Starting a new farming business in Northumberland comes with its challenges, but taking trusted advice, guided by sound on-farm trials and a commitment to the long term are reaping rewards. CPM finds out.

If we can replicate that 13t/ha yield across the farm that would be fantastic.

By Tom Allen-Stevens

The opportunity to take on a new farm and turn it into a success is one most progressive growers would relish. It’s one that’s come to Richard Cockcroft and his brother Stephen at Bowsden Hall Farm just outside Berwick-upon-Tweed, Northumberland.

While Stephen looks after the livestock side of the business – 50 Shorthorn suckler cows and 35 store cattle along with 1400 ewes – Richard manages the 680ha of arable. “Dad is a partner in the business but remains on the family farm in Yorkshire,” Richard explains. “We’re lucky that he’s allowed us to make the management decisions ourselves, while always being on the end of the phone for advice.”

The clay loam soils are capable of high yields, but there’s a narrow window to get the workload done.

It’s trusted advice along with on-farm R&D that are helping Richard manage the risks associated with the unfamiliar land the family purchased in 2015. The average wheat yield is around 9t/ha, but his involvement in the Yield Enhancement Network (YEN) and on-farm trials are showing the potential of his clay loam soils is far greater. For the past five years, he’s been one of the 50 BASF Real Results farmers carrying out tramline trials with the latest fungicide chemistry and putting the results through a fair degree of scientific scrutiny to ensure a result that’s ‘real’ (see panel on pxx).

“While the Real Results trial is on some of the better soil, maximising the yield on the poorer land is the bigger challenge, which last season’s weather proved,” says Richard. “We had some later drilled second wheat yield just 5t/ha as a result of the wet weather having a big effect on crop establishment. So the yield range was vast last season.”

To discuss progress, Richard’s joined on a web call by Suzanne Horn, agronomist with Alnwick Farming Consultants, and local agronomy manager for BASF, Neil Thomson. “The biggest challenge we’ve had to face since moving up here is the geographical change,” explains Richard. “With earlier drilling and later harvests, there’s a smaller window to get the workload done.”

Winter cropping – wheat, oilseed rape and oats – dominates the arable area, while the farm is a member of the local vining pea group and there’s a small area of spring barley. While the dry springs have been an additional issue to manage in recent years, these are offset to a certain extent by sea frets – heavy dews that come in as a result of the farm’s proximity to the coast.

These have their own challenges, though, as Suzanne explains. “With the past few seasons of dry springs, we haven’t been faced with a testing septoria year, and with our proximity to the coast and fast cycling of yellow rust, this disease has been more prevalent.

“Tebuconazole offers cost-effective control at the early T0 fungicide timing, bringing in the use of strobilurins and SDHI protectant products at later timings. Septoria is still our main focus for disease programs in wheat, although you can rely more on disease ratings than you can with yellow rust.

There’s a fair spread of varieties across the 360ha of wheat – Gleam, KWS Extase, KWS Parkin, RGT Saki, LG Spotlight and LG Skyscraper are in the ground. “We’ve dropped KWS Barrel, which yielded very well, but its low septoria score makes it too high risk,” says Richard. “Likewise soft Group 4 Monroe yields well in this region and weighs like lead, but broke down to yellow rust. Meanwhile Parkin has come in new for its early drilling and early harvest.”

Neil notes that having varieties with better disease scores helps with managing the risk, but should be put in perspective with drilling date. “It’s not uncommon in this area to harvest a variety close to its birthday. So when you’re drilling early and harvesting late, you can probably shave a point or two off its disease scores when you’re deciding how to manage it.

“In the spring you have to take care not to go too early with the T0 fungicide spray, which can be tempting where yellow rust is a threat. The danger is that the T1 then goes on too early, which extends the gap between the T1 and T2 applications. Only the newer chemistry is effective if you get into a curative situation on septoria.”

The climate and soils of Northumberland are not quite up to the productivity level Richard found on the Innovation Tour of New Zealand farms arranged by BASF in 2018. He was one of 15 lucky Real Results farmers who ‘scanned the can’ and were taken on the two-week tour round some of the highest-yielding cereal farms in the world. “It was really interesting to see how farms had adapted following the removal of subsidy 30 years ago,” he notes.

“But what struck me on world wheat winner Mike Solari’s farm is that he achieves these yields with relatively low seed rates and plant counts, and he’s not afraid to apply a T4 fungicide spray to extend the grain-fill period.”

Richard doesn’t have to look too far to find record-breaking wheat crops, however, with the title reclaimed from New Zealand in 2015 by local grower Rod Smith. Just next door lies a farm under the management of McGregor Farms, who work closely with BASF, and like Bowsden Hall Farm, one that’s been part of YEN for several years.

Neil’s been comparing results through the reports and the 37 different criteria on which the results are bench-marked. “The similarities between the two crops are remarkable –Gleam and Jackal, drilled and harvested at almost exactly the same time on very similar soils,” he notes.

“McGregor Farms ranked seventh in the 168 YEN entries, with a yield of 14.5t/ha, with a yield potential ranking 19th, while Bowsden Hall came 15th with 13.3t/ha and a yield potential ranking 31st. Richard’s crop had 629 ears/m² with 37 grains/ear, while the higher-yielding crop put out 404 ears/m² with 70 grains/ear.”

Richard confirms he’s reviewing seed rates, which are variably applied according to maps prepared by SOYL. “If we can replicate that 13t/ha yield across more of the farm that would be fantastic. I think the biggest contributor, though, was early drilling – we got in before the rains came.”

Hand-in-hand with early drilling comes the risk of lodging, and this could have been exacerbated by Richard’s N policy. “The Real Results field was given a four-way nitrogen split three weeks apart starting first half of March to front load the applications and utilise any rainfall for the crop. It was a calculation that paid off with the April/May dry periods which are becoming a regular weather pattern most seasons now.”

Although it turned dry, Suzanne recommended sticking with a full PGR programme, and it was a policy that worked, she notes. “We started with Moddus (trinexapac-ethyl) and chlormequat at T0, and switched to Canopy (prohexadione-calcium+ mepiquat chloride) with chlormequat at T1, with Cerone (2-chloroethylphosphonic acid) applied at flag leaf. It was an exceptionally thick crop but it stood and maintained its potential.”

Feeding into this has been the farm’s soil-improvement programme. “We’ve introduced bed-and-breakfast pigs alongside the livestock and three-year leys on some of the poorer land. These measures help to build life into the soils with additional chicken muck we buy in,” Richard explains.

“Our YEN report shows a soil organic matter level of 5.7% which I’m pleased with – we don’t yet have a good history of metrics across the whole farm, but I feel we’re heading in the right direction. It’s a long-term process with the aim of moving more towards achieving soils we can direct drill.

“We also invest in drainage every year, trying to get the fundamentals right, while using various precision farming techniques allow us to enhance yield and maximise profit margin,” he adds.

The on-farm trials and Real Results are showing Richard where the potential lies, although he accepts not every part of the farm can perform to the level these achieve. “With Suzanne’s advice, we tailor our management and spend depending on what yield potential we expect and can adapt throughout the season depending on what the weather may throw at us,” he notes.

“We have various Countryside Stewardship schemes across the farm providing wildlife habitats for farmland birds and environmental benefits on the more unproductive parts of the farm. Depending what becomes available through the ELM Scheme, this may be an option for other less productive areas.

“The long-term goals are to improve our soils through management to do more reduced tillage and increase organic matter. We want to continue integrating the livestock side of the business, that complements the arable side and should allow reduced use of artificial fertilisers. This will reduce our risk exposure as the UK moves away from subsidies and ensure a more productive, resilient future,” Richard concludes.

A Real Result expected for high potential crops

Richard’s been involved with the Real Results Circle since it started, and for him, it’s not just about tweaking the system to achieve every last bit of yield from his wheat crop. “What I enjoy is the discussion with other growers,” he says. “You also get early access to new products and can see how they fit into the farm.”

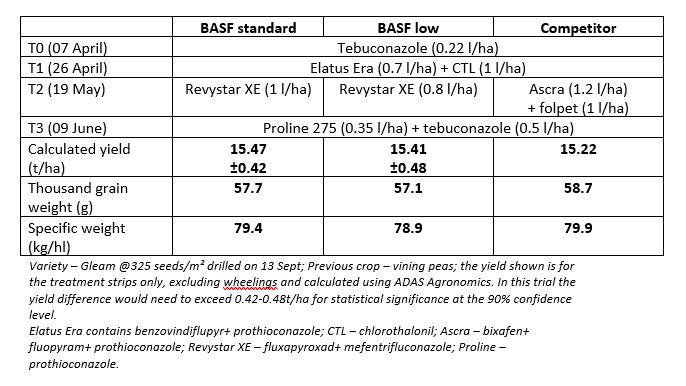

For the past two years, Revystar XE has featured as the T2 application compared against the farm standard in the tramline trials (see table on pxx). “Ascra is the current farm standard on crops with high potential,” notes Suzanne.

“On the high-yielding crops, it’s not worth risking anything other than a leading fungicide, so it’s been useful to see how Revystar compares. In neither year have we really seen a disease pressure that would show a significant response, despite having crops that started the spring with excellent potential. In a more tricky season, I’d expect the greater curative activity from the newer azole to really make its mark.”

The trial in 2020 pitched a standard and a low rate of Revystar applied at T2 against the farm standard treatment. NDVI images were taken through the season while xarvio Powerzone brings in data over 15 years to show areas of greatest potential. While these picked out in-field variations, they ran across the tramlines, according to an analysis carried out by ADAS, so should not bias the treatment comparison. However, there were no visible differences in NDVI between the treatments.

Yield data taken from the combine were analysed using ADAS’ Agronomics tool, which delivers statistical confidence to tramline or field-wide treatment comparisons. The effect of this was to show a yield increase of 0.25t/ha for the Revystar standard rate over the competitor programme and 0.19t/ha where the Revystar rate was reduced. The differences were not statistically different, however, and could have been caused by soil variation, for example.

“You wouldn’t expect to see much difference before flag leaf, but the weather broke as soon as the T2 spray was applied and we received 240mm in June, July and August,” recalls Neil. “I think that’s where the extra longevity protection has paid off with Revystar – I inspected the crop on 23 July and the area treated with Revystar was green from top to bottom and it was exceptionally thick.”

Richard agrees that green leaf area retention is where the high potential crops will benefit from Revystar. “From what I saw in New Zealand, the difference in ramularia control in barley, for example, was incredible. In our trial in 2019 you could see the difference in the Revystar-treated strip. I think its use will really pay in a high disease-pressure year.”

A field of Parkin will get the Real Results scrutiny this year, variably drilled on 13 Sept at the slightly lower average rate of 300 seeds/m². “It’s too early to decide specific treatments that’ll be applied, but this crop has potential, so I’m willing to invest to protect that,” says Richard.

Bowsden Hall Farm 2020 Real Results trials – School field

The Real Results Circle

BASF’s Real Results Circle farmer-led trials are now in their fifth year. The initiative is focused on working with 50 farmers to conduct field-scale trials on their own farms using their own kit and management systems. The trials are all assessed using ADAS’ Agronomics tool which delivers statistical confidence to tramline, or field-wide treatment comparisons – an important part of Real Results.