For many growers, it’s the burden in the seed-bank that poses the biggest threat from blackgrass. CPM joins the Task Force engaged in helping one Shrops grower put a plan in place for his spring barley.

Andrew’s clearly managing the population well, but he’s on a knife edge.

By Tom Allen-Stevens

Glance across one of Andrew Williamson’s fields of wheat or spring barley and you’d think he doesn’t have an issue at all with blackgrass. But that’s not how he sees it.

“It’s managing what you can’t see that’s critical for me – the blackgrass that’s in the seedbank,” he says. “You walk a field and you may come across only three or four plants, but that’s only because there’s a population being actively managed.”

His aim is a blackgrass policy that keeps the arable cropping profitable and sustainable. “We’ll never get to 100% control, but I’m also aware that we’re never more than a season or two away from a serious grassweed problem that’ll take over, so we can’t afford to let things slip.”

Andrew farms 320ha of silty clay loam soils based at Upper Overton Farm near Bridgnorth, Shrops. A “fairly standard” combinable crop rotation has seen spring crops – mainly barley and beans – take a greater share of the undulating land alongside winter wheat and oilseed rape.

Cover crops are used ahead of spring crops to keep soils that are prone to slumping in good shape and active, prevent erosion and present land that’s reasonably dry and ready to drill in early spring.

It was the drive to improve the soils that also led to the purchase of a Sky Easy Drill in August 2018 and an unsteady move towards direct drilling. “We do as little cultivation as we can and as much as we need to,” he explains. “We can get a pan at 100mm depth and the top 50mm is prone to slumping. So we still have the Väderstad Rapid with a toolbar for where it’s needed.

“But where we can, we’ll drill direct – in autumn 2018 it worked brilliantly, but the Sky drill might just as well have stayed in the shed last autumn. I was always aware it would be a learning curve, but didn’t expect a cliff edge.”

For some time, Andrew’s blackgrass policy has been to implement a number of cultural measures alongside herbicides to keep a firm lid on populations. But is this policy keeping pace with the gradual change in system and soil-improvement programme? That’s where Bayer’s Blackgrass Task Force is stepping in to help out.

Upper Overton Farm is one of two that have become the focus of field trials and monitoring work undertaken to translate research and understanding of blackgrass into strategies that can be successfully implemented on farm. The Task Force is led by Bayer herbicide manager Ben Coombs with NIAB’s John Cussans providing specialist grassweed advice and Philip Wright of Wright Solutions giving insight on cultivations and soil management.

“Blackgrass is still top of the tree as the number one agronomic problem on many UK farms,” Ben explains. “Most growers are moving to integrated control programmes, but there’s a lot of potential solutions, recipes and methods coming through in small-plot and field-scale trials. What we’re aiming to do is implement recommendations, specific to typical commercial field situations, and unearth the story on successful blackgrass management.”

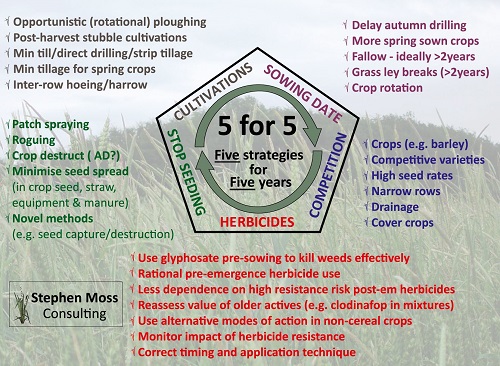

Source: Stephen Moss Consulting and Tom Allen-Stevens, 2017.

Ben stresses that these are recommendations, with Andrew remaining the decision maker, and the focus field is a commercial crop, not a trial site. “It’s a team effort – the difference here is that Andrew has resource and knowledge he can draw on to help him make the best-informed choice.” As far as possible, this is being framed around Stephen Moss’ 5for5 approach for managing blackgrass. This encourages growers to adopt five different control strategies, only one of which is based on herbicides.

The field in question is currently in spring barley, following winter wheat last year and an overwinter cover crop of spring beans, phacelia, buckwheat and vetch. It was then sprayed off with glyphosate on 23 March and drilled six days later. Blackgrass plant counts were taken in early May, with head counts assessed in mid June. In addition, a representative soil sample of the top 25cm was taken in 5cm layers and weed seeds counted to assess the background seed-bank population.

One small triangle of the field, known to be a bad blackgrass patch, was left uncropped, and sure enough, that’s where most of the plants were found. A 3ha area of crop around this was sprayed with a pre-emergence herbicide of flufenacet, pendimethalin and diflufenican on 8 April, while the rest of the spring barley remained untreated.

So what are the recommendations from Bayer’s Blackgrass Task Force?

Stop seeding

John was almost “disappointed” by how few blackgrass plants he found in the field. But it was the seed-bank assessment that revealed the true picture. “Even where there were low levels of seedlings there were hundreds of seeds in the seed-bank – what germinates makes up only 5-10% of the population,” he reports.

“This reinforces the point that as you change the footprint of the agronomy, you will alter the dynamics of this population. So the move to direct drilling will mean less seeds are stimulated to germinate at drilling, but that won’t stop others coming through in the crop.”

Blackgrass seed left buried dies in just a few years, and research has shown the population can be reduced by 99.9% over five years if seed return can be prevented. So Andrew’s ability to keep the plant population low will result in a lower seedbank, John confirms. “This is a well managed field with a good rotation and it’s typical of what we find as you move away from the heart of darkness of blackgrass. Most farmers sit with Andrew on the edge of this spectrum.”

Ben agrees. “What’s on the surface looks manageable, but the real problem lurks beneath. So Andrew’s clearly managing the population well, but he’s on a knife edge,” he says.

Blackgrass wasn’t the only grassweed found, with brome and rat’s-tail fescue also evident, notes John. “Weed management isn’t one-dimensional. The move to no-till may be encouraging other species.”

For Andrew it’s a vindication of the policies he’s put in place, but also a sign he can’t let up the pressure. The previous wheat crop was hand-rogued of the last remaining blackgrass plants and it’s a control option he uses as much as he can to keep seed return to a minimum. He’s also planning to take the uncropped corner out of production and into stewardship.

Sowing date

This is where Andrew draws a red line. “Trying to delay drilling combinable crops until the back end of Oct is too risky for us. I’d rather drill what I can in Sept and put the worst fields into a spring crop,” he says.

With around 80% of blackgrass germinating in early autumn, delaying drilling can help reduce the burden significantly, notes John. “But all farms have their practical constraints, and you shouldn’t implement something you know won’t work. It’s important to work the strategy around it to compensate, though. In Andrew’s case, he keeps his rotation flexible and puts an emphasis on trying to prevent seed return wherever he can.”

The flexible rotation is a key aspect for Andrew. “We used to have a set rotation, but it’s far more flexible now, with the worst fields for blackgrass put into a spring crop. It means you may have to move the combine an extra time, but it’s worth it for the weed-control benefits.”

Competition

The late-drilled cover crop didn’t provide much competition for the blackgrass, notes Andrew. “But for me, it’s what the roots are doing that’s more important than building what I’d call a ‘Twitter’ canopy. The main aim with the cover crop is to improve the soil and ensure it’s dry enough for spring planting.”

Philip agrees. “The main benefit from cover crops comes from what they’re doing below ground. The roots hold the soil profile together and pump water out, and a crop that looks thick on the surface may not be delivering these benefits. The roots also help to build structure as the soil shrinks and swells.”

A good structure and dry soil in early spring ensure the cash crop itself establishes well, and it’s the competition this provides that’s more important for blackgrass suppression than the cover crop, notes the Task Force team. Philip’s inspection of the barley with a spade notes a porous structure with unrestricted roots, and he concludes the cover crop’s doing its job.

Another practice suggested by the Task Force is to raise seed rates. Andrew varied the rate, with an average across the field of 440 seeds/m². The recommendation going forward is to explore this more to increase plant competition.

Cultivations

Direct drilled at the end of March, the benefit for blackgrass control here is minimum soil disturbance, notes Philip. But there are other aspects he’s keen to highlight.

“It’s important to focus on tyre pressures and the spec of the tractor – if you put a lot of pressure or wheel slip on the soil at drilling, you’ll actually encourage blackgrass, while surface compaction will prevent water getting to the roots, reducing crop competition.”

A spade inspection of the headland of the field reveals a platy structure and more compaction than in the centre. Philip recommends some targeted lifting – a grassland sward lifter creates less disturbance than a flat-lift tool. His tip here is to use the cover crop as a litmus test for where to apply it.

“As the cover establishes, this will reveal areas that may be compacted, and it can be an idea to do the lifting in the crop itself – roots with iron do a better job than iron by itself.”

Around 175-200mm depth is where this is needed, and the rule of thumb is to keep the low-disturbance legs twice as wide as the depth. “But if you have roots as well you can stretch that significantly – a real benefit of roots and metal acting together,” adds Philip.

Herbicides

With just 3ha of the field treated with a pre-em, this gives Andrew a good comparison of how it performed compared with untreated.

“It’s hard to tell how much blackgrass would have come through in the treated area, but the crop was noticeably thinner. I wonder whether a pre-em does more harm than good,” he suggests.

Ben notes that Liberator (flufenacet+ DFF) has label approval for meadowgrass and broad-leaved weeds in spring barley. “Cultural controls are the main tools for blackgrass and there is a risk of knocking the crop. But there’s a sweet spot of how best to judge the use of a pre-em and this will depend on overall weed spectrum and burden, the situation and any contact chemistry planned.”

Partners in performance

Partners in Performance is the result of a long-standing collaboration between Bayer and a group of progressive growers.

It started in 2011 with the launch of Aviator Xpro when growers were invited to trial Aviator on their farm. In these split-field trials Bayer took a back seat with the only demands being the field area for fungicide comparison and crop yield verified over a weighbridge or via combine yield monitor –– everything else was down to the farmer.

Over time this has developed into a club. Each year the farmers meet to discuss results, listen to guest speakers and debate winter wheat management issues.

Farming has always been a challenging business, and with Brexit those challenges have intensified. The margin between profit and breaking even is likely to become even tighter and any incremental gain will be needed for sustainable combinable crop production.

To achieve that the industry needs to work together to share the latest research and thinking, exchange ideas and experiences.

Partners in Performance aims to bring farmers and specialists together to develop solutions to improve crop performance and investment return.