Does the higher yield potential of modern spring barley varieties mean nitrogen inputs can be better tailored to yields? CPM finds out more.

There’s a lack of data for spring barley grown on heavier land.

By Rob Jones

Spring barley varieties are higher-yielding and increasingly being grown on heavier soil types. A combination which means their nutrition is being reassessed to make sure they can achieve their full potential.

According to Dr Sarah Kendall, crop physiologist at ADAS Gleadthorpe in Notts, the crop’s growing popularity is putting new demands on advisors and growers, particularly where fertiliser requirements are concerned.

“Spring barley is a complex crop which has traditionally been grown on lighter soils by farmers who specialise in producing malting barley and are adept at meeting the specifications that maltsters require.

“As more farms are turning to spring cropping to help them spread their workload and combat grassweed issues, a proportion of growers are new to spring barley. There’s a need for good, modern advice on a range of management issues – including nitrogen rates, application timing and sulphur to help them meet quality specifications.”

‘Updating N & S fertiliser recommendations for spring barley’ is a three-year project led by ADAS and SRUC, and it’s funded by a number of partners throughout the supply chain, she explains.

“We have trial sites in Norfolk, Notts, North Yorks and Scotland to provide a good spread of traditional and non-traditional spring barley growing areas. We’ll be testing several varieties to assess the optimum rates of nitrogen, varietal impact and the effect of different timings on grain yield and nitrogen. We’re also looking at five different rates of sulphur to assess the optimum level.”

According to CF Fertilisers arable agronomist Allison Grundy, reviewing RB209 highlights the lack of recent evidence about the optimum timing and application rates for nitrogen or sulphur applications on spring barley.

“This knowledge gap was particularly evident in a couple of key areas,” she suggests. “There’s a lack of nitrogen management data for spring barley grown on heavier land and for application rates to reliably achieve higher grain N contents from the new, high-yielding spring barley varieties.

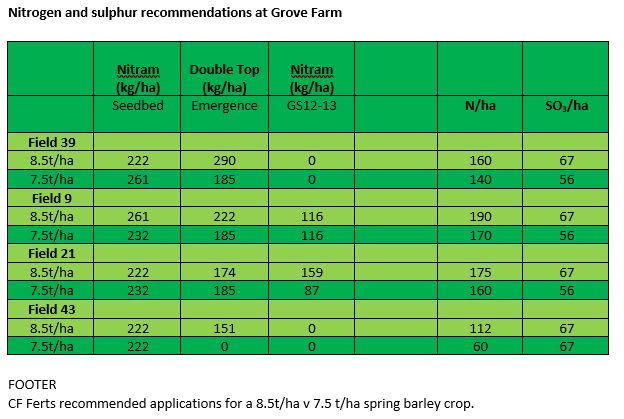

“CF Fertilisers commissioned ADAS to review, update and improve the data for use in the CF N-Calc programme, which now includes N recommendations, so crops meet high, medium and low levels of grain N.

“This can then be used in conjunction with the CF N-Min service, the only nitrogen test to measure both Soil Mineral Nitrogen (SMN) and Additionally Available Nitrogen (AAN), enabling the total nitrogen available to crops during the growing season to be more accurately quantified.

“The work is part of an ongoing progress to better understand the process of growing spring barley generally and on heavier soils.

“It’s also important to ensure our N-Calc recommendations continue to meet farmers’ yield/quality aspirations, account for changes in economic circumstances, minimise the environmental impact of crop production and reward our customers’ investment in our products.”

Identifying where nitrogen can be used most effectively in spring barley and tailoring its application to optimise crop production is a vital part of their approach at C.W. Richardson and Sons 400ha at Grove Farm, near Sleaford, Lincs.

With more spring barley now in the rotation, Chris Richardson is keen to participate in the project as he believes it’ll help him maximise the performance of his spring barley whilst helping him meet end-market contract requirements.

Fine-tuning N applications last year enabled him to achieve spring barley yields of 7t/ha despite the incredibly dry season, which was not much less than the farm’s five-year average, and he did this while making a £12/ha saving in fertiliser costs.

Having grown spring barley for a specific high-N market for three years, Chris was keen to find out if more nitrogen could be applied to this relatively new crop without penalty.

“Spring barley has traditionally been a minor crop in this area and, prior to 2015, the last time we’d grown it was 1982, but now it is a very important part of our rotation,” he explains.

“During the past four years we’ve increased spring crops from 10% of the farm to 45%-50% to help combat grassweeds, particularly blackgrass.

“It’s an increasing issue in this area and present in a couple of our own fields, so we want to prevent it from becoming a major problem. Chemicals are becoming less effective and increasingly costly, which has reduced significantly the difference in margin between winter and spring crops.

“All of the original fields that were spring cropped three years ago have now been returned to winter cropping, proving the effectiveness of this approach.”

With salad rape grown one year in six, spring barley is one of only three break crop options and along with oats and beans provides the opportunity to achieve multiple chits of weeds and volunteers which are sprayed off with glyphosate before drilling.

In 2018, Chris grew 90ha of Explorer spring barley on contract to Glencore Agriculture, some for seed and the remainder on a buyback contract for Anheuser Busch, the brewer of Budweiser beer, who offer an enhanced premium for 1.8%-1.9% N barley.

Budweiser is brewed using water, barley, malt, rice, yeast and hops, and Chris has been told the high N barley is required to counteract the low N content of the rice.

“The heavy land at Grove Farm is well suited to producing spring barley with a higher grain N and the £35/t premium more than compensates for Explorer’s slightly lower yield compared with other varieties,” he says.

Chris has also been a committed user of the CF N-Min system for the past ten years. “The N-Min recommendations have always been spot-on and crop yields have been equal to, or better than those we would have achieved by using our previous fertiliser rates,” he explains.

“That reduces our costs, avoids wasting a valuable input and eliminates any potential environmental impact from over-application. It also gives us the confidence to tailor our applications precisely to soil and crop requirements.”

Spring 2018, when the spring barley trials began, marked the start of a particularly challenging season in terms of weather conditions.

At the beginning of the year Chris planned to drill the four trials fields in late March, but heavy rain meant that it was the third week of April before the crop went in the ground and even then, the land was still ‘plenty wet enough’.

The application of 60-90kgN/ha in the seedbed encouraged the crop to emerge rapidly and with the onset of warmer weather it shot through the growth stages. However, no significant rain fell during throughout the remainder of the season, which adversely affected the crop’s potential and how it was managed.

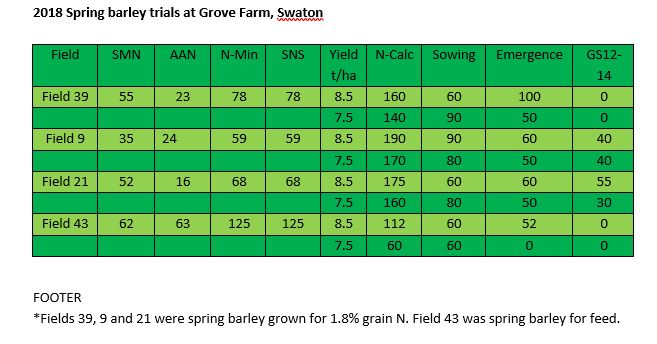

Chris uses the CF Fertilisers’ EnCompass programme through Arthur Baldwin, area manager for fertiliser distributor ACT. The initial recommendations were calculated following the N-Min tests and were based on the farm’s 8.5t/ha five-year average for spring barley grown in a trial situation, where yields are based on the measured area between tramlines and therefore slightly higher than the overall field average.

However, as the crop had been drilled three weeks late and the forecast was for continued dry weather throughout the shortened growing period, Chris and Arthur reasoned it would have a lower yield potential and reduced the target yield to 7.5t/ha.

Fertiliser applications were based on that figure and as the season progressed it became evident that was a good call. In what would prove an extremely challenging season the saviour for the spring barley was that it had got off to a flying start and its roots had penetrated the heavy land quickly where they were able to tap into what little moisture was available.

Following the N-Min N-Calc recommendations Chris applied the second dose of nitrogen as Nitram (34.5%N) during the first week of May and a third during the third week of May.

Nitrogen applications would have been in a range from 160-190kgN/ha but using the revised 7.5t/ha figure brought it down to 140-170kgN/ha, a 20kgN/ha reduction which saved £12/ha.

However, on one field (Field 43) with very fertile soil the SNS was substantially higher at 125, compared with readings of 59, 68 and 78 for the other three. Chris and Arthur followed N-Calc’s recommendation for a total of just 60kgN/ha, all of which was applied in the seedbed in the form of DoubleTop, saving £37/ha.

“Field 43 tends to be quite dry,” Chris points out. “I had a small amount of Nitram left in the spreader after the third application on the other fields and decided to apply 40kgN/ha outside of the trial area to see if it had any effect.

“The fact that it didn’t came as no real surprise because soil moisture not nitrogen was the limiting factor. The N-Calc recommendation had been spot-on. Had I used the higher rate across the whole field, the margin would have been reduced by £14/ha because the crop wasn’t able to take it up.

No rain fell in late May, June or July and the dry conditions made a huge difference to how the crop developed, explains Chris. “It was much shorter than in previous years and disease pressure was much lower, so we spent less on fungicides and PGRs, making it cheap to grow.”

But the lack of soil moisture meant that the third nitrogen application on three of the four fields wasn’t fully utilised. The four fields were harvested in mid-Aug, a week and a half earlier than normal, he points out.

“It was amazing that despite the incredibly dry season the average yield for spring barley was 7t/ha, only slightly below the revised level on which fertiliser recommendations has been based and not much less than the farm’s five-year average.”

Knowing your soil nitrogen reserves is helpful to correctly tailor nitrogen applications to crop requirements, Allison comments.

“While previous CF trials highlighted the importance of measuring spring seasonal Soil Nitrogen Supply (SNS), especially when growing for a lower grain N market, the new guidelines reflect the fact that there is no one-size-fits-all recommendation.

“The results from the first year’s trials must be treated with a certain amount of caution because of the exceptional weather, but they show clearly the benefits of tailoring nitrogen applications to crop conditions and potential.

“The work that started at Grove Farm in 2018 will continue in spring 2019 and because it’s unlikely that all of the nitrogen applied last season was recovered by the crop we can assume that, subject to lower over-winter rainfall than last season, levels of soil N are likely to be moderate to high, all will be revealed by N-Min tests this spring.

According to Sarah, it’s hoped the ongoing project will help growers optimise their spring barley nitrogen applications.

“Modern spring barley malting varieties offer the potential for high yields to be achieved, and the trials done in the project will help growers understand how to optimise management of nitrogen and sulphur to maximise yield and hit the quality specification required,” she says.