What effect on septoria will there be next season from the loss of approval for chlorothalonil and two new active ingredients? CPM travels to Ireland to learn the lessons from this year’s trials.

Growers need new chemistry, but just how long that lasts will depend on how it’s used.

By Tom Allen-Stevens

When someone says it’s been a “good year” for disease, it can be difficult to know whether that means a good year for the cereal disease itself or for the growers who suffer from it.

When it’s senior pathologist at Teagasc Dr Steven Kildea who says it, with almost a hint of relish, you can be pretty sure it’s not going to be good news for growers. “Towards the end of June, I’d have said it was a low year for disease, but the weather we’ve had since has put it at moderate,” he says.

Oak Park research station near Dublin is a part of the world where pressure from septoria reaches its zenith.

“Couple that with good early crop growth, difficulties with the timing of the leaf three fungicide application, and yes, it has been a good year for septoria.”

Steven’s been keeping a careful watch on Septoria tritici populations at Teagasc’s Oak Park research station near Dublin, Ireland. It’s a part of the world where pressure from the disease reaches its zenith, and this has profound implications for how the disease develops, the pressure it puts on crops and the fungicide programmes set against it.

“We’re currently seeing about 80% resistance in the septoria population to SDHIs. Resistance to azoles is about as evolved as you’ll get, with only about 30% eradicant control. Together in a programme you can achieve about 65% control, and chlorothalonil (CTL) brings this up to 85%,” says Steven.

“Growers had reached a cliff edge on disease control, and CTL kept them from tumbling into the abyss. With the removal of CTL, that puts them right back teetering on the brink again. They need new chemistry, but just how long that lasts will depend on how it’s used.”

Steven believes growers are entering a third phase in the evolving story of septoria resistance. “At first it was the strobilurins – we were told septoria would never evolve resistance to them, and lo and behold they completely broke. Azoles and SDHIs have proven a very strong combination, and there’s been a change in understanding about how best to use them to maintain their efficacy, bringing in multi-site chemistry.

“Now we’re moving to another level, and we don’t have the perfect answers on how to maintain control. It’s not just about alternating and mixing. It involves more than bringing in a new mode of action. If growers want to keep a lid on septoria, this will require a whole step change in approach.”

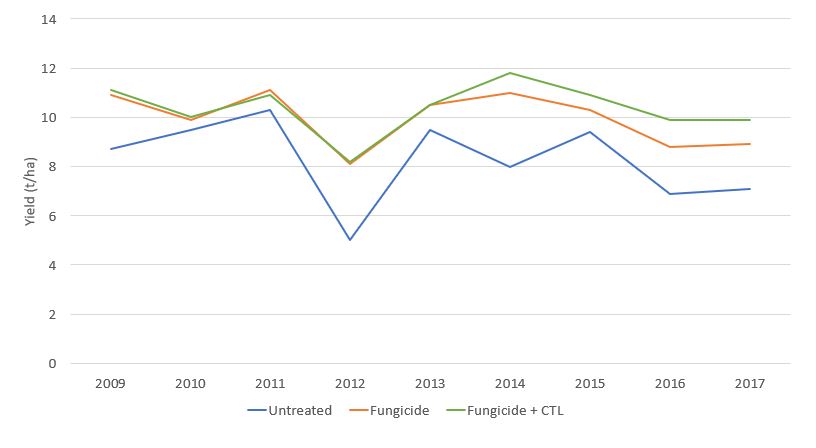

Contribution of CTL to fungicide responses

Source: Teagasc

There’s no doubt the new chemistry will prove effective, he says – both Revysol, the new azole from BASF, and Inatreq, a new mode of action for cereals from Corteva,

have been in trials at Oak Park. “They’re good, but how long will they last in current fungicide programmes, let alone without CTL?

“There are other multi-sites, such as folpet and mancozeb, but neither are as effective as CTL. What’s more, even with CTL, we’ve noticed the efficacy of the best current fungicide programmes slipping away over the past five years.

So with CTL dropping out of the picture in May next year, what does Steven recommend for this new approach? “From a pathologist’s point of view, I’m looking forward to next year. Yes, we’re losing CTL, but we’re gaining two new actives.

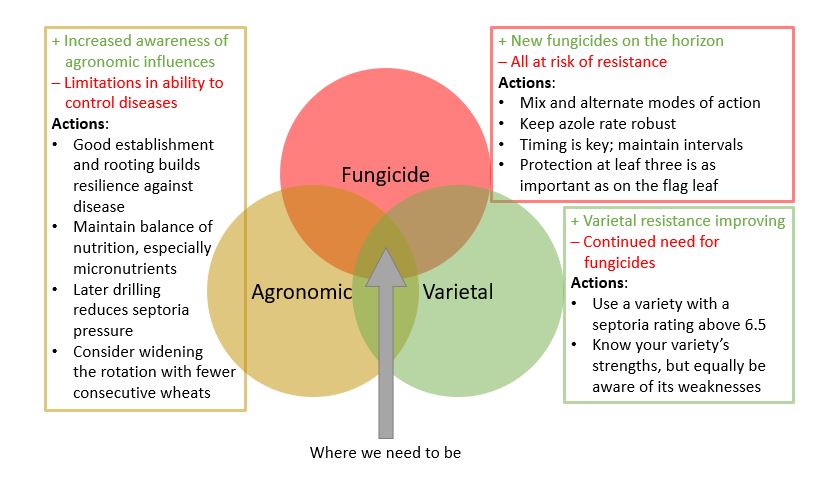

IPM actions to preserve varietal resistance and novel fungicides

Source: Teagasc, 2019

“Growers have been blessed with a succession of low disease years, but next year will be the season they’ll enter the third phase of disease control, and it’ll involve every element of integrated pest management (IPM).”

The first step is variety choice, he explains. “You could look at the variety’s resistance ratings as the new multi-site. Even if it has a 2t/ha yield penalty on paper, that’s better than losing 3t/ha to disease. What we don’t know yet is what effect that will have on selection within the septoria population, however it’s something, alone and in combination with the alternatives to CTL, that we’re investigating.”

In Ireland, JB Diego and Bennington are the go-to varieties of choice at present, but disease scores set certain varieties a considerable distance from others, and Steven reckons wheats of choice are set for a change. “Yellow rust has come in this year – a relatively uncommon disease in Ireland. It’s made many growers question their variety choices, and I think we’ll see a distinct shift towards those with a more robust disease score.”

When it comes to fungicide use, timing is the factor Steven highlights, and one that he feels has come to the fore this year. “So long as you use SDHIs and azoles at both fungicide timings, apply them at the right time and use CTL, you’ll be OK. Lose any one of these, and particularly miss the correct timing even by a few days, and you’re in trouble. So with no CTL next year, the right timing will be critical.”

For this reason, he prefers to talk about timings in terms of plant growth stage and leaf emergence rather than T numbers. “From a septoria point of view, you don’t get much benefit from the late tillering application, provided your timings are right later on. Rust is a different beast and may need managing at that time.

“I view the leaf three and flag leaf sprays as of equal importance, however. This year, the leaf three timing demanded a robust dose rate – 80-100% – and when it comes to choosing where to put the new chemistry next year, either timing would suit well in terms of getting the best results.”

But what’ll make the difference next year, and will help protect the new chemistry as well as keep septoria populations in check, will be general crop agronomy. “A crop that gets off to a good start and is then looked after diligently throughout the season will stay healthy and fight off disease. Consider the entire process of growing the crop, from planting to harvest, in building crop resilience and taking the pressure off fungicide chemistry and varietal resistance.

“Revysol is currently effective against all known septoria mutations and will offer a step up in efficacy, but for how long? Ensuring its longevity, as with all other chemistries is essential and key to achieving this is to use them responsibly, only where required and at the minimum doses required to maximise disease control, yield and profitability,” Steven stresses.

“It could of course be argued that the best resistance strategy is not to use them at all. Realistically, though, they provide much needed solutions to our current disease problems. However they are only part of the solution and it’ll be the entire crop production programme that counts and will bring best results for the most seasons,” he concludes.

Revysol reveals its strengths

It’s somehow fitting that the tour of the Revysol trial plots at Oak Park are conducted in a hazy stream of rain – a reminder of the wet conditions in this part of Ireland that push fungicide programmes to their limits.

“Ireland is always the first to experience problems with septoria resistance, which is why we’ve been keen to explore Revysol in a number of different programmes and situations and see how it compares with the industry standards,” notes BASF’s Tim Short.

Revysol (common name mefentrifluconazole) is an isopropanol-azole that has just been authorised for use in Europe and will be available for growers in the UK for spring 2020. It’s the first of a new class of azoles, according to BASF, and the first major azole to achieve product authorisation since prothioconazole in 2002.

“Getting Revysol to market has involved a complete change of mindset for us,” explains Tim. “We turned on its head the normal method of discovery. We were not just looking to optimise efficacy against fungal pathogens. In parallel, we wanted to create a product with a favourable regulatory profile and needed to anticipate the regulatory environment it would encounter. The fact that it’s been approved in today’s highly challenging environment is a phenomenal achievement.”

It’ll be sold as a co-formulation with BASF’s leading SDHI Xemium (fluxapyroxad), subject to successful authorisation, for use on wheat and barley for the control, principally, of septoria in wheat, ramularia in barley and the rust diseases in both crops.

So having overcome the regulatory challenge, how does the new azole fare on the efficacy front? BASF’s Steve Dennis is on hand to guide us through the plots. “The difference with Revysol is the way it is still able to bind to mutated CYP51 enzymes. This blocks a vital part of the process for membrane development in septoria, leading to the pathogen’s death. Combine this with rapid uptake and long-lasting activity and we have highly effective septoria control. Revysol looks to have a similar effect on yellow rust as prothioconazole, while it’s a little better on brown rust,” he summarises.

The plots pitch 752 (code name for the Xemium/Revysol co-form) against Aviator (bixafen+ prothioconazole), Ascra (bixafen+ fluopyram+ prothioconazole) and Elatus Era (benzovindiflupyr+ prothioconazole). These are compared in a standard programme including the SDHI co-form at both leaf three and flag leaf timing, on the winter wheat variety Lumos, which is fairly susceptible to septoria.

“Where 752 was applied to the flag, in every case the leaf is cleaner with clearly fewer septoria lesions than with any other co-form sequence used,” says Steve. “The difference where it’s used at leaf three shows up through the full length of the leaf canopy, with more of the upper leaves retaining green area, which has indirect benefits for the flag.”

Steve recalls the tours of the BASF trials he conducted at the launch of epoxiconazole in 1994. “When Opus was launched, everyone said it was a flag-leaf product. But with 752 we have something that’s far more flexible, with clear improvements over the current standards at either timing.”

Further trials have tested the rival products in a delayed situation. Here, the crop received no leaf three fungicide and the flag leaf spray was delayed by a week and then a fortnight beyond the optimum date. “It’s the nightmare question – ‘how late can I go?’,” says Steve.

752 delayed by seven days appears to deliver slightly more efficacy than a well timed Ascra application, while stretched to 14 days it brings a similar level of control to a spot-on application of Elatus Era, notes Steve.

“It’s interesting to know how products fare when timings are stretched, and where delays are unavoidable the impact where Revysol is used is much lower. But Revysol works best when used correctly and the opportunity is to progress by improving control. We’d never recommend stretching timings as that puts the products under increased pressure.”

And it’s the stewardship aspect Steve is keen to reiterate. “Just like Opus, Revysol is no silver bullet. Its usefulness will depend directly on how growers look after it.”

Tim echoes these comments. “We all know the stewardship guidelines to protect the chemistry, so there’s no excuse for a breakdown in activity. Work starts now to build a strategy that will give growers sustained robust protection from septoria in 2020, and it involves bringing in all the tools in the IPM toolbox.”

Ramularia key threat in barley

With barley, there’s a different set of challenges, notes Steven. “The prospects with the crop are slightly better as we currently have four modes of action with efficacy on most of the main barley diseases. But ramularia is a real problem, and it’s a complicated disease.”

In Ireland, more barley is grown than wheat – currently spring barley is the most widely grown cereal at 100,000ha, with winter barley at about 80,000ha and wheat trailing behind at 60,000ha.

“Straw is really important for the livestock producers here. The challenge of septoria is making wheat an expensive crop to grow, and barley can be more profitable. You don’t really get break crops, though,” notes Steven.

Chlorothalonil has become the essential fungicide for ramularia, he says. “CTL sets the standard for control in the crop – folpet has some control but it’s not CTL. The SDHIs no longer bring much control. Prothioconazole does something, although not as much as three years ago. Revysol comes somewhere above prothioconazole.”

Work is under way at Oak Park to find alternative solutions to help keep ramularia in check. “We’re finding winter two-row feed variety KWS Cassia provides a lot more tolerance to the disease, although it comes with its own problems in terms of rhynchosporium and net blotch.

“As a disease that’s brought on by stress, better agronomy in barley may help and we’re looking into the use of biostimulants to give the crop more resilience. We’ve one year left with CTL, so hopefully we’ll have answers in time for when we lose it altogether,” says Steven.