Understanding phosphites

Unium Bioscience is at the forefront of phosphite research and formulation technology. Our aim is to inform so that growers can make educated and data-backed product choices which will provide the most cost-effective results.

Understanding the many faces of phosphites could hold the key to unlocking their potential. CPM explores their role in agronomy, how they work and how the physical characteristics of phosphite salts can affect outcomes.

Phosphites are very reactive in an unstabilised form.

By Lucy de la Pasture

Phosphites are perhaps one of the best known biostimulants and have been used in agriculture for several decades. They’ve charted an interesting agronomic course, where research enthusiasm has flipflopped from nutritional products, to fungicides and finally to biostimulants – on the way creating lots of controversy still evident today

Science has discovered a lot about phosphites but the knowledge hasn’t necessarily been transferred to the field, according to Dr Nigel Grech, co-founder of Unium Bioscience and a researcher based in the Unites States.

Nigel believes phosphites are a fantastic tool if you know how, when and why to use them. CPM draws on his 30 years of research and his experience using phosphites on his own family farming operation in California.

What are phosphites?

Phosphites have existed on Earth long before there was even an oxygen rich atmosphere, forming part of the natural terrestrial and marine phosphorus cycle. They are inorganic derivatives of phosphorous acid and a reduced form of phosphate, carrying one less oxygen molecule.

The first interest in using phosphites in agriculture was as early as the 1940s and 1950s where they were investigated as a more soluble form of phosphorus than phosphates, with greater soil mobility. In the 1970s, an organic phosphorous acid derivative (a phosphonate) was discovered to have an indirect effect on a small group of fungal pathogens, primarily oomycetes such as downy mildew and Phytophthoras, so attention switched away from other uses.

The resulting registration of Aliette (fosetyl-aluminium or aluminum tris(ethyl-phosphite) as a patented fungicide caused concerns that fertiliser products could be used in disease management, which side-lined the development of fertiliser and biostimulant products until the patent expiration in the early 1990s. Science has gone on to demonstrate that phosphites are multifunctional and have a very clear biostimulant effect.

Can plants utilise phosphites?

The use of a phosphite product depends on its label but it’s true to say that phosphites are definitely a biostimulant, can be a fertiliser and can be a fungicide.

While they can deliver phosphorus to plants, phosphites can’t and shouldn’t be applied to crops at a level comparable with phosphate fertilisers. When dosed and applied correctly, phosphites commonly confer significant agronomic benefit.

Science shows that most soil microbes can metabolise phosphite to phosphate – a legacy of their primordial existence when there was no oxygen in the atmosphere. It’s also postulated that phosphite can be converted by plants into a form they can use by utilising the many bacteria contained in their rhizosphere as well as inside them.

Research is now very close to showing that these bacteria can mediate the conversion of phosphites to phosphates. Once inside a plant, phosphites are completely systemic and can be easily detected. In trials, phosphites are never permanently in plants and eventually are no longer detectable. It’s intimated that this is because they are converted to phosphate.

In soils the picture is very clear. Collaborative research with California State University is joining the dots and has shown that when soils were surveyed throughout California, 70% of the microbes in soils sampled possessed the phosphite dehydrogenase gene – indicating most soil microbes retain the ability to convert phosphite to phosphate. Although these pathways may play a relatively minor role in direct phosphorus uptake, phosphites can be used in phosphorus management strategies to improve the nutritional efficiency of plants.

How do they work?

When applied to crops, phosphites induce an upregulation of the phosphorus acquisition metabolism, effectively switching on the plant’s pathways to acquire more of the element. A relatively small amount of phosphite can achieve this (200-300 g/ha), as well as delivering a positive effect on both root architecture and reproductive growth.

Phosphite also upregulates pathways that help plants manage stress. One of the main ones affected is the shikimic acid pathway – unique to plants and microbes – which produces molecules to help alleviate abiotic and biotic stresses. This biochemistry is of such importance to plants that they allocate around 20-25% % of their photorespiratory energy to this pathway.

Is formulation important?

The cation the phosphite is bonded to is as critically important to the safety, stability and efficacy of a product as the formulation itself.

Phosphites are very strong reducing agents, meaning they strongly scavenge for oxygen. They can be very damaging to agrochemicals in formulations and tank mixtures as phosphites are very reactive in an unstabilised form.

They have very different properties to phosphates – being smaller and much more soluble. Unlike phosphates they enter the plant rapidly and, like phosphates, they are very mobile within the plant, heading to areas of growth such as the shoot tips, roots and meristems. Phosphite products typically have a high salt index and being highly soluble means there’s a risk of inducing osmotic shock and causing crop damage under certain application scenarios.

This means formulation is important, particular where phosphites are applied as seed treatments, in greenhouses, to early soft tissue growth, applied during hot weather or if there are residues on the leaf from a previous spray that may interact with the phosphite.

One of the main challenges in the formulation of phosphites is that they are highly deliquescent, which means when the solid is exposed to humid air it will liquefy. This is true of all the commonly available phosphite products based on potassium, sodium and ammonium. Although phosphites are available in many forms, the cation partner which produces the lowest salt index and highest stability is calcium, which makes calcium phosphite products much safer and more versatile to use.

What difference does stability make?

Using a stable calcium phosphite enables formulations that aren’t possible with more deliquesent phosphites, such as suspension concentrates, wettable powders, water dispersible powders/granules and granules. On a practical level this means calcium phosphite can be integrated with other agrochemicals in formulations or in a spray tank without adverse negative reactions occurring.

Unstabilised phosphites also become highly phytotoxic when mixed with some products, eg copper, and many labels carry warnings to this effect. The huge advantage from using calcium phosphite is not just that these adverse reactions don’t happen, the stabilised phosphite offers the opportunity to also reduce some fungicide rates and thereby the ecotoxic effects of some fungicides, such as copper.

Another plus for calcium as a partner is that it’s typically transported in phosphate-rich molecules in the plant, so the pairing is very synergistic as an application. Importantly, calcium phosphite can also be formulated or combined as an end use mix with biocontrol/beneficial bacteria very effectively – together providing a platform to support biology with soft chemistry.

Are phosphites cost-effective?

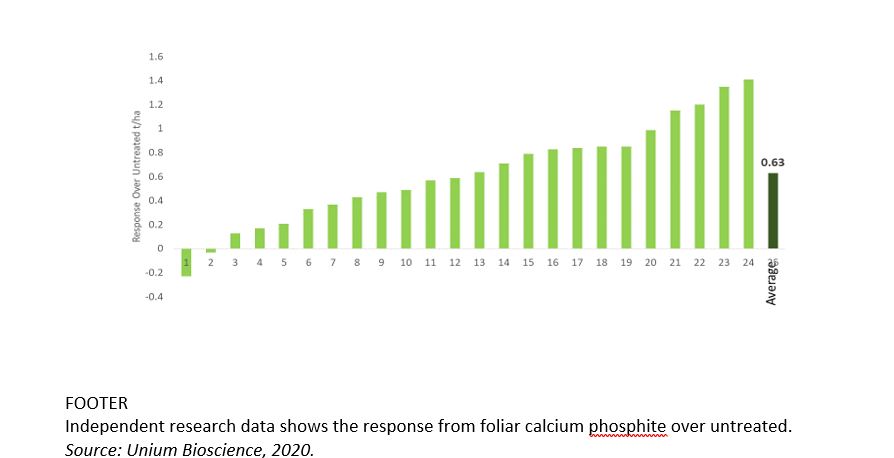

In the data from independent trials over the past three seasons (2018-2020), the average yield response to Unium’s calcium phosphite in winter wheat has been 0.63 t/ha = £120/ha ROI. This relates to a 91% chance of breakeven or above over 24 trials.

In oilseed rape the average yield response (2018-2020) is 0.3 t/ha = £105/ha ROI. This gives an 86% chance of breakeven or above over 28 trials.

Winter Wheat trials 2018-2020

When’s the best time to apply?

Because phosphites have great utility in mediating phosphorus delivery, application should be early in the growth of the crop for best effect.

They can also help mitigate abiotic stresses – so a stabilised phosphite product can be applied with post-emergence herbicides to reduce any negative effects on crops. Phosphites can also be integrated into fungicide programmes in potato and cereal crops where there may be synergistic effects as the biostimulant works to mitigate stress.

In crops with large partitioning into reproductive growth, such as cereals and strawberries, then application at later growth stages is also beneficial.

How can I maximise benefit?

To get the maximum benefit it’s important to understand when to apply phosphites, what they work best with in the tank, how they work, the correct dosage and the properties of the formulation being applied. Aim to apply at the correct growth stage of the crop to have the desired effect. Application in a tank mix is the most efficient for growers but to do this safely, a stabilised form of phosphite is required.

Trials have shown that crop species differ in their responsiveness to phosphite application. The most responsive tend not to form mycorrhizal associations so less readily assimilate phosphorus, eg oilseed rape and alliums.

In winter wheat, phosphites can be beneficial when applied with plant growth regulators because they appear to enhance their effect. This has been seen in trials with chlormequat and gibberellic acid, though the mechanism behind the effect isn’t yet understood. Using phosphites in this way offers scope to either lower the rates of PGRs or enhance their effect on crops.

Top tips – Understanding phosphites

- Not all phosphites are the same – different cation formulations have different physical properties which can affect tank-mixing and crop safety

- Use a stabilised formulation – these may cost slightly more per litre but are used at a lower rate per hectare (50% or less of the dose rate of generics)

- Understand what you are trying to achieve – this is important to get the right product, used at the right dose rate, at the right time

Product integrity pays dividends

Fourteen years ago, Richard Smith formed contracting company Danum Farming with a neighbouring farmer and the firm now looks after the combinable crops operations on both farms and two neighbouring estates, covering around 1,820ha in South Yorkshire. The land is ring-fenced, with each farm responsible for its own individual costs but farmed as a whole.

Alongside the combinable crops business, Richard has grown his own 324ha potato enterprise, producing potatoes for McCain which are destined for the fast-food chain McDonalds – a business which recognised him as their ‘outstanding grower of the year’ in 2019.

“We’ve used phosphites on arable crops for a number of years for general plant health and stress mitigation, particularly in oilseed rape crops,” he says.

But it’s the potato crops where calcium phosphite has a major role to play on his fertile Grade 2 limestone soils. The processing varieties grown can be susceptible to internal browning and hollow heart which are caused by calcium deficiency.

“Although we have calcium in our soils, it readily locks up as calcium phosphate and becomes unavailable to plants. Potato plants move calcium from their roots to the foliage, but it can’t be transported in the other direction, ie from the foliage to the tubers,” he explains.

“If the foliage runs short of calcium, often during periods of rapid haulm growth, then plants take calcium from the tubers if there’s insufficient free calcium ions available in the surrounding soil for root uptake.”

To avoid this scenario, Richard dusts calcium phosphite (formulated as a wettable powder) onto tubers at planting, which provides a source of available calcium in the soil surrounding the tuber. He has found this also brings health benefits, promoting a vibrant healthy root structure, which helps the potato plant access nutrients from the soil.

“When the haulm starts to expand rapidly, we apply 1 l/ha of calcium phosphite with the blight spray and repeat this every fortnight until we’ve applied a total of 3 l/ha. The idea is that the foliar application provides the leaves with a source of calcium during the period where it may run short, preventing the plant from pinching additional calcium from its tubers. It’s not just the calcium that’s of benefit, the phosphite brings other benefits to overall plant health,” he says.

Richard plans a further foliar application of calcium phosphite at mid to late bulking because of its positive effects on tuber wall integrity, skin set and skin health – all of which have benefits when putting potatoes into store.

The role of calcium phosphite is of such importance to his enterprise that Richard values the integrity of the product above anything else. “The biostimulants market is essentially unregulated and some products aren’t necessarily what they say they are, so I use a product that’s based on research at the University of California and is well-formulated. Basically, I know what I’m getting.”

Sponsor message

Unium directors collectively have over 55 years of experience of phosphites, being one of the lead developers into the UK market. This gives a strong background when producing formulations that are backed by peer reviewed research and research trials on many different crops.

Over the past three years Unium has developed a quality range of calcium phosphite products – Unical ST for use as a potato seed treatment and Calfite and Acalsa, both 50% suspension concentrate foliar liquids, with a water dispersible granule formulation soon to be launched. These products contain SafePhite Technology giving growers the reassurance of the highest level of performance with uncompromised crop safety and tank mixability.