In light of increased cabbage stem flea beetle damage and a significantly reduced oilseed rape area nationally, protecting yield is a key priority this year. Our uniquely formulated pod sealants provide a solution to help growers protect yield and maximise a crop’s gross margin potential.

Getting oilseed rape crops through to this point in the season has been a tortuous journey for many. CPM finds out how applying a pod sealant can reduce the chances of falling at the last hurdle and hold on to yield.

The pod sealant will form a mesh over the seam.

By Lucy de la Pasture

Oilseed rape has had a bumpy ride this season, particularly where cabbage stem flea beetle larvae have taken their toll. More than ever, every seed is precious so reducing the risk of pod shatter before and during harvest is likely to be a worthwhile strategy.

Shed seed isn’t just a loss of yield, it presents a problem in future seasons from volunteers which have been linked to high erucic acid issues in seeds going to the crush. De Sangosse was one of the first manufacturers to develop a pod sealant, so CPM talks to the firm’s Rhodri Morris about how they can help reduce losses.

What is pod shatter?

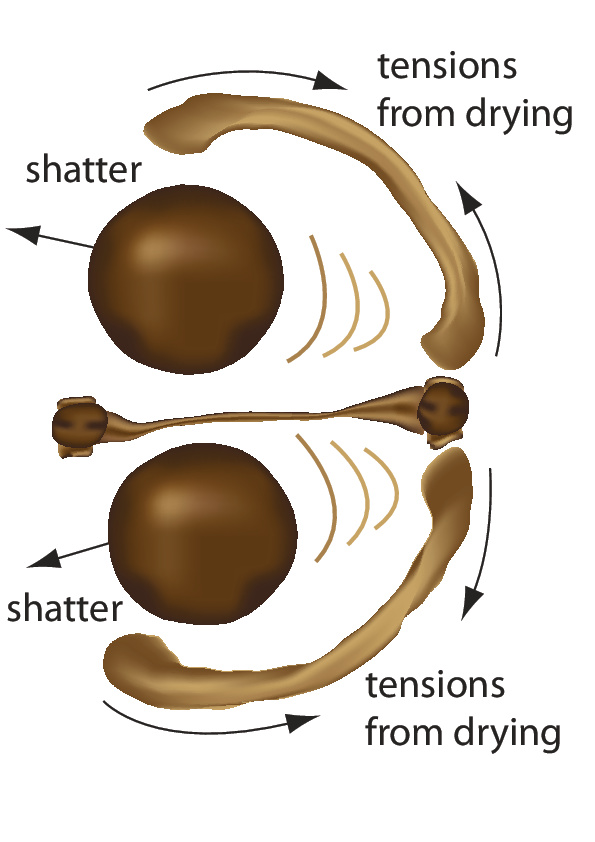

Pod shatter is the premature loss of seed from the pod, which can be caused either by mechanical damage when going through the crop with the sprayer or combine and by severe weather conditions, such as thunderstorms and hail. Not only does pod shatter result in loss of yield, there’s also an increased need for volunteer OSR management in subsequent crops.

When the crop is damaged by the sprayer, this occurs particularly in the tramlines when glyphosate is applied for harvest management – as the sprayer passes through the crop it knocks seeds out of the pods. Yields from the tramlines can be 30-35% lower than the body of the crop. Further losses at the header can also occur during harvest as pods become brittle.

Repeated wetting and drying cycles can cause OSR pods to shatter prematurely.

Pod sealants were introduced over 10 years ago as a means to prevent premature seed loss, primarily in OSR crops. Those formulated by De Sangosse use the highest quality polymer (a propriety blend of styrene-butadiene) which offers strength and flexibility as the pod matures and prepares to split.

What’s the cost?

Pod shatter triggered by extreme weather events in the run up to harvest can typically result in yield reductions of between 8-12%, but losses can be much higher as a result of hailstorms and heavy rain. The problem arises from the swelling of ripe pods in wet weather, which then contract in dry weather.

This is compounded by uneven development of the crop, which is all too common where damage from CSFB has occurred. In the OSR plant, mature pods split to release their seeds so when maturity is uneven, the more mature seed becomes increasingly prone to pod shatter compared with less mature pods further down the raceme or on branches.

Timeliness of harvest is another factor which has a direct effect on pod shatter losses. In the run up to a late harvest, brittle over-mature crops are particularly at risk of pod shatter as plants become older and drier with age. When harvest is on time, yield losses may be 2-5%, whereas when harvest is delayed by the weather, pod shatter losses can be considerably more.

What about genetic solutions?

In recent years plant breeders have made great progress by introducing pod shatter genes into hybrid OSR varieties. It’s a useful trait and provides some in-built protection against losses, but there isn’t a silver bullet to prevent pod shatter, and 60% of the national crop is still made up by conventional varieties.

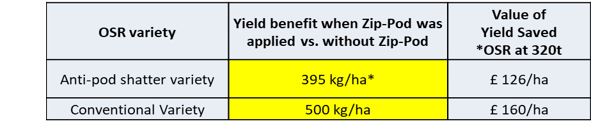

The benefit of genetic resistance to pod shatter can be enhanced by the use of a pod sealant – there’s no question that together the two mechanisms provide the best protection for the crop. The evidence is clear from trials that both are working with one another to reduce pod shatter, with an extra 0.395t/ha of yield where genetics and pod sealants are used in combination. That’s worth around £126/ha based on an OSR price of £320/t, giving a return on investment from applying a pod sealant of around twelve to one.

Zip-Pod works with shatter resistance

Average results from nine independent trials Source: De Sangosse, 2020.

How do pod sealants work?

It will depend on the quality of the pod sealant how they work, but the De Sangosse pod sealant, Zip-Pod will go through three stages.

The first of these is evaporation. De Sangosse pod sealants form a film when the latex begins to dry on the surface of the pod. As water leaves the surface, the drying process occurs by way of evaporation and the polymer particles begin to draw closer together. The time taken to achieve this depends on the evaporation rate. Once most of the water has left the emulsion, the polymer particles are left closely packed together.

The second stage to the process is deformation. This begins when the particles become densely packed within the emulsion, with only a small amount of residual water left.

The last stage is coalescence and interdiffusion. In these final stages, virtually all of the water has evaporated and it’s then that the pod sealant begins to take on its desired properties as the boundaries between polymer particles begin to disappear. Polymer chains in one particle diffuse towards the chains of an adjacent particle and begin to intermingle. This is known as coalescence, sometimes described as polymer reptation, derived from the word reptile, because the movement of long-chain polymer molecules – slithering and sliding past each other – resembles a tangled mass of snakes.

As the closely packed molecules develop interconnected bonds, they form a homogenous structure. This step is critical for mechanical performance because without it, the final film won’t have the necessary mechanical strength which pod sealants require to perform optimally.

When a pod sealant is applied, it’s not necessary to cover the whole pod. The target is the seam of the pod and, in particular, the top of the crop as this will senesce first and be more prone to damage than lower in the canopy. The pod sealant will form a mesh over the seam and the styrene-butadiene (latex) allows flexibility for natural changes in the pod, while the strength will help prevent premature splitting. Again all of these points will depend on the quality of the formulations used.

Are there trials data?

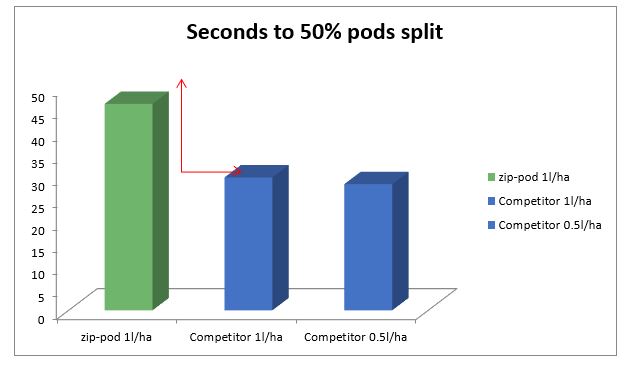

The Random Impact Testing (RIT) regime employed by John Innes Centre involves automated shaking of pods in a cylindrical container with metal ball bearings at a standard intensity. After each eight second interval, the percentage of broken pods is assessed, allowing a ‘decay’ curve to be plotted from which the time taken to break half the pods is calculated.

In these trials, Zip-Pod was compared with its closest latex competitor in the UK. There was a clear difference on the time taken to split the same number of pods, which is due to Zip-Pod’s stronger and more flexible formulation.

RIT testing at John Innes Centre

John Innes Centre

What’s best practice?

De Sangosse advocates application when the majority of the pods are green and bendy (generally around the time of the Cereals Event in June). This is earlier than the more ’convenient’ timing together with a desiccant. The reason for this is that when the crop is still green it has the flexibility to be ‘laid over’ as the sprayer passes, thereby mitigating losses from a following application because the sprayer will miss the crop.

The effects of the pod sealant will last around 12 weeks, so application at BBCH 80-82 (pods green and bendy) will endure through until harvest. A rate of 1.0 l/ha in 100-150 litres of water is considered optimal. If the earlier timing can’t be achieved, an application with glyphosate can still be made at the later pre-harvest management stage.

One very important practice after application of any pod sealant is to immediately wash down the sprayer internally. The addition of 0.1% of Activator-90 is the best way to achieve this and will help remove any residual pod sealant present within the sprayer system.

Top Tips – reducing pod shatter

- Earlier timing is optimum – apply Zip-Pod at 1.0 l/ha at GS80-82, when pods are green and bendy.

- Lower water volumes are best – aim for 100 l/ha and don’t exceed 150 l/ha.

- Don’t forget to clean out sprayer after use – use a non-ionic adjuvant at 0.1%.

Still worth protecting yields in a difficult season

To maximise the yield potential of OSR, it’s best to avoid the ‘convenience application’ of a pod sealant with a pre-harvest desiccant and instead adopt a separate earlier pass, says Hutchinson agronomist and Cambridgeshire farmer Simon Wilcox.

He still believes OSR is a crop that can return as much as first wheat, as well as being a valuable break crop in the rotation.

“There’s no mistaking that it’s is an expensive crop to grow, but with the potential of such high returns it’s worth doing the job of growing it properly,” he says. “It’s also the first crop in the bank at harvest, which gets money back in the account during the season. But if the crop hasn’t established well before mid-Oct, then burn it off and drill second wheat.

“My advice is to always apply a pod sealant, even in a bad season where yields might well be compromised. Understandably growers will want to reduce input costs in a struggling OSR crop but, in reality, this can often be a false economy. Now is the time to seal the pods to conserve remaining yield and quality potential,” he says.

“Appraise crops at senescence to assess potential based on the presence of disease and flea beetle damage,” he suggests. “Those crops that show any damage should definitely be protected with a pod sealant. Where pods look like they might be about to senesce early and lose yield, Zip-Pod will protect them against shattering.

“Applying a pod sealant is the last decision made before harvest. It’s always a good insurance policy against rain, wind and thunderstorms and a catchy weather harvest. A pod sealant also helps to reduce harvest losses at the header.

“If it rains in July, pods are at greater risk of shattering. Zip-Pod gives up to 12 weeks protection of the crop and is flexible on timing. Essentially the product should be applied once when the pods are malleable.”

Simon explains that as OSR starts to senesce, the co-polymer latex in Zip-Pod effectively holds the pods together.

“Allowing a crop to naturally senesce can return higher yields and more oil, but the disadvantage of this strategy is that harvesting can start encroaching on the wheat harvest.

“Applying a pod sealant also has a big impact on reducing volunteers, which in turn keeps erucic acid levels down. Tolerance levels have just been reduced from 5% to 2% so it’s even more important to minimise the contamination levels, bearing in mind OSR seeds can remain dormant in the soil for over 10 years.”

Sponsor message

De Sangosse has been providing research-backed solutions for over 40 years and continues to promote the use of more competitive agricultural models in order to respond to food-related concerns, climate variations, environmental challenges and crop issues.

At this time of year protecting oilseed rape yield by applying pod sealants to reduce pod shatter is now, more than ever, a key priority. Not all pod sealers perform the same, but there is a clear benefit to be seen from using them through higher yields and reduced volunteers.

When yield losses from pod shatter were once considered an unavoidable consequence of growing oilseed rape, the introduction of De Sangosse’s pod sealers has challenged conventional thinking.