crop, so we gave it an early N dressing. We also made sure the crop had its T0 fungicide.”

The 2018 crop looks good and John has high hopes for this harvest. Long term, however, he admits he’s uneasy about Brexit. “Anyone who says they’re fit for the future can’t really be sure. We’re heading for very challenging times and it does make it very difficult to plan,” he notes.

“Being a seed grower, we’re reliant on an arable sector that wants to continue buying certified seed. If wheat profitability falls, it may be that growers simply won’t grow a crop at all, as happens in other parts of the world, let alone one that needs quality seed.

“But the present challenge with growing seed is predicting which varieties will prove successful from the massive choice on offer. In our area, Group 1 milling varieties are a popular choice and millers certainly seem to be looking favourably on Zyatt, so I think it’s a useful one to have in the ground.”

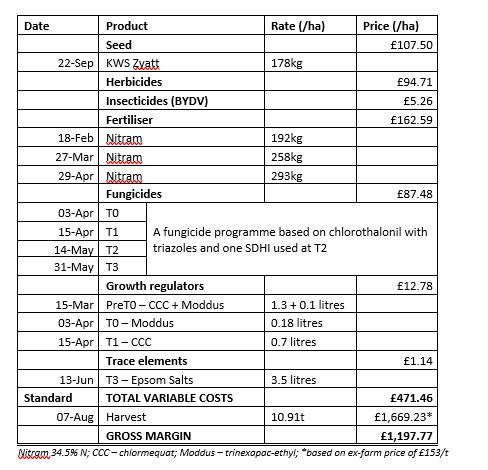

High Chimney Farm’s recipe for Group 1 milling wheat for seed, 2017

Functionality falls in Zyatt’s favour

Ever wondered what the best thing since sliced bread was? Those growing KWS Zyatt may be about to find out.

According to the Federation of Bakers, although total bakery sales have been fairly stagnant over the past few years, there’s been a 3-5 year decline in wrapped bread sales – the ubiquitous sliced loaf – while wrapped bakery snacks and breads of the world have increased in popularity.

“The wrapped bread market has buoyed over the past 12 months, and that’s certainly the case for us,” notes Rank Hovis technical director Shaun Taylor. “We’ve invested in improved quality and consistency, targeting the premium loaf market, and these products are proving popular.”

Bagels and pizza bases are among other products gaining in popularity, and that’s brought about a subtle shift in the qualities bakers are looking for from the flour they use. “It’s a more demanding process and requires a grist of higher stability and a different rheology.”

Rank Hovis has been evaluating KWS Zyatt on a mini-commercial scale, and Shaun reports that he likes what he’s seen. “Zyatt has a different quality of protein and level of functionality. It appears to perform consistently across a broader protein range – that’s a real advantage to a baker.”

So what does this mean to the grower? “In a year where there’s plenty of good quality Group 1 wheat available, it won’t make much of a difference. But it may mean Zyatt is accepted preferentially into the grist at a lower protein because the baker will have confidence in how it performs. That would favour the variety in a low protein year. Also, it may have the potential to displace imported wheat.”

It’s not just about how it bakes – tests show that Zyatt mills more effectively and efficiently than other Group 1 wheats, notes Shaun. “And it does this consistently – the consistency thing is huge.”

Gowers looking to supply the milling market with Group 1 varieties should get to know their local outlets, he advises. “Find out what sort of product they’re making, and what their particular requirements are of the wheat they’re buying.”

Foliar nitrogen should not be applied too late for all of it to be converted into functional protein, he adds. “For a baker, the quality of the product is not determined by metrics but by its functionality – the right protein level in a wheat that doesn’t perform is no good.

“And the key requirement is to deliver a consistent product. Store grain from headlands separately and aim for minimum variability across the heap. Consistency is good, and means less surprises for everyone at the intake pit,” concludes Shaun.

Local lure of the milling market

Hemmed in by the coast on three sides and with the large London mills on the doorstep, it’s of little surprise that Group 1, 2 and 3 wheats take almost the entire local certified wheat seed market, notes Andrew Bourne from Ashford-based T Denne and Son.

“Group 1 wheats make up a significant share of the requirement, and to my pleasant surprise we sold more KWS Zyatt to growers than either Skyfall or Crusoe for the 2018 harvest,” he reports.

“With some varieties, like Crusoe, there’s a relatively straightforward relationship in terms of yield and protein content that makes it a sure-fire bet for a capable grower to reach milling spec. With Skyfall the protein dilution is more difficult to predict. From what we’ve seen, Zyatt looks more like Crusoe. But it combines this with a high yield and decent agronomic package.”

The grain market for Group 1 wheats has seen a lift in recent months, thanks mainly to the effect of currency, with a weaker pound keeping imports out of the market, says Andrew. “Brexit has been slightly beneficial so far. Whether that continues to be the case remains to be seen, and changes in tariffs could have quite a dramatic effect on the local market in the South East.”

Nonetheless, there’s only a limited local feed wheat market, he points out, so growers who can achieve the spec with premium varieties will always fare better than those producing a base commodity product. “What’s more, there’s only a minor yield penalty between KWS Zyatt and some feed varieties, so growers should still receive a decent return even if the quality isn’t achieved,” he adds.

“John has always been a committed quality wheat grower, so it was a natural extension to get him on board supplying seed for us. He’s technically very focused and understands how attention to detail can make all the difference in achieving best quality. That’s important for any quality wheat grower but especially so in our part of the world where it’s our bread and butter.”

- T Denne and Son with Zantra are holding a trials demonstration day that takes place at John Haffenden’s farm at Stelling Minnis near Canterbury on 22 June. Across the plots there’s a range of Group 1, 2 and 3 wheats that have been taken through different PGR and N strategies. The event will be a chance to review four years’ results and glean how to get best from the varieties and push their premium potential.

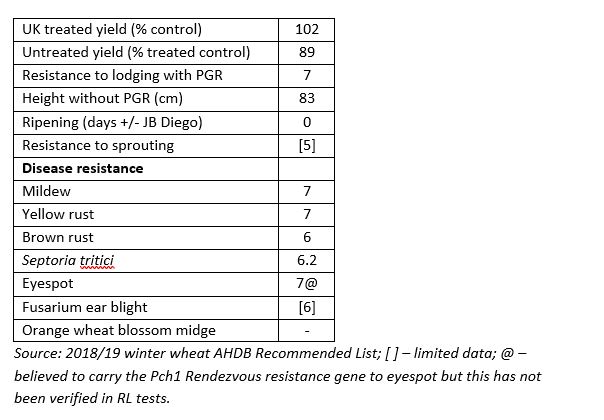

KWS Zyatt at a glance

Fit for the Future

As Brexit approaches, wheat growers will be preparing their enterprise for a market without the protection of the EU but potentially open to the opportunities of a wider world. Finding the right market, and the variety to fulfil it, will be crucial for those looking to get ahead.

In this series of articles, CPM has teamed up with KWS to explore how the wheat market may evolve from 2019 and beyond, and profile growers set to deliver ongoing profitability.

KWS is a leading breeder of cereals, oilseeds, sugar beet and maize. As a family-owned business, it is truly independent and entirely focussed on promoting success through the continual improvement of varieties with higher yields, strong disease and pest resistance, and excellent grain quality. We’re committed to your future just as much as you are.