Slugs left unchecked can have a devastating impact on crops, affecting both yield and quality. With current pesticide control options under ever increasing environmental scrutiny, growers must continue to demonstrate best practice as well as follow current IPM protocols. This Tech Talk focuses on product choices and how pellet quality affects slug control.

Slug pellets are almost unique in broad acre agriculture in that the pest isn’t targeted, it has to seek them out. CPM asks how to devise an effective control strategy.

IPM requires thinking about the pest before it becomes a problem in the crop.

By Lucy de la Pasture

Integrated pest management (IPM) practices to contend with slugs begin as soon as the current crop is cleared. Depending on risk, slug pellets may well need to be applied to reduce crop damage during its most vulnerable growth stages, but pellet choice can influence the effectiveness of applications.

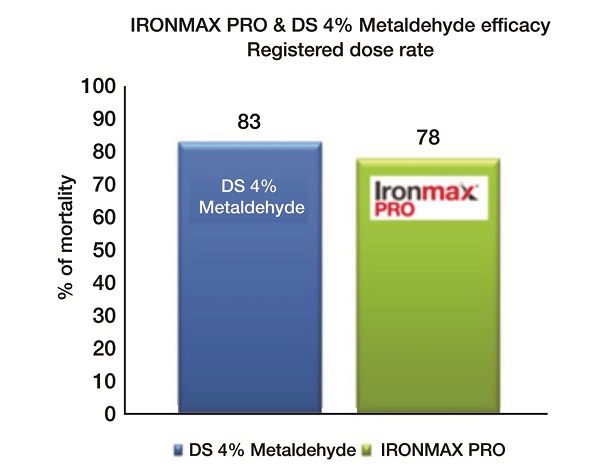

Metaldehyde remains the market leading molluscicide but there’s been a definite swing towards ferric phosphate over the past few seasons. Although both actives are equally good at killing slugs, they work in very different ways.

De Sangosse manufacture both active ingredients and UK commercial manager, Simon McMunn explains the differences between the two and how pellet quality can influence slug control.

OSR seedlings are particularly vulnerable to slug attack until they reach the four true leaf stage.

What is the current position with metaldehyde?

After a decade of stewardship, metaldehyde has reached a critical point as it’s currently being considered for reauthorisation by the regulatory authorities. A decision is hoped for within the next few months but it’s impossible to pre-empt the outcome of the process. At best growers should expect to see significant label changes governing the use of products containing the active.

How does this affect slug control?

Because of the possible restrictions on the use of metaldehyde, it’s likely there will be a greater move to ferric phosphate, first approved in the UK in 2009. Although ferric phosphate has been shown to equal metaldehyde in terms of its efficacy, there are a number of important differences between the two active ingredients in the way that they work.

Because ferric phosphate has a different mode of action (MoA) to metaldehyde, this leads to a visual difference in the field because dead slugs aren’t visible on the soil surface. This requires a change of mindset when assessing the crop after pellet application because the only visual sign that it’s working is that the damage to the crop ceases.

How do they work?

Both active ingredients prevent damage to crops by quickly stopping the slug from feeding on crops by interfering with the slug’s metabolic processes, ultimately causing their death.

Metaldehyde works by destroying the structure and organelles of the mucus-producing cells in skin, footsole and digestive tract of the slug, resulting in the excessive slime production seen when slugs have ingested metaldehyde pellets.

Ferric phosphate has a completely different MoA. When a slug eats a proportion of a ferric phosphate pellet, iron displaces calcium in the gut, paralysing the system which stops the slug from feeding on the crop.

In practice when a field has been treated with metaldehyde, dead slugs and slime trails are clearly visible. In contrast, where ferric phosphate is applied the slugs becomes more sensitive to light, so they move underground and this is where they eventually die, hidden from sight.

What trials work has been done?

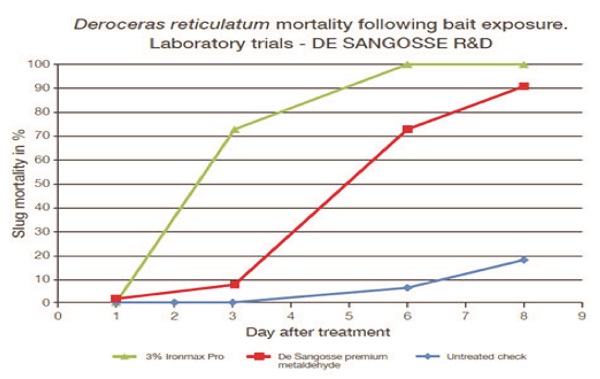

According to the results of extensive trials, ferric phosphate and metaldehyde are of comparable efficacy where an equal quality bait is used, for example if both products are durum wheat pellets manufactured using a wet process.

Although both active ingredients stop slugs from feeding, formulation of the pellets also has an effect. IronMax Pro (ferric phosphate) achieves faster slug mortality because of additional attractants used in its formulation. De Sangosse have screened over 100 substances to find the ones which are most appealing to slugs and have incorporated two of these in the IronMax Pro formulation.

How important is pellet quality?

Pellet quality is the key to effective slug control and there are four factors that must be perfectly balanced to maximise the efficacy of pellets. To achieve this isn’t an easy task and wet process durum wheat is the formulation that enables all four quality criteria to be best met.

Even ballistics are important for pellet spreadability. If the pellet size, consistency and density isn’t consistent then the result is an uneven spread pattern, which will give inconsistent control. Larger pellets are heavier so can be reliably spread to a further distance than smaller, lighter pellets.

Attractiveness is an essential element for any slug pellet. Molluscicides are one of very few pesticides where the pest has to preferentiality seek the bait out, inducing the slug to leave its crop food source and consume the bait.

Palatability is another must for slug pellets, with those made from a pasta base proving to be the most appetising to slugs. These wet process durum wheat pellets have the best durability, enabling them to endure moisture and remain palatable. In the field this increase in weatherability can be critical during wet periods when slug activity is at its peak.

Persistence is the final attribute that defines a quality pellet. They need to be able to withstand rainfall events and remain viable, while retaining their palatability for a 2-3-week period in the field to help protect the crop during vulnerable growth stages.

What size pellet is best?

According to research by De Sangosse, a slightly bigger pellet is the optimum way of achieving all four quality criteria and give the highest levels of slug control. The company has found a pellet 2.7mm in length delivers excellent metrics compared with the standard-size of pellet, which is around 2.4mm.

Increasing the size of the pellet slightly means there is a consequent reduction in the number of baiting points. Even so, at recommended rates the slightly larger pellets will still deliver more than 30 baiting points/m2, widely considered by experts to be the optimum number for slug control. Slugs have the ability to travel 2-7m per night in the search for food and it’s only when baiting points fall below the optimum that control may be compromised.

How do you get the best control?

To achieve best control, slug pellets must always be used as part of an overall integrated pest management (IPM) strategy. The aim is to protect crops as they move through their most vulnerable growth stages, from emergence to four true leaves.

IPM requires thinking about the pest before it becomes a problem in the crop and putting measures in place to reduce the risk, often before the crop is even planted. As well as weather conditions, the rotation also has a big effect on slug pressure, with oilseed rape, cover crops and brassica margins all increasing risk.

Soil and stubble management are the start of cultural controls for the next crop. Where ploughing is practiced this has a useful effect disrupting the slugs’ habitat by burying trash and inflicting mechanical damage. But secondary cultivations are as important, with care needed to avoid the cobbly seedbeds which allow slugs to thrive.

Where min till is preferred, moving the surface trash around helps by disturbing the slugs’ egg lying habitat and exposing slug eggs to UV light. Conserving the natural predator population can favour increased predation of slugs and their eggs by natural enemies, such as Carabid beetles.

The biggest weapon in the cultural armoury is a set of rolls, which can be usefully employed to consolidate seedbeds so that slug movement, shelter and hiding places are reduced.

Trapping is an essential measure to assess the need for pellet application when threshold levels are breached and can be set up in stubbles, with pellet application made pre-drilling if populations justify it.

What about metaldehyde?

Where metaldehyde is used, it’s important to follow the enhanced stewardship guidelines issued last year by the Metaldehyde Stewardship Group. These include the additional requirement that no pellets should be allowed to fall within a minimum of 10m of any field boundary or watercourse. Ferric phosphate has no buffer zone requirements so can be applied to the field edge where headlands need protection.

Quality slug pellet gives greater persistency

Andrew Robinson of Heathcote Farms in Toddington, Beds runs an 1150ha cereal enterprise, growing wheat, oilseed rape, beans and barley grown on soils ranging from Hanslope Series heavy clays to greensand over clay.

“The rotation on the clay is wheat, OSR, wheat, OSR, wheat, beans, and on the lighter soils it’s wheat, barley, OSR. The heavy clay soils with OSR in the rotation provides a perfect environment for slugs to thrive. We do get slugs on the lighter land but not so many.

“We focus on our soil quality which has steadily improved by using compost and sewage sludge and by employing minimum tillage techniques. This has helped reduce the amount of slug pellets we use on the farm without compromising yield or quality. Last year we didn’t have many slugs, so the OSR only had one treatment. Wheat after beans received no slug pellets and after OSR we only applied pellets to about 35% of the crop,” says Andrew.

Deciding which product to use is a joint decision between the two experienced operators and the management. Last year 10 bags of three different products were applied over fallow ground to compare spreadability, pellet quality and control.

“We tried two De Sangosse premium products and ferric phosphate. All three were similar in spread pattern up to 32m, but when it came to product quality there was only one contender.

“What stands out most about the De Sangosse pellets is that when they get wet, they don’t fall to pieces which makes them much more versatile and ensures greater persistency. They provided at least three weeks activity in the wet but can go for as long as five weeks. This also has clear environmental stewardship benefits,” he adds.

“De Sangosse pellets produce little or no dust because of the pasta base, which means we can apply safely behind an ATV using a twin disc and hopper attached to a bogey unit. The operator wears all the appropriate protective and safety garments and sits at least 5m in front of the application point.

“We’ll apply slug pellets only when we can see 10-12 slugs per trap, even though this is well over the normal threshold. We always check the size of slug and the weather before applying pellets. After an application we will monitor slug numbers for the next few days. There is no point in applying slug pellets if there has been a deluge of rain, and we will wait for about 24 hours before going on the land.”

Environmental stewardship is a key component of farm management strategy, he says. “We try to avoid applying slug pellets near watercourses and on headlands, but when it’s necessary, there are clear advantages of only using a quality pellet.

“Where we have tested ferric phosphate, we couldn’t find any evidence of dead slugs which at the time was disconcerting, but it’s because slugs that have ingested it will move away and die under the ground. We know that it must have worked well though because on land that was treated with it the volunteer OSR grew back.”

Effective slug control: top tips

- Stubble and seedbed management – provide an opportunity to reduce slug populations before the next crop is planted.

- Make good use of the rolls – consolidate seedbeds as much as you dare to limit slug damage.

- Choose quality slug pellets – wet process durum wheat pellets give the spreadability, palatability and durability needed for good slug control.

Sponsor message

Cost-effective slug control isn’t complicated, but it does rely on pellet quality. De Sangosse recognises that palatability, persistency, attractiveness and ballistics are essential criteria to ensure maximum performance and efficacy.

Delivering all four of these characteristics is determined by using only the finest quality durum wheat flour, rather than ground wheat, and this goes through an advanced wet manufacturing process to form a high-quality pellet. The addition and extrusion of water during formulation minimises dust and makes it better able to resist varying climatic conditions. Pellet size and density is critical to enabling accurate and uniform spreading at the distances required today.

De Sangosse slug pellets are more consistent and durable and with a high level of persistency, pellet integrity is assured. The company’s range includes metaldehyde-based slug pellets as well the most effective alternative ferric phosphate-based product, IronMax Pro.