Finding a solution to a problem is almost impossible when the cause hasn’t been established. CPM takes a look at the latest research into elevated erucic acid in rapeseed and how this has resulted in new advice to growers.

It’s a problem that’s probably been evolving for decades.

By Lucy de la Pasture

Albert Einstein once said, ‘If I had an hour to solve a problem, I’d spend 55 minutes thinking about the problem and five minutes thinking about solutions.’ For the OSR industry the problem has been unexpectedly high levels of erucic in seed going to the crush, but the true source of the problem remained a mystery – a situation which meant the solution was far from clear.

So AHDB commissioned NIAB to find out the answer to the million-dollar question: where are these elevated levels of erucic acid in OSR loads actually coming from?

Research shows that OSR volunteers are the main source of raised erucic acid levels in rapeseed.

Double-low varieties of oilseed have an erucic acid content which is inherently in the region of 0.1%, well below the current limit of 5%. Even though the percentage of loads coming in with high erucic acid has been low, it’s a situation that has become magnified by a proposed lowering of the legal limit for erucic acid to just 2%, posing potential problems for crushers and OSR growers alike, explains AHDB’s manager for quality and safety research, Dhan Bhandari.

“There was a lot of finger pointing going on in the supply chain but with no hard proof, it was impossible to pinpoint the most likely source of contamination. Possible causes included contamination from high-erucic acid (HEAR) seed in accidental mix-ups on farm or at merchants’ stores, incomplete cleaning of seed, and wild cruciferous seeds with a naturally high erucic acid content, such as mustard and charlock,” he comments.

“Other possibilities included cross-pollination between double-low varieties and either wild crucifers or volunteer OSR plants, and the presence of HEAR volunteers in the crop, which were widely grown before the introduction of double-lows, as well as more recently for industrial usage and renewable fuels,” says Dhan.

“The researchers at NIAB have expertise in erucic acid and have been carrying out the testing on certified OSR seed for years,” he adds.

Leading the research was oilseed and pulse specialist Simon Kightley, who explains the 2% limit for erucic acid in seed isn’t new.

“It’s been in the Federation of Oils, Seeds and Fats Association (FOSFA) contract for rapeseed for many years, in line with the 2% limit for National Listing of low erucic acid varieties when they were introduced in the 1970s,” he says.

“In the absence of sufficiently sensitive testing equipment at intake, the limit had always been applied with a degree of tolerance. More recently (2015-2017), spikes in the erucic acid content of extracted oil and the introduction of improved near-infared spectrophotometers (NIRS) created awareness of a problem that had previously gone unnoticed,” comments Simon.

The erucic acid problem remains small, with currently around 1.5% of loads being penalised or rejected in the UK, but it’s significant, says Simon.

“Even after mixing in with the general heap in communal stores, the problem was beginning to show. It only takes one fully high-erucic acid seed with a level of 50% in 50 seeds to raise the level to 1%. Two or three seeds and you’re going to be over the limit.”

And this is what Simon and his team looked at in the research. In the forensic investigation, a set of 50 samples from commercial OSR crops was taken during harvest 2017 and provided the core of the study; which looked at the different testing methodology and the presence of any high-erucic weed seeds in the samples. A further subset of 12 samples was then looked at in detail, with examination of 50 individual seeds to identify whether any cross-pollination or volunteer contamination was occurring.

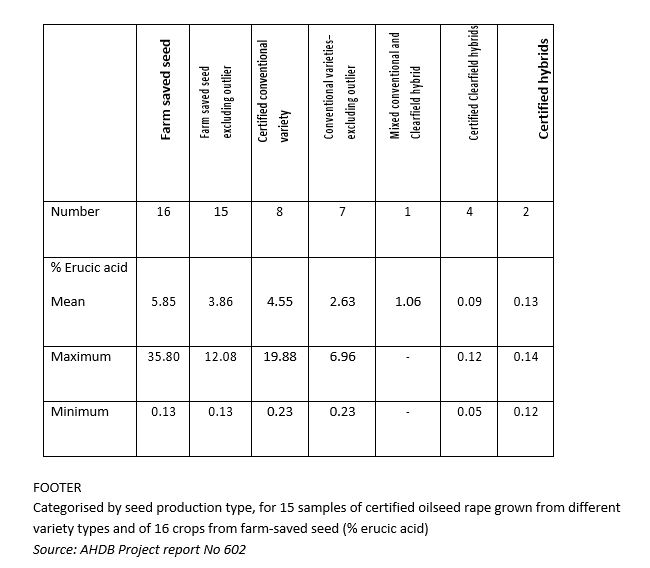

The initial analysis of samples showed a variation in erucic acid contents which highlighted farm-saved seed as being at the highest risk of testing high, with Clearfield and hybrids varieties at the other end of the spectrum, testing well within erucic acid limits.

“The results identified a small risk from erucic acid presence in sown seed, particularly farm-saved seed, and this gives rise to the advice that seed for sowing should be tested for elevated erucic acid and rejected if it’s more than 1%, although hybrid seed appears to be very clean in this respect,” explains Simon.

“As well as testing any seed intended for home-saving, it’s important to stress the importance of seeing a test result for any bought seed,” he adds.

Erucic acid content of harvested crop

But it was the study of samples looking at every single seed that started to explain what may be happening in UK crops as far as erucic acid is concerned. “The results showed that in all 12 samples, contaminant seeds with varying levels of erucic acid elevation were identified, and it was clear it was these that were responsible rather than a drift in the erucic acid content of the crop as a whole,” explains Simon.

“Most of the seed were at or below the limit of detectability of 0.1% erucic acid content. This gave a very clear indication that the low-erucic acid trait itself is very stable. The contaminated seeds came from high-erucic volunteers or from crossing between volunteers and the sown crop, possibly over repeated rotations,” he says.

These varied in proportions between the samples studied but were found at levels up to 50%. Simon says the result of the study points to the most likely cause being that crops have bred and cross-bred with volunteers from high-erucic acid OSR crops which have resurfaced, often many years after they were originally grown as a crop.

“Growers should be aware of these from their farm records and will have to learn to live with them but exercise very tight agronomy to restrict their numbers,” he suggests. “The move to very low target populations makes this harder because there’s a greater influence from any volunteers that become part of the crop.”

But looking back further in time, it’s possible to see that the volunteer problem isn’t all down to the past few rotations, it’s a problem that’s probably been evolving for decades, believes Simon.

“Before the low-erucic acid varieties were introduced, a lot of the early varieties were around 40% erucic acid. Seeds from these will have come up every time OSR has been grown in a field and, with the high-erucic trait being dominant, will have perpetuated themselves and crossed into the low-erucic crop,” he explains.

The other source of contamination was the period of industrial cropping, on set-aside, from about 1994 to 2002, points out Simon. “Quite a lot of high-erucic rape was grown as industrial contracts at that time and my feeling is that it wasn’t always recorded as such.”

One of the expected sources of high erucic acid from wild brassica weed seeds was found not to be responsible for elevated erucic acid in this research, but Simon highlights they could pose serious potential threats if uncontrolled.

“Of the few charlock seeds that we found and tested, the erucic acid came out at about 42%. Controlling brassica weeds is often difficult in mild winters, when the few available herbicides can’t be used until the crop is sufficiently waxed-up, after frost, to give it sufficient protection.

“This is where cropping with Clearfield varieties and the associated herbicides come in. The imadazlinone-based herbicides can be used from establishment onwards to take out brassica weeds and non-resistant OSR volunteers,” he says.

For growers with very high levels of erucic acid in recent crops, Clearfield varieties might now be the only way forward, he believes. But he adds a word of caution: not all brassicas are as susceptible as others.

“This year we found to our cost at one of our Norfolk sites, that runch (Raphanus raphanistrum) is far less sensitive than charlock (Sinapis arvensis) to Cleranda (imazamox+ metazachlor) and needs taking out a lot earlier, at around the 2-leaf stage.”

Progress in reducing erucic acid must continue

Even though the UK’s largest rapeseed crusher has reported an improving situation in comparison to previous years, OSR growers are being urged to continue the progress made in reducing levels of erucic acid.

High levels of erucic acid is bad news all round, believes Martin Farrow, general manager of ADM Erith. For growers it could lead to deductions or outright rejections which in turn leads to supply issues for crushers, he explains.

“While the legal limit on erucic acid in rapeseed oil products across Europe is currently set at a maximum of 5%, there are EU proposals to reduce this to 2%, which brings it in line with FOSFA contracts and the industry in general.

“Growers who have concerns about their levels will be reassured to know that ADM Erith Crush has no plans to apply claims to deliveries of rapeseed which have less than 4.99% erucic acid content. It’s encouraging that we’ve seen a reduction in the number of loads over 2% in comparison to last year,” he comments.

Although Martin’s comments provide some reassurance to OSR growers’ concerns, Owen Cligg of United Oilseeds says it’s important that the progress in reducing erucic acid levels continues and the work funded by AHDB will be really helpful for growers in understanding the problem better.

“Background levels have generally been on an upward trend over the past five years but there’s now evidence of a decline, possibly because of more awareness of the issue and growers taking action,” he says.

The research carried out by NIAB advises growers should ensure that any seed – purchased or farm-saved – has been tested and shown not to pose a risk by exceeding erucic acid levels for seed.

Owen reinforces the report’s conclusions, saying the best cultural practices to minimise volunteer OSR in crops is crucial where any background threat exists. He also advises that samples from every load transported to crushers should be retained for reference in the event of disputed test results.

He subscribes to the view that volunteer OSR cross-pollination has contributed to the issue and an increase in the planted area of Clearfield OSR has helped combat the problem. So-called ‘weed seed’ and higher erucic acid rape (HEAR) varieties grown for industrial use are also possible causes.

United Oilseeds has implemented testing of all loads destined for storage to ensure an accurate picture of erucic acid levels is understood before loads are delivered to the crush, he adds.

Risk points for high erucic acid

- Seed source – ask for a written declaration of erucic acid content for certified seed and send any home-saved seed for testing. Keep a sealed sample of any seed used in case of later dispute.

- Pre-planting – assess risk from farm cropping history (ideally 15 years). Volunteer OSR poses the greatest risk so delay any cultivations for one month after harvest so any seed buried has dormancy and spray off any emerged OSR volunteers and weeds with a non-selective herbicide.

- Established crops (weeds and volunteers) – consider wider row spacing for inter-row hoeing or use Clearfield varieties.

- Harvest – adopt strategies to minimise seed shedding from pod shatter and segregate all double-low rapeseed from any HEAR or home-saved seed. Keep representative samples from each field.

- Contracts – retaining representative samples provides the opportunity to retest in case of any disputes and to identify fields with specific problems.

Research roundup

AHDB Project No 21130055, ‘Investigation of high levels of erucic acid in consignments of double-zero oilseed rape varieties’ was carried out by NIAB in partnership with Campden BRI and ran from March 2018 to Feb 2019 at a cost of £46,000.

Guidelines to minimise the risk of erucic acid in double-low oilseed rape are available at ahdb.org.uk/erucic-acid and have been produced in association with Agricultural Industries Confederation (AIC); British Society of Plant Breeders (BSPB), National Association of Agricultural Contractors (NAAC); National Farmers Union (NFU); NIAB TAG; Official Seed Testing Station (at NIAB) and Seed Crushers and Oil Processors Association (SCOPA)