Use of biostimulants is the fastest growing area in crop protection. CPM investigates the science behind amino acid-based product, Bridgeway, and gathers feedback on its performance in the field.

Stress is certain. It’s something crops have to deal with all of the time to varying degrees.

By Lucy de la Pasture

A new era in biostimulants is shaking off the mantle of snake oil, a legacy from years of sometimes dubiously researched products making incredible claims. But now a much-needed injection of science is increasing the level of understanding behind how biostimulants can work to promote plant health and ultimately benefit yield, explains Interagro technical manager, Stuart Sutherland.

Amino acid production within plants is hugely energy intensive, explains Stuart Sutherland, so it’s beneficial to supplement crops with amino acids to maintain growth.

“Biostimulants are substances (other than pesticides or nutritional products) that have the capacity to modify physiological processes in plants in a way that provides potential benefits to their growth and development and/or alleviate plant stress,” he explains.

There’s now a significant interest in the benefits biostimulant products can bring, believes Frontier’s Dr Paul Fogg, particularly on the back of last season when a late, wet early spring morphed into a hot, dry late spring and summer bringing evident stress symptoms to crops.

“It’s easy to notice crops are stressed under these extremes of weather but there’s a need to better understand the subtle scenarios that also create crop stress. These include periods of rapid growth when the plant can’t assimilate nutrients fast enough, large fluctuations in diurnal temperature and very bright or very dull days. All these are also stress factors,” he says.

One of the biostimulant products that’s attracting the attention of growers and agronomists is Bridgeway. It supplies the crop with all the amino acids essential for life, building blocks that Stuart believes are often one of the most overlooked assets when it comes to plant nutrition.

“From strengthening plant cells to resisting disease or breaking down nutrients in the soil and strengthening roots, amino acids are the building blocks of proteins and plant performance. Plants need protein for healthy growth and development, as we do,” says Stuart.

Understanding the role of different amino acids in the plant’s many biochemical processes may help agronomists target crops that would benefit most from the application of Bridgeway at the best time to influence their growth, comments Paul.

He also believes it’s fundamental to adopt a programmed approach by looking to build structure and root biomass early in a plant’s life. “By starting early, the plant will be more resilient to any environmental and biological stresses. You can then capitalise on that potential later in the season.”

One of the key processes that requires all 18 essential amino acids contained in Bridgeway is photosynthesis, explains Stuart. “These amino acids combine in infinite variations to produce countless different proteins. These proteins can only be made if the raw materials to produce them are present – carbon and oxygen from the air, hydrogen from water and nitrogen from the soil. Plants therefore depend hugely on soil nutrients for their protein supply.

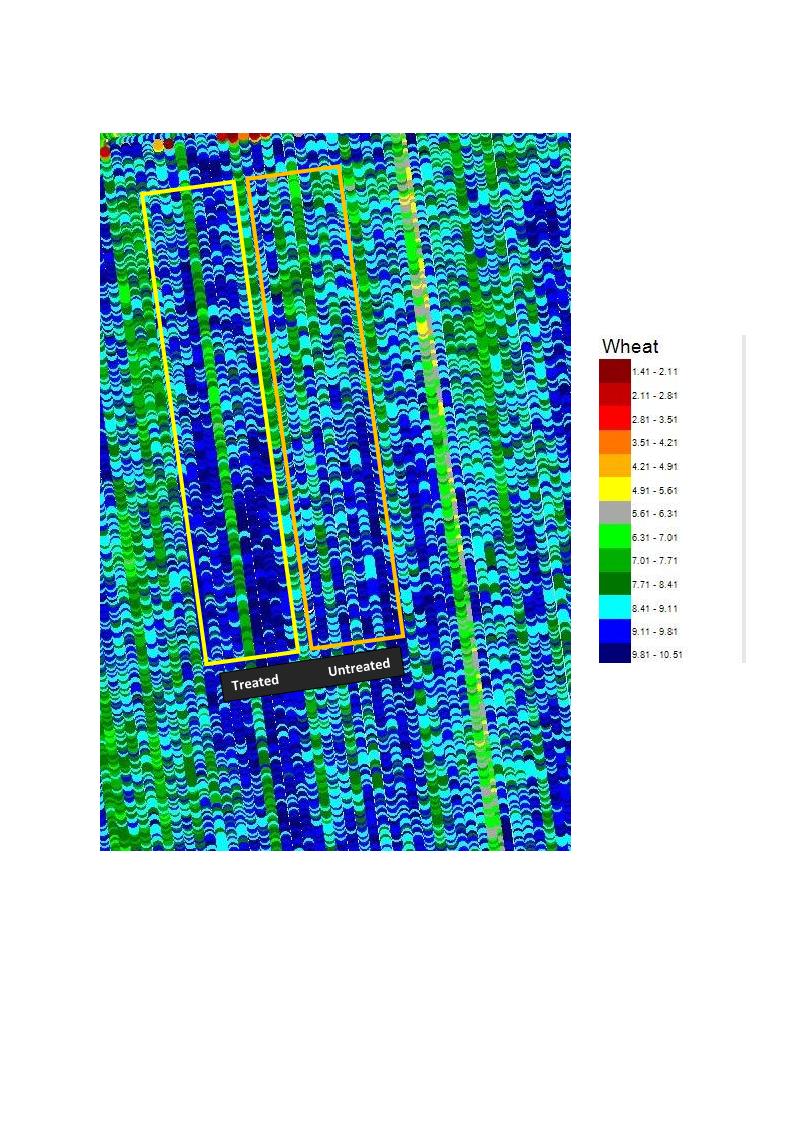

Yield map data from Kieran’s trial shows a clear difference between the tramline treated with Bridgeway (left) and the untreated tramline.

“Protein deficiency in plants has an effect on plant health, which in turn can impact both quality and yield potential. The self-production of amino acids in plants is hugely energy intensive and during periods of stress this process slows. Plants can’t store amino acids, so they begin to break down the proteins they have made to gain the amino acids they need for life. In effect, the plant cannibalises itself until they are provided,” he explains.

“Feeding a crop biostimulants offers the opportunity to increase nitrogen-use efficiency by improving its uptake through better root growth, improving nutrient import into the plant and through physiological efficiencies such as stress tolerance and improved photosynthetic capacity. But it also improves the powerhouse of the plant. If the plant has the amino acids it needs, plant health and therefore yield and quality can be optimised,” he adds.

It’s these potentials that has led agronomist Kieran Walsh to look more closely at a range of biostimulants on a more commercial scale to better understand when and where they can deliver the most benefit to his growers.

Kieran has spent a lot of time trying to understand nutrient availability on the highly calcareous and brash soils which characterize the Cotswolds. With nutrient lock-up and drought both common stressors, he was keen to discover whether Bridgeway could help support crops and still provide an economic return to his growers.

Kieran compared treatments on a number of farms and found the most marked effects were where Bridgeway was applied to Skyfall on Cotswold Brash. Three applications were applied in the spring, using 2.5 l/ha at T1 and T2, followed by 2.0 l/ha at T3.

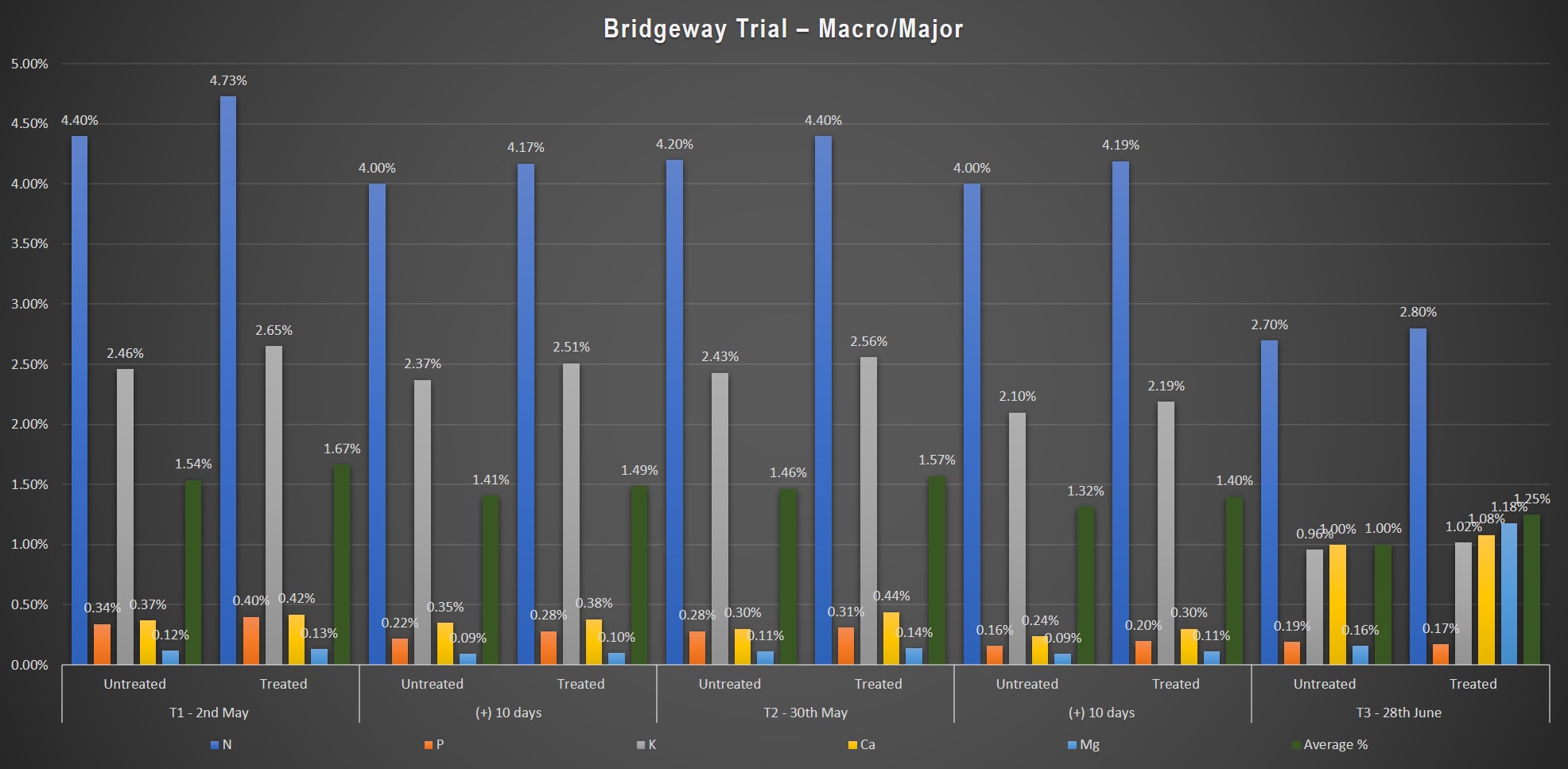

Leaf tissue samples were collected throughout the growing period to look at the effect of Bridgeway on nutrient uptake and the uptake of most macro and micro nutrients was consistently higher in the treated areas, despite the drought and heat stress this summer.

Kieran also looked at plant sugar levels using a portable digital Brix refractometer. During the course of the assessments, he found crops treated with Bridgeway all had increased sugars (23-39%) in their leaves at every assessment throughout May and June.

“Increased sugar levels indicate a healthy plant that’s photosynthesising well, producing the carbohydrates in the leaves and stems which will ultimately be crucial components of yield,” he explains.

In spite of the difficult season, the treated crop produced a 12.8% protein milling sample (11.7% in untreated) and an increased, more consistent yield (assessed by combine yield meter). But it’s the grain analysis from treated crops that really begins to paint the picture, highlights Kieran, with increases in all the elements tested with the exception of copper.

“It makes sense that a seed with its own supply of nutrients will establish and get away quickly. So if you were keeping Bridgeway-treated grain back for seed, I’d question the need to apply any seed treatments where the seed is already in good health. Money can be better spent on ensuring the nutritional health of the crop.”

Having done the sums, Kieran reckons that there was a margin over costs (MOC) of £30-35/ha from applying Bridgeway to this particular crop of Skyfall. The other crops where he put Bridgeway through its paces also showed the same trends in sugars and nutrient uptake but on average the yield increase was slightly lower, which Kieran puts down to better water availability from their chalk soils.

Next spring, he plans to use weather forecast modelling technology to time any biostimulant applications in advance of stress conditions. He’s also keen to better understand the optimum rate to apply under different conditions, highlighting that there’s still more work to be done.

“There’s definitely something happening where Bridgeway is applied. For me it’s a case of pinpointing exactly the right place, time and amount to apply. These commercial trials in combination with Interagro’s stress testing will all help us refine programmes to give growers the best value for money,” he comments.

Kieran also intends to investigate Bridgeway in organic cereal crops where he’ll be able to observe its effects on crop health in the absence of fungicide effects. “Anything can happen in crop protection at the moment, with uncertainty surrounding some product renewals and increasing fungicide resistance, so we need to be able to make best use of the tools available to us,” he adds.

Frontier have also carried out six tramline trials this season and the results are still being processed. Paul reports anecdotal differences between Bridgeway treated and untreated tramlines but says there were no huge leaps in yield where it was applied.

“Agronomists have reported several positive outcomes from the field, with one crop of OSR yielding 0.25t/ha more where Bridgeway was applied. There’s also a strong indication that there’s a synergy where Bridgeway and micro-nutrients are co-applied. If it’s used in combination with regular tissue testing, there’s an opportunity to further refine application timings and maximise the benefits of Bridgeway,” he adds.

Hutchinsons agronomist Sally Morris set out to determine the benefits of Bridgeway using a tramline trial within a commercial crop of feed wheat Relay, near Melton Mowbray. The 24m tramlines ranged from 534-570m in length from edge of headland to edge of headland, measured using GPS in the tractor. Bridgeway was applied at T1 (1.0 l/ha), T2 (2.0 l/ha) and T3 (1.0 l/ha) on tramline one, at T1 (1/0 l/ha) and T3 (1.0 l/ha) on tramline two and tramline three received a single application at T3 (1.0 l/ha). Tramline four was assessed as an untreated control.

“It was a particularly difficult season on this heavy land site, clay with a low stone content. At T1 the crop was stressed due to waterlogging after the wet in early spring and at T3 the opposite was true, with the crop suffering from drought stress,” she explains.

“The tramline with the three treatments yielded significantly higher than the untreated tramline, with a 2.208 t/ha uplift in yield. All of the Bridgeway treated tramlines yielded higher than the rest of the field average.”

Sally describes the results as encouraging and she also intends to refine her application timings next year to try and apply Bridgeway before the crop is under stress to provide a buffer. “This season I believe we may have got the Bridgeway on at the right time without realising. The T2 application went on just before some very hot days and prolonged dry conditions,” she notes.

“There’s still lots to learn but growers are interested in anything that can help protect yield and Bridgeway seems to be consistently making a difference.”

Investing in the crop

Keith Challen, farms director for Belvoir Farming Company, has 1130ha of cropping on predominantly heavy clays. Crops include winter wheat, winter OSR, spring barley, spring wheat, winter beans and spring beans. The farm is also renowned for its organic elders which go into the farms Belvoir drinks business.

Keith has used seaweed products in the past but found them to be inconsistent. He was first introduced to amino acid biostimulants on a trip to the USA and after researching them on his return, he decided to trial Bridgeway on the farm.

As a result, he made the decision to adopt its use across his acreage in 2018. Keith believes biostimulants offer an insurance policy to help protect the genetic yield potential of crops. For him, it’s a natural progression to make use of a technology which helps protect yield while providing a healthy MOC of £40/ha in his trials.

“There’s no silver bullet to do this – we need to use all the tools we have available to protect yield. Stress is certain, it’s something crops have to deal with all of the time to varying degrees – even crop protection products will stress crops – so anything that helps alleviate stress will end up in yield,” he reasons.

“I see using Bridgeway or Zonda (Bridgeway + adjuvant) as an investment in the crop. If you can improve plant health, then crops are better able to take up fungicides and fertilisers. Healthy crops are more able to fight diseases and they can also photosynthesise better so you get better value for money from inputs.”

Bridgeway has an important role to play on the farm when it comes to crop nutrition, explains Keith. “Having spent many years of paying close attention to soil health and balancing soil indices, we’ve found that our crops are showing nutrient deficiencies when we tissue test, indicating many of the elements which are plentiful in the soil aren’t readily available to plants on our soils which are very high in K, Mg and Ca,” he explains.

In 2018, Keith applied Zonda to his wheat at T0 and T1 timings. He noticed that where crops had received Zonda they didn’t show any tipping after the second dose of liquid nitrogen was applied.

“We’re always careful not to apply liquid N after a windy period when leaves may have rubbed together and dewaxed. This year we got tipping in fields that hadn’t received Zonda so it makes me wonder whether the Zonda helped crops retain wax on their leaves where it was applied,” he muses.

Some untreated strips were left in variety Graham to quantify the benefit of applying Zonda. There was a 0.97t/ha yield benefit from using 2.0 l/ha at T0 and T1, which at a wheat price of £165/t gives a value of £160/ha, less the cost of the Zonda.

The 100% plant origin of Bridgeway is also of particular importance to Keith and Soil Association approval means he can apply it to the farm’s organic elders.

“We’ve applied Bridgeway at dormancy break in the spring and again as flower heads are produced. Because the elderflower crop isn’t uniform, the effects are difficult to quantify but I’ve noticed the elder trees look greener and healthier with bigger flowers,” he concludes.

Not all amino acids are the same

When it comes to amino acid biostimulants, the source of the amino acids is an important factor to consider, advises Stuart. “Bridgeway is a plant-derived amino acid biostimulant of the highest quality, produced to food grade, which contains all 18 L-amino acids required by plants. It also contains organic N, providing a ready-to-use source of N for protein synthesis, which reduces the plant’s reliance on fertilisers.”

Amino acid origin fundamentally effects how a biostimulant can work to improve plant health, he believes. “Feeding a crop Bridgeway guarantees the supply of amino acids for building proteins and provides the most critical amino acids in higher concentration that animal-sourced amino acids. For example, Bridgeway contains 39% higher levels of glutamic acid than animal-sourced amino acids, which has multiple functions. It stimulates plant development, increases resistance to weather stress, is a precursor of other amino acids and helps adsorption of inorganic N.”

Bridgeway also contains 33% higher levels of lysine than animal-derived amino acids, which is fundamental in stimulating photosynthesis, he adds.

Pushing performance

At the heart of good crop production lies careful use of chemistry to protect the plant and maintain performance, right through the season. But optimising the efficacy of plant protection products can be challenging, while increasingly restrictive regulations limit just how far you can go.

This series of articles explores the science behind the use of adjuvant and biostimulant tools to help power both chemistry and crop performance, as well as increase understanding of why they’re needed and what they do. We’re setting out to empower growers and drive crops to reach their full potential.

CPM would like to thank Interagro for kindly sponsoring this article, and for providing privileged access to staff and material used to help put the article together.