Xemium was launched with one of the biggest marketing campaigns for a fungicide seen in recent years, but what gave BASF such confidence in the product and took it to market leader? CPM tells the story.

When we took people into the field, what they saw hit them between the eyes.

By Tom Allen-Stevens

Xemium was launched with a marketing campaign would have left few growers in any doubt about its potential to be a leading fungicide.

These days, an innovative addition to the chemistry toolkit is a relatively rare occurrence. It makes the introduction of a new fungicide not only significant, but truly a landmark event.

When BASF launched Xemium (fluxapyroxad) in Oct 2011, it was given the fanfare warranted by just such an innovation. A broad-spectrum SDHI fungicide, positioned at the main cereal timings, the potential market was huge and Xemium’s marketing campaign would have left few growers in any doubt about its suitability.

“We were really very excited about Xemium,” recalls BASF crop protection field sales manager Steve Dennis. “It was very clear early on that we had something quite special. Its potential wasn’t just big in sales terms – Xemium had a real technical edge, and that sort of product doesn’t come round very often.”

What was exciting the sales team was how Xemium was performing in pre-launch trials. “It was doing something to the crop that, at that point, you just couldn’t explain, but the difference over standard strobilurin/triazole-based programmes was very obvious. Although we couldn’t reveal too much about the material, we couldn’t resist taking people into plots to give them a sneak preview, and they were equally amazed.”

Xemium is now sold worldwide with approvals on over 100 different crops. In 2013, it received the BASF Innovation Award for a product across the company’s business that has achieved outstanding results, and in the same year BASF increased the peak sales potential for Xemium by €200 million to more than €600 million.

In the UK, Adexar (fluxapyroxad+ epoxiconazole) is now established as the biggest SDHI product applied to wheat at the T2 spray timing. In independent trials conducted by SRUC, NIAB TAG and ADAS, Adexar and Librax (fluxapyroxad+ metconazole) have yielded an average of more than 0.2t/ha over Aviator (bixafen+ prothioconazole) across 73 comparisons from 2014 and 2015, delivering an average margin benefit of £20/ha.

Original SDHI

So where did this innovation originate? “The story for this group of chemistry started some decades ago,” explains Markus Gewehr, who led the research team for Xemium at the BASF R&D headquarters in Limburgerhof, Germany.

“The carboxamide benodanil was used as a seed treatment, while in 2004, boscalid was introduced for use on oilseed rape, cereals and speciality crops.” The chemistry works by blocking the activity of the succinate dehydrogenase enzyme within the mitochondria of the fungus. These are the fungal energy factories, and without the enzyme, the mitochondria can’t function and the pathogen shuts down.

“Boscalid is good, but its activity is limited in terms of the pathogens it will control. But we were convinced there was greater potential to these SDH inhibitors, so in 2001, a new research project started looking for a new active ingredient. Our chief targets were septoria and Asian soybean rust,” he recalls.

More than 1100 analogues were synthesised by the research team and most of these were taken to small pot tests in the lab and field trials. Sure enough, there was one particular molecule that surfaced with outstanding activity against septoria.

“It came initially as a complete surprise,” continues Markus Gewehr. “Previously our work with SDHIs had shown they were only active at the very early stage of the pathogen’s life cycle, yet here we had a molecule with far stronger performance at the later stages. We needed to know more about this remarkable discovery.”

There were hints that this novel efficacy was down to mobility. “It was behaving differently to other SDHIs in how it reacted to different substrate within plant tissue.”

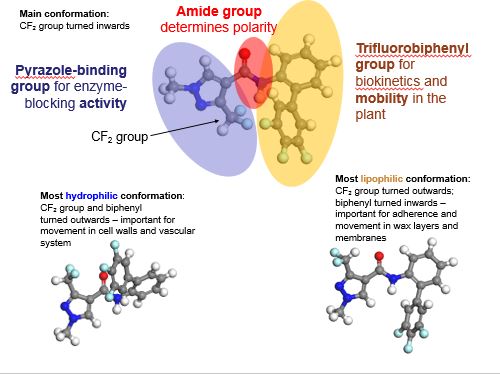

What they discovered was that the molecule changed its conformation (see panel on pxx). This depended on whether it was moving in the wax layers of the leaf and through membranes of the fungi, requiring a lipophilic conformation, or travelling through the water-based cells, walls and vascular system, where a hydrophilic combination was better.

Polar performance

“The different conformations change the molecule’s polar properties. The most polar part of the molecule is the amide group, and this can be shielded by other parts of the molecule, making it lipophilic, or exposed, reducing the lipophilicity by around 100 times,” explains Markus Gewehr.

Molecule mobility – Xemium adapts its conformation

“It means Xemium can move smoothly between lipophilic and hydrophilic environments within plants and fungi. This is unique, and we realised it was this mobility that was delivering the molecule rapidly to its target site with such efficiency.”

The next step was to develop a formulation to carry the active ingredient, notes BASF European technical manager Dieter Strobel. “We’d made a lot of progress with the development of Brutus (epoxiconazole+ metconazole). This know-how we transferred into Xemium and the resulting formulation ensured quick and complete coverage of the leaf surface and further improvements in mobility.”

The combination of its inherent mobility and its formulation gives Xemium systemic movement through the leaf, while its lipophilic property ensures it’s taken quickly into the leaf’s wax layer and is rainfast, he adds. “However, we found 70% of the applied active stays in the wax layer and forms crystal-like depots that prolong the activity of the chemistry.”

The scientists realised it was Xemium’s unusual mobility that was delivering the molecule rapidly to its target site with such efficacy.

The dossier for Xemium was submitted in 2009 – just five years after the initial discovery was made – and the product was launched in Oct 2011. “It normally takes ten years to bring a new active to the market, but Xemium was developed in less than eight years,” notes Dieter Strobel.

The plan was to introduce Xemium to the market over several seasons prior to the launch in the UK, recalls Steve Dennis. “When we took people into the field, what they saw hit them between the eyes – they were completely blown away by the standard of disease control compared with what they’d seen from a strob-triazole mix.”

The trials results were also showing a solid performance, with 2011 wheat trials at Teagasc delivering a 0.6t/ha yield benefit over Aviator. In barley in ADAS trials it gave a 0.3t/ha advantage over Siltra (bixafen+ prothioconazole) in trials where rhynchosporium was the target, and it equalled Siltra’s performance on net blotch.

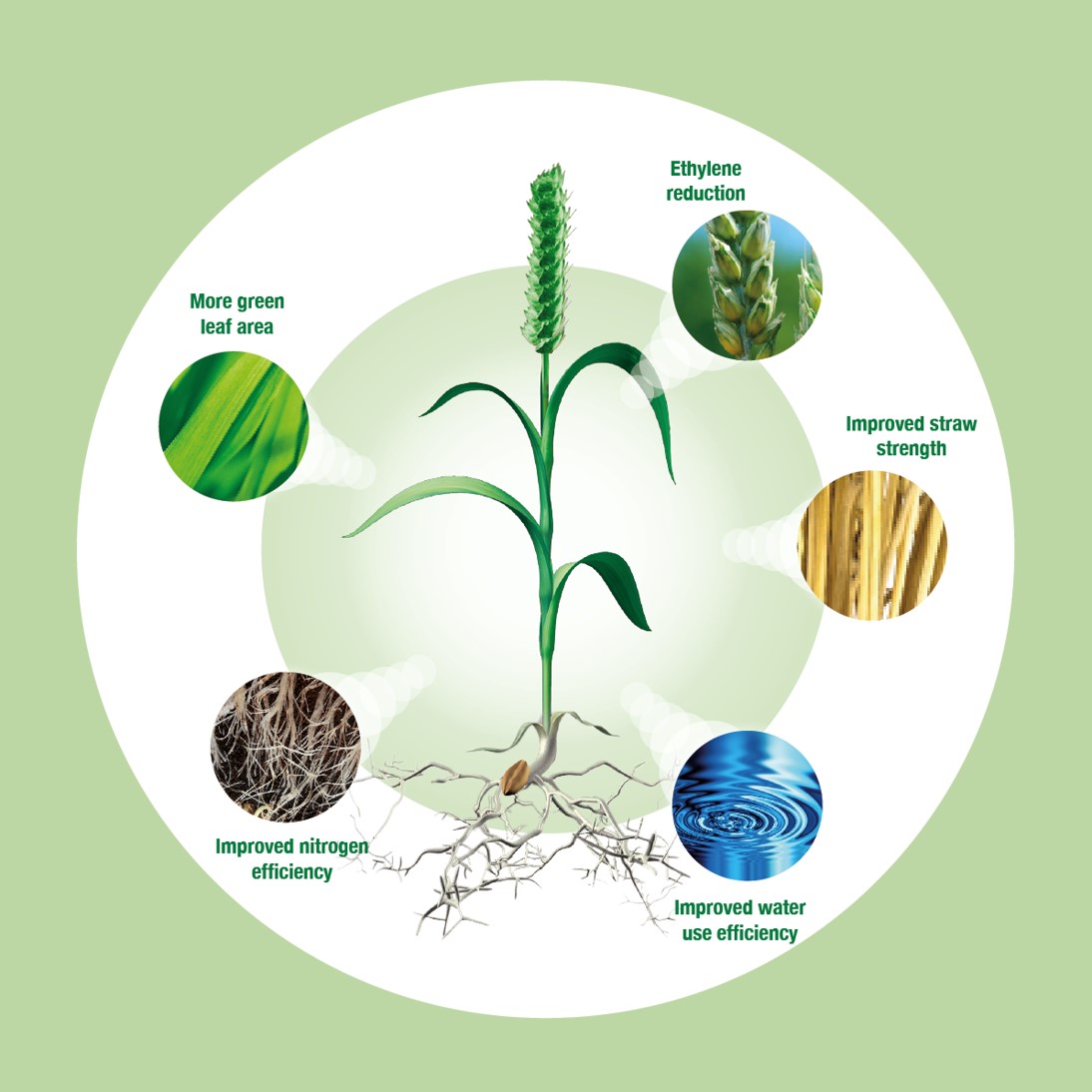

“The yield responses were good, but it was delivering these even in the absence of disease,” notes Steve Dennis. “We were keen to explore some of the properties that we were seeing in the field – what was the greening doing to the plant? Was there a difference we could measure for nitrogen and water-use efficiency?”

BASF asked ADAS to investigate these properties – a three-year project was led by Julie Smith. “I’d seen Xemium in trials, and was aware this was a very strong product. But like any scientist, I was sceptical of these greening claims,” she says.

“We set about establishing first whether there were yield benefits above what could be explained through just disease control, and if there were, exactly what was going on. To be robust, these had to show under field conditions.”

Trials were set up to measure healthy area duration (HAD). Previous research had established this as a robust method of quantifying the green leaf area over time, from ear emergence to canopy senescence, which could then be related to yield.

BASF was were keen to explore some of the properties seen in the field, such as greening and water-use efficiency.

“We just looked at Xemium, compared with untreated, and wheat treated with epoxiconazole, boscalid and pyraclostrobin – no other new SDHIs were tested. But we found there was an additional yield, of around 1t/ha, which was a surprise.”

Not only did the crop canopy stay greener for longer, it was a deeper green, she adds – a SPAD meter confirmed this. “Under the microscope, we found there was less cell damage to plant tissue treated with Xemium compared with other treatments.”

Most striking results

But water use efficiency tests proved to be the most striking, she recalls. “We measured stomatal conductance – the amount of water vapour the leaf surface loses. Xemium-treated crops have a lower stomatal conductance, and this result was very consistent. While an untreated crop needs 380t of water per tonne of grain on average, one treated with Xemium needs just 300t.”

Further trials showed Xemium had an effect on septoria at every stage of its life cycle. “Significantly, this includes good activity during the latent period. This results in a longer latent period, having the effect of slowing down resistance by reducing selection pressure,” notes Julie Smith.

“We also measured septoria ascospore populations in the winter between two successional wheat crops. Where the first crop was treated at both T1 and T2 with Xemium, spore numbers were lower and disease severity less in the following crop.”

Below ground, Xemium also appears to have an effect on rooting. In trials carried out at Brooms Barn, wheat in polytunnels was subjected to extreme drought. Those treated with Xemium had 50-60% more root growth at 1m depth, and up to 10% more chlorophyll in leaves.

“We don’t fully understand why Xemium has this effect, and the result isn’t always consistent. But it does have a beneficial influence on a wheat crop and it’s an effect you can measure,” concludes Julie Smith.

Meanwhile, Xemium has now been partnered with metconazole in Librax, a product that has equalled or even improved on the control offered by Adexar in 2015 AHDB Cereals and Oilseeds fungicide performance trials. Dieter Strobel puts this down to formulation, again. “We’ve had an extra two years to refine the formulation and the result is a product in which the uptake of the metconazole is optimised – the two ai’s perform better together than they’d each contribute on their own.”

Librax fits well at the T2 spray slot, he says, where the timing may have been delayed bringing in the chance of disease, particularly on lower leaves. “The broad spectrum of Adexar, and its strength on eyespot make it a good choice for the T1 timing.”

There’s further innovation to come, he assures. BASF has recently unveiled a new triazole Revysol. Although no new triazole has been brought to market for over ten years, the new fungicide, recently submitted for registration, has been designed to meet both “the highest level of regulatory standards and outstanding biological performance”, claims the company.

“Librax is far from the last product you’ll see from the Xemium family – we have a very strong discovery pipeline and you shouldn’t underestimate what can be achieved with a targeted optimisation of the tweaks in formulation,” notes Dieter Strobel.

“What started as a quest for another SDHI evolved into the leading fungicide for cereal disease control. Xemium’s set to retain that position for some time to come.”

Robust treatments needed against septoria and rust

Variety choice and a robust fungicide treatment form cornerstones of a strategy designed to keep disease in check for Ron Gabain, who manages the Stetchworth Estate near Newmarket. “Septoria is always our primary target together with rusts and eyespot,” he notes.

“Already we’re seeing both septoria and rust in the bottom of the crop, as a result of the mild winter conditions, and we need to make sure we keep on top of these diseases as they’re more difficult to cure and easier to protect against.”

The Stetchworth Estate has 1200ha of arable crops on soils split roughly one third heavy and two thirds medium, all over chalk. On the heavier chalky boulder clay, winter wheat, spring barley, linseed and beans are grown and on the lighter land sugar beet, spring wheat and peas come into the rotation

This year, Ron Gabain is growing 200ha of winter wheat and 100ha of spring wheat, some of which is late autumn drilled where conditions allow. He chooses his varieties carefully so that they bring good disease tolerance into the strategy. “Otherwise you increase the risk of a serious disease outbreak if the weather breaks down,” he notes. So Skyfall is one of the wheat varieties grown, while Crusoe and KWS Lili also have a suitable disease profile, he says.

Following a mild winter with a lot of over-wintering septoria inoculum, he’s concerned that warm wet conditions with rain splash could cause the disease to spread rapidly in the spring. “If you don’t keep on top of it, without a robust strategy in place you could be fighting a losing battle.”

So he feels there’s a strong place for SDHIs in his fungicide programme and, while there are a number of good SDHI products available, has chosen Xemium over the rest. “I think Librax and Adexar probably have the edge. The metconazole in Librax complements the Xemium and helps with the rust, septoria and eyespot control.

“In particular metconazole has a good profile on rusts and I think it may be least affected of the triazoles by resistance in septoria. So the combination of Xemium and metconazole in Librax works well together.

“I use Adexar at T1 as it partners one of the best SDHIs with one of the best triazoles, epoxiconazole, particularly against rusts. I find that a low rate of a morpholine can be helpful in the control of rusts and mildew too.

“At the T1 timing I’d start with Adexar plus chlorothalonil. This is followed up approximately three weeks later at T2 by Librax and chlorothalonil with the objective of keeping out septoria on the flag leaf.”

Ron Gabain is well aware of the SDHI septoria resistance reported recently, but the way he uses SDHIs in his programme is consistent with the FRAC guidelines of just two SDHI applications per crop and in coformulations and tank-mixes with multi-site fungicide chlorothalonil.

The Farm has hosted a number of independent and manufacturer’s trials over many years. This brings Ron Gabain, who does most of his own field walking, valuable experience and knowledge of a range of products. “I’ve chosen to use Xemium fungicides because I believe them to be one of the best performing. I’ve seen excellent trials results and I expect the best yields and the best disease control from Librax and Adexar,” he adds.