With the first new azole in around 15 years launched this month, CPM visited one of the farmers who’s been comparing it with his standard farm approach to build a picture on how it’s best used.

We’ve started to look at all things around the crop, rather than just the crop itself.

By Tom Allen-Stevens

It feels good to stand in Julian Thirsk’s wheat crop, not just because it looks to be flourishing in the mid-November sun. The fact he has a wheat crop at all is an achievement in itself in one of the toughest autumns growers have faced in recent years.

Julian’s concerns are not for the establishment challenges he’s tackled, though, but for the disease quagmire he’s yet to face. As well as running the family farm – Flaxley Lodge near Selby, N Yorks – Julian is an agronomist for NIAB TAG, looking after around 7500ha in S Yorks to Northumberland. He gets first-hand access to small-plot trials information, and for many years has carried out his own on-farm trials.

“We’ve seen both prothioconazole and epoxiconazole break down over the years. SDHIs offer considerably less efficacy than they did when they were first introduced, and now we’re losing chlorothalonil (CTL), that’s been protecting the chemistry we have,” he says. “That puts a lot of pressure on the new chemistry coming through, and if we rely too heavily on that, it won’t be effective for long.”

Towards the end of a fairly quiet year disease-wise this summer, Julian noticed unusually high levels of late disease coming in, causing wheat crops to senesce early. “Septoria is matching yellow rust in its complexity, and I believe we’re seeing strains creep in we haven’t had to deal with before.”

This year’s wheat crop may be thriving, but the concern is for the disease quagmire it’s yet to face.

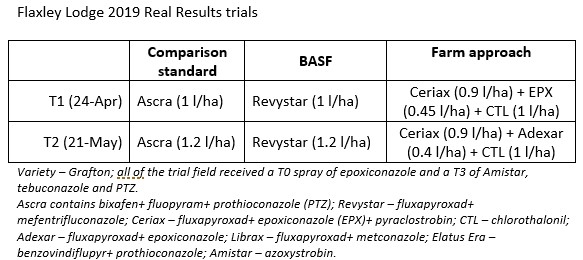

It’s to get a head start on how this pans out that Julian’s been taking part in BASF’s Real Results trials. For the past three years, he and 49 other growers have been pitching their farm standard fungicide programme against BASF’s Xemium approach, based on Adexar and Librax. This year, however, there’s been a change – the Ad/Lib approach has been replaced with Revystar, BASF’s new fungicide that will be available in the New Year and which combines Xemium and Revysol.

“The interesting aspect about the trial is there was no CTL included – purposefully, to see how the new chemistry performed in the absence of multisites,” he explains. “The variety was Grafton, which is dirty and old and the ultimate test, really. Going forward, I think variety choice has to be the first line of defence against disease. But there’s not a lot of choice in the early slot for northern growers, with many of the newer varieties suffering from weak straw.”

In another change from the usual Real Results approach, this year Julian pitched three approaches against each other. “My farm standard is based on Ceriax as I’m a strong believer that strobilurins still make a contribution to yield and extend green leaf area,” he says.

This is based on a long history of on-farm trials Julian’s carried out at the 320ha farm. The land is split between heavier silty soils, created from natural warping centuries ago by the River Ouse, and lighter land. Potatoes and sugar beet are included in the rotation on the lighter soils, along with oilseed rape and peas, which also provide the break crops between wheat and barley grown across the rest of the farm.

“We’ve always done tramline trials to test a new crop or product development,” he says. “I’m lucky in that David Tuer, our farm foreman, takes an interest in them, which is essential as it’s quite a commitment to ensure they’re done correctly.

“We started them when hybrid barleys came in. We were growing Colossus, but back then, all the fungicide recommendations were based on two-row conventional barleys. Hybrid six-rows are a completely different crop, and we soon discovered they respond differently to fungicides.”

This was where Julian learnt the value he was getting from strobilurins, which he still uses routinely across both wheat and hybrid barley crops. “We’ve looked at strob/CTL mixes at the T2 spray timing on hybrid barley, and more recently have focused on SDHIs. The conclusion we’ve come to is that the crop does benefit from two SDHIs – six-rows tend to have good disease resistance, but brown rust can come in at the end.”

This is where he sees strobs still playing a role in particular. “They give us something on both the wheat and barley and it’s not just disease protection – we consistently see a yield benefit, and I wonder whether that’s down to better end of season N utilisation. But this is the value of testing different chemistry through on-farm trials – at the end of the day, it’s all about understanding the chemistry to achieve the best value from it in terms of yields and output.”

This has also been his approach with Real Results. “When it started it was purely about the chemistry. For the first two years, it was the Ad/Lib approach that performed better than the farm standard, so we’re using Ceriax now as the standard fungicide at both T1 and T2 as this also contains pyraclostrobin.

“But the involvement with YEN (Yield Enhancement Network) now brings in much more than just chemistry. It relates the results to soil analysis and more recently to grain and leaf tissue analysis. So we’ve started to look at all things around the crop, rather than just the crop itself,” notes Julian.

He feels this more holistic approach will be essential when it comes to managing the introduction of new chemistry. “Revystar represents a big step-up in efficacy, and with CTL also dropping out of the picture, resistance will build in no time. We must look at how plant breeding can help, but also how we can nurture the crop so it’s under less stress and builds its own resilience.”

The results of this year’s trials have not yet been returned – all 50 growers receive a report that compares their approaches using ADAS’s Agronomics approach. This uses spatial modelling and statistics to allow yield-map data from the combine to be assessed with scientific rigour.

Results this year have been held back until the launch of Revystar in mid-Dec, and Julian’s reserving judgement on the new chemistry until then. “To the naked eye, there was little difference in terms of disease between the treatments. But I’ve learnt with on-farm trials that, provided you do them correctly, you should never draw conclusions until you have the real results.”

What is Revystar?

Revystar is the new cereal fungicide from BASF that combines the intrinsic and proven activity of its Xemium SDHI chemistry with Revysol, the first new azole fungicide to come to market in around 15 years.

Revysol is the first isopropanol-azole, a chemistry discovered and developed by BASF combining good performance with a favourable regulatory profile and selectivity. The molecule is claimed to be unique in that it’s the only one within the triazole group where the triazole ‘head’ sits on the ‘neck’ of a flexible isopropanol unit. This constellation allows the molecule to assume different conformations, resembling a ‘hook’.

Its flexible hook means Revysol binds to the target enzyme up to 100 times more powerfully than conventional triazoles, says BASF. What’s more, where target site mutations have developed, the molecule folds its hook conformation, allowing it to bind tightly to the same target site, which results in the death of the fungal pathogen.

After application, Revysol is rapidly taken up by the leaf, according to tests undertaken by BASF. This gives the molecule good and immediate curative effect against a number of significant fungal diseases, says the company. After uptake, the active ingredient is translocated up to the leaf tip, ensuring protection for those parts of the plant that were not reached during application.

Revysol builds inner-leaf reservoirs, says BASF, leading to a long-lasting protection from environmental influences. This complements the activity of Xemium, which leads to a broad range of activity in Revystar against key pathogens in cereals.

Revystar is also characterised by good mobility, says BASF, with Xemium showing a similar quick uptake and translocation through the leaf. The fungicide offers long-lasting protection due to what BASF terms its “double-depot” function: Revysol is well protected inside the leaf thanks to the inner-leaf reservoirs, while Xemium forms on-leaf depots, which release the active ingredient gradually.

Cautious optimism for new chemistry

A marked difference in the level of disease on the flag leaf is what Alex Borthwick, agronomist at Hoehill Farm near Market Rasen, Lincs, noticed across the farm’s Real Results plots. “In our trial, we only used Revystar at the T2 spray timing, but there was some heavy rain around 10 days later and disease started to develop, especially in the upper canopy,” he recalls.

“The difference on the flag leaves between the Revystar and the farm standard approach was really quite staggering.”

The comparison treatment, on calcareous silty clay loam, was 0.8 l/ha Elatus Era at T1, followed at the T2 timing with 1.0 l/ha Ascra. Revystar was applied at T2 at 1.25 l/ha in the BASF plot, following a T1 treatment of 1 l/ha of Adexar.

“With no CTL across the treatments, you could tell the difference compared with the surrounding crop that had received it. This really showed up on the NDVI maps supplied as part of the monitoring of the trials. But there was still less septoria in the Revystar plot.”

Alex reckons the biggest threat to disease control going forward will be the loss of CTL, but is wary of relying on new chemistry to fill the gap. “Revystar has valuable eradicant activity at T2, but we have one last year with CTL – once it’s gone, we can’t expose the new chemistry to too much septoria pressure because we’ll simply build resistance,” he says.

“So I see it fitting better at a T1 timing, giving good eradicant and some kick back potentially, once CTL has gone, which will keep the plant healthier and lower the disease pressure going into the T2 timing.”

With 350ha of winter wheat originally planned this year, that’s been revised to 240ha. But only 20% had been drilled by the beginning of Dec, to KWS Siskin and Extase, which both have good ratings for Septoria tritici.

“I’d like to try Revystar on some KWS Kerrin we’re hoping to drill, mainly in the second wheat slot, as it’s a tougher variety to keep clean. But looking ahead we’ve got to focus on varietal resistance to reduce septoria pressure, and look after the chemistry,” notes Alex.

The Real Results Circle

BASF’s Real Results Circle farmer-led trials are now in their third year. The initiative is focused on working with 50 farmers to conduct field-scale trials on their own farms using their own kit and management systems. The trials are all assessed using ADAS’ Agronomics tool which delivers statistical confidence to tramline, or field-wide treatment comparisons – a unique part of Real Results.

In this series we follow the journey, thinking and results from farmers involved in the programme. The features also look at some in-depth related topics, such as SDHI performance and data capture and use.

We want farmers to share their knowledge and conduct on-farm trials. By coming together to face challenges as one, we can find out what really works and shape the future of UK agriculture.

To keep in touch with the progress of these growers and the trials, go to www.basfrealresults.co.uk