For a large farming business in Scotland, a firm focus on efficiency is ensuring the best use of new technology. CPM finds out how on-farm trials are feeding into this approach.

When they bring out something new, you know it’ll be worth looking at.

By Tom Allen-Stevens

Tucked into the north-east corner of Scotland, near Turriff in Aberdeenshire, in a micro-climate that favours winter cereals, Sandy Norrie admits he’s been “seriously lucky” this year.

“We got winter cereals established here when others in Scotland couldn’t, and while the land varies in its fertility, it’s very common that we achieve wheat yields in excess of the magical 10t/ha,” he says. It’s not necessarily the yield he’s after, however, and by all accounts, luck has little to do with how Sandy, as arable manager of AJ Duncan Farms, achieves the results.

With 2430ha of cereals and oilseeds, the business aims to deliver sustainable, efficient food production from field to fork. At its heart lies an egg-production enterprise with 600,000 laying birds, making the farm one of Scotland’s leading producers. All of the wheat and feed barley, making up the majority of the arable crops, is channelled towards the enterprise, and intense scrutiny of costs and practices ensures cereal production delivers an efficient feed source for the birds.

Always on the look-out for new technical developments that’ll improve on this aim, Sandy joined BASF’s Real Results and trialled Revstar XE, the company’s new fungicide, on wheat last year. There are plans to trial it on winter and spring barley in 2020, and for Sandy, it’s the balance of cereals, as well as how they’re grown, that can have a marked effect on the efficiency of the egg production.

“I look closely at the market and the gross margin of the cereals – we grow barley, wheat and now also oats – but it’s the layers’ diet that dictates which performs best. Winter barley doesn’t currently deliver the highest margin, but we can include a maximum of 40% in the diet of the laying hens. What we’re really looking for, though, is high starch, low protein wheat.”

So the business has gradually scaled back its winter barley area since it started the egg production enterprise in 2011. There are 730ha of winter wheat, with KWS Kerrin, Hardwicke and now Skyscraper taking over from KWS Barrel. Winter barley still takes the highest area of cereals, with hybrid six-row varieties increasingly favoured for their “ever-improving specific weights and high yields”.

As the egg production has grown, so too has the amount of chicken litter returned to the soils, to close the loop and reduce the farm’s dependency on applied fertiliser. “We now produce enough muck for everything to get on average 5t/ha, apart from the malting barley. It means, that our relatively light soils have an organic matter on the high side, averaging 6.7%. Year on year, applied P&K has reduced from around 250kg/ha of 0:26:26 applied ten years ago to less than 150kg/ha applied today, saving approximately £75,000 per year.”

There’s a total of 23 farms across the business, all but one within a 15-mile radius and all block-cropped. This helps with the efficiency of the arable enterprise, says Sandy. “Timeliness is crucial and logistics can have a massive financial impact – just switching to liquid fertiliser saved us £18,000/year in unloading bagged fertiliser alone.”

It’s a point picked up by Andrew Gilchrist of Scottish Agronomy. The company has looked after Duncan Farms’ crops for the past 25 years, and Andrew shares the crop-walking with a colleague. “They have good kit and good staff, but what makes the difference is the attention to timeliness – they don’t hang about, and in terms of planning, they’re always ahead of the game. It makes the business one of the most efficient I’ve come across,” he comments.

Sandy’s taken part in various on-farm trials with Scottish Agronomy. “These work well alongside our replicated trial work to test some of the key findings on a field scale. We get good support from our members, keen to try out different approaches, although you must be prepared to follow through to get the benefits from carrying out a trial,” notes Andrew.

A good example is some work Scottish Agronomy has carried out on light leaf spot in OSR. “We’ve been getting very poor response from fungicides, especially those used in autumn. But they’ve almost become routine. Ten farms took part in on-farm trials, which confirmed findings from our small-plot work,” he reports.

“Sandy was one of the farmers who took part – as an early adopter of new technology he’s also not afraid to take a risk on a new practice.”

Not putting on a fungicide until the first sign of flowering took some convincing, Sandy admits, but he confirms the trials have shown no benefit from earlier sprays. The potential savings and efficiencies are clear, he says, although going forward, his focus is on application practice.

“My philosophy is that timing is just as important as the actual chemistry you apply. We have two self-propelled sprayers that operate pretty much full time at this time of year. The key to bringing further efficiencies to the business will come from ensuring they are applying the correct dose of the best product at the right time,” concludes Sandy.

The Real Results from Revystar’s greening

For Sandy, there’s a very good reason why taking part in Real Results makes perfect sense. “If you look at the products we apply to our crops, a fair proportion are made by BASF. So when they bring out something new, you know it’ll be worth looking at.”

Adexar (fluxapyroxad+ epoxiconazole) has become his mainstay fungicide on wheat, he adds. “I always like to keep ahead of the game and it’s been a while since there’s been new chemistry on the market. We’d heard quite a bit about Revysol, so it’s been good to have the opportunity to try some.”

Scott Milne, agronomy manager for BASF in Scotland, notes this is something that resonates with a fair number of growers north of the border. “Growers here tend to grasp innovation quicker than those in England. Yield potential can be higher as there’s a longer daylength during grain fill, but growers face different disease challenges. So we’ve had a lot of interest from farmers keen to know how the new chemistry performs under local conditions.”

He was particularly keen for Sandy to become involved in Real Results. “It’s a business that’s open to innovation, there’s a focus on the fertility of the soil and maximising yield potential. We knew an on-farm trial with Sandy would give a true picture of how Revystar XE would perform, and the Agronomics approach with Real Results makes it more scientific,” he adds.

In line with all 50 Real Results farmers, Sandy chose a reasonably uniform field for the trial on a first wheat of Skyscraper following OSR. Revystar was used at both the T1 and T2 timings. “We’ve used Ascra, Adexar and Elatus in the past on our wheats, and the difference between Ascra and Adexar is like splitting hairs, which is why we chose it as the farm comparison at T2. Elatus now lags behind, so we used that as the T1 comparison,” he explains.

“The BASF programme was applied to one tramline about 800m long in one of our larger fields, so although relatively uniform, there was some variation from one end to the other.”

This was picked up through the NDVI (normalised difference vegetation index) scans which were assessed by ADAS through the season. Since the difference was similar across the tramlines, this wouldn’t affect the fairness of the treatment comparison, however, notes ADAS’ Susie Roques.

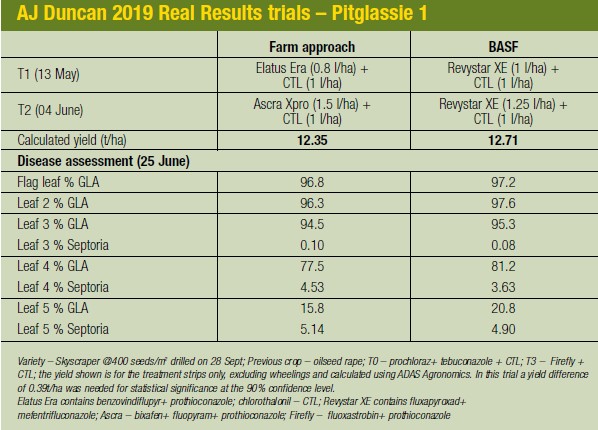

The only disease observed in the trial was septoria, at very low levels up to leaf three, she reports. “Despite the low disease levels, green leaf area (GLA) was significantly higher in the BASF treatment than the farm standard on the top three leaf layers, and septoria severity on leaf four was significantly lower in the BASF treatment.”

Sandy couldn’t see any difference from the T1 application, and it wasn’t until the T3 spray timing approached that the Revystar tramline started to stand out. “The crop held onto its GLA for longer – it wasn’t thicker but it was greener, and the crop may have been slightly taller with bolder ears,” he recalls.

A slightly higher yield was confirmed at harvest. The Agronomics approach takes yield data from the combine and uses spatial modelling and statistics to allow comparisons to be assessed with scientific rigour. At 0.36t/ha, the yield advantage falls just shy of one that Susie would class as statistically significant. “The probability of the BASF treatment yielding higher than the farm standard treatment was 0.93, where 1 indicates a certain advantage and 0.5 indicates no evidence of a difference either way,” she explains.

But it’s enough to convince Sandy, who’s planning to apply Revystar to his wheats this year. “It’s useful to have the scientific rigour, but you don’t need it to see the difference. If it repeats what it did last year in the trial, it’ll cost me around £22/ha more but deliver £60/ha more wheat, so it’s a no-brainer.”

Scott notes that Sandy’s trial pitched a typical field rate of Revystar against a full label dose of both Elatus and Ascra. “For growers who have used Adexar, Revystar is the next step up. It’s worth at least trying on a field or two, and for those growers who want to stay ahead of the game, it’s the right thing to do,” he says.

The Real Results Circle

BASF’s Real Results Circle farmer-led trials are now in their third year. The initiative is focused on working with 50 farmers to conduct field-scale trials on their own farms using their own kit and management systems. The trials are all assessed using ADAS’ Agronomics tool which delivers statistical confidence to tramline, or field-wide treatment comparisons – an important part of Real Results.

In this series we follow the journey, thinking and results from farmers involved in the programme. The features also look at some in-depth related topics, such as SDHI performance and data capture and use.

We want farmers to share their knowledge and conduct on-farm trials. By coming together to face challenges as one, we can find out what really works and shape the future of UK agriculture.

To keep in touch with the progress of these growers and the trials, go to www.basfrealresults.co.uk

Scottish trials prove persuasive

Trials carried out by Scottish Agronomy last year have confirmed Revystar delivers superior performance on septoria in wheat. The focus now is on barley, and with CTL dropping out of use on 20 May this year, that’s going to leave a hole in growers’ ramularia control, believes Andrew Gilchrist.

“We’ve carried out trials over two seasons with Revystar on winter wheat. It was difficult to draw conclusions in 2018 because disease pressure was nil. But 2019 results were pretty persuasive,” he says.

Source: Scottish Agronomy, 2019; cv KWS Barrel; yield LSD = 0.364; yield CV = 3.51; GLA LSD = 14.77; GLA CV = 27.59.

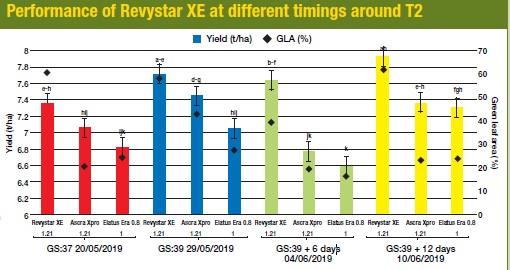

The company carried out wave trials, where a single dose of the product is applied at the T2 timing (GS39), slightly before (GS37) and then at seven and 12-day intervals after the ideal timing (see chart). “This trial gives you a good idea of both the protectant and eradicant properties of Revystar,” he explains.

“It was superior to everything trialled against it – Revystar is definitely the best septoria product we have at the moment. That’s just as well, because we’re seeing a big decline in SDHI performance against the disease in Scotland. We’re also seeing a greening effect from Revystar. That’s not as strong as we saw when the strobilurin fungicides came in, but it is noticeable and clear cut.”

But Andrew believes the debate is around Revystar’s use in barley. “Although rhynchosporium is the more damaging disease, a bigger challenge is to keep ramularia at bay without CTL.”

The problem with the disease is that it’s evolved resistance to every fungicide active ingredient used in barley apart from multisite chemistry. Believed to be stress-related, keeping the barley crop healthy through the season should help, but even that’s disputed, he notes. Experience from New Zealand, however, where growers have been unable to use CTL for some time, has shown good results from using Revystar.

“Trials I’ve seen in Ireland also show this, but we haven’t yet seen enough evidence in our own trials,” continues Andrew. “This year, we’re testing everything we can lay our hands on against the disease. Revystar is probably best used at the T2 timing in both spring and winter barley due to its ability to help retain GLA, which should help against ramularia.”

The use of Revystar in barley is now going to be the focus for Real Results trials in the north of England and Scotland, reveals Scott. “We have growers trialling it in both winter and spring barley. As with the wheat trials, this will be pitched against the farm standard approach.”

Sandy will be using Revystar on Valerie winter barley and in his Laureate spring crop. “Valerie is more prone to disease than the hybrids, while Laureate is well liked in Scotland because it’s exceptionally high yielding” notes Scott.

“CTL is currently applied at every timing because the damp weather does accelerate disease. Its withdrawal will create issues, but growers should have a go with Revystar as it’s best placed to address ramularia. In the interests of protecting the chemistry, though, a sensible approach would be to partner the best SDHI and azole on the market with pyraclostrobin – the best strob,” he concludes.