As two major AHDB-funded weed-resistance projects conclude, a third is underway. CPM reports on the research effort and how it’s gearing up growers in their quest to quell problem populations.

There are blackgrass populations we now know that are less susceptible to glyphosate.

By Tom Allen-Stevens

In September 2010, an AHDB-funded blackgrass project got underway to explore how winter cropping could be sustained with the rising threat of herbicide-resistant blackgrass (see panel on below).

At the time, random sampling carried out by Rothamsted Research and funded by CRD had identified resistance to post-emergence herbicides in as much as 50% of the blackgrass populations tested, although growers were reporting generally good levels of control from Atlantis (iodosulfuron+ mesosulfuron).

In terms of resistance management, multiple applications of glyphosate to stubbles to clean up blackgrass is very bad practice.

With resistant blackgrass now an established problem across most of the UK arable area, and a threat to the rest, the findings of that body of research are now enshrined into standard practice, points out Dr Paul Gosling of AHDB Cereals and Oilseeds. But five years on, in Sept last year, a new project started to manage the resistance risk of glyphosate. So could history be repeating itself?

“There’s been no case of resistance to glyphosate confirmed in the UK to date,” he assures. “However, so many resistance mechanisms exist, it’s likely we’ll see it becoming a problem in ryegrass or blackgrass within the next three to five years.”

Reliant on glyphosate

The worry is that growers are increasingly reliant on glyphosate as resistance to post-em herbicides has risen. “We’re hearing anecdotal reports of multiple applications of glyphosate to stubbles to clean up blackgrass. In terms of resistance management, that’s very bad practice.”

And there are signs of some localised populations of grassweeds showing tolerance, he reports. “Initial surveys have revealed a large variation in susceptibility and a number of farmers have sent in samples they believe are resistant. There are blackgrass populations we now know that are less susceptible to glyphosate, so it’s vital all growers take steps to delay the process of resistance building in the field.”

There is now powerful and convincing evidence of the overall benefits of delaying autumn sowing.

This is the main focus of the new five-year project currently underway. “It’s looking at how to use glyphosate to best control grassweeds with a minimum risk of resistance developing. The ultimate aim is to update the stewardship guidelines that were issued last year.”

This project runs alongside the BBSRC/AHDB-funded Blackgrass Resistance Initiative, he adds. “BGRI is represented on the steering group and close collaboration is maintained through joint activity.”

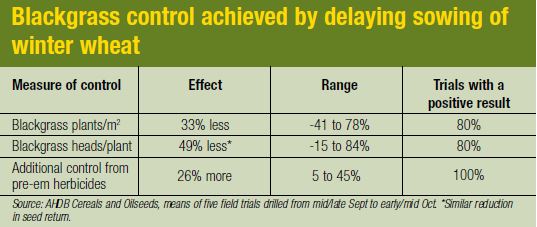

Meanwhile, the final report from the previous project that focused on control strategies to beat resistant blackgrass in a winter-cropping rotation has been published. “We now have powerful and convincing evidence of the overall benefits of delaying autumn sowing of winter wheat as part of a strategy to improve control of blackgrass by chemical means,” notes Paul Gosling.

“Growers needed the numbers, and it’s largely thanks to this research we can be confident about the control strategies that have been widely adopted in bad-blackgrass situations.”

For Richard Hull at Rothamsted Research, which led the five-year winter-cropping project in collaboration with NIAB TAG, there was a fundamental question researchers were looking to answer. “We knew that resistance to ACCase herbicides was well established and that ALS resistance was creeping up. We wanted to know if it was actually possible to achieve a sustainable level of blackgrass control in an autumn-sown crop without these herbicides.”

Three aspects were trialled. “We opted for one that would offer a big advantage – delayed drilling – and one that would make a smaller contribution, which was seed rate. We also looked at the impact of spring-sown, in comparison with autumn-sown wheat.”

The results largely backed up previous research carried out by Dr Peter Lutman and Dr Stephen Moss some 30 years earlier, so why were new trials necessary? “Blackgrass populations had changed, and so had wheat varieties. But the key difference here was the experimental design.”

The plots were larger, drilled on specific dates with set seed rates. Uniquely, each was split, with only half of it drilled so there was a true comparison for the effect of each treatment. “We could look at them independently, or study the interaction between them. Such detailed, robust scientific analysis had never been managed before on this type of trial and it means we’ve great confidence in the data generated,” notes Richard Hull.

“But the really novel bit was the interaction of the pre-em herbicide. We didn’t think we’d see a discernible difference in its efficacy through delayed drilling. But we really did, and it was remarkably consistent across all five sets of trials.”

Average control rose from 47% for a mid/late Sept drilling date to 73% for early/mid Oct. But this level of control crumpled if spray timings slipped. “We looked at the effect of applying a peri-emergence herbicide, compared with a true pre-em. For a Sept drilling date, there was a small difference. But in Oct, average control dropped from 80% to just 50%.”

Another aspect explored thoroughly in the trails was the pattern of blackgrass emergence. “We tagged plants at emergence and followed them through to see how much seed they produced,” recalls Richard Hull.

“87% of blackgrass germinates by mid Dec, and just 3% germinates in March, April and May. These late emerging plants produce on average just one head, with this being half the size of a head from an autumn-germinating plant.”

Problem eliminated

That doesn’t mean to say a blackgrass problem will be eliminated in a spring-sown crop, he cautions. “Where there’s a high burden, 3% of a lot is still a sizeable population. Also, you shouldn’t underestimate the contribution of the herbicide programme – one aspect these trials have shown in particular is that cultural methods play a useful and vital role, but to control blackgrass, you must combine these with effective herbicide use.”

But going forward, it’s the efficacy of glyphosate that’s likely to be the focus of AHDB-funded related research. The initial year of the new project has been spent gathering information on current practice and setting up the new trials, explains Lynn Tatnell of ADAS who leads the research programme.

“What’s surprised us is just how much current practice varies. Growers use completely different dose rates, and some make multiple applications to stubbles, while others rely on just one. Generally, rates are a lot lower than we were expecting or hoping, which may be a worry. Label guidance on glyphosate use in stubbles is vague, however, which may explain the divergence in practice.”

A number of grassweed populations have been identified in commercial crops that now show reduced sensitivity to glyphosate, following research carried out by Dr Laura Davies in her recently completed PhD, reports Lynn Tatnell. “We’re monitoring these carefully. They can still be controlled with a robust rate, but the fact they exist is a concern.”

The field trials are being carried out in conjunction with Agrii, Frontier and Hutchinsons, who each have established blackgrass trials sites, and this new work fits in with their programmes. “We’re focusing on the window from harvest through to drilling, looking to find out what flushes, and what’s required to control it,” she says.

Either one or two glyphosate treatments are being applied at different timings from early Sept to mid-Oct, as well as an untreated trial. “Most glyphosate treatments will be 540g/ha, although we will be assessing the difference one 1080g/ha dose makes, so there’s a total of six treatments,” she says.

All plots are cultivated at the start then half of each plot gets a second cultivation at drilling. The drilling date will be mid-late Oct, and all plots will then receive a robust pre-em and post-em herbicide programme.

“We’re intensively monitoring the blackgrass emergence between flushes, as well as what comes up in the following crop.” The sites will be contained and treated sensitively, she adds, so that if any regimes propagate resistant populations, there’ll be no danger to commercial crops.

While the field trials focus on what’s logical and practical, a set of container trials will look to push resistance to the limit. “We’ve collected some of the UK’s most resistant blackgrass populations and are treating them in a way to increase the likelihood of glyphosate resistance evolving,” reports Lynn Tatnell.

Resistance pushed

Samples that originated from Peldon in Essex, where resistance to other modes of action was first identified, for example, receive a low dose of glyphosate when the plant is well tillered – a timing not recommended in the field. “We have some survivors and have collected the seed so we can repeat the cycle and assess the effect over the course of the project.”

A final part of the work is to validate an in-field diagnostic test for resistance. Developed at Jealott’s Hill in Berks by Syngenta, the RISQ (Resistance in season quick) test uses an agar gel to test whole plants that have ‘survived’ a glyphosate treatment. “If the test proves reliable, it will give growers a quicker measure of resistance levels of a problem population without having to wait for it to go to seed,” she notes.

In the meantime, growers using glyphosate should follow the new guidelines to reduce the risk of resistance developing, she stresses. “Do what you can to prevent survivors, as repeat applications present the highest risk. Use the manufacturer’s recommended dose rate for the weed sizes present and use alternative control methods, such as cultivation. And keep a close eye on populations – test any samples that may have survived treatment.”

When it comes to broadleaf weeds, the guidelines for herbicide resistance has been updated following the conclusion of the three-year project looking at ALS resistance. These now include advice on how to take samples. “With chickweed in particular, this isn’t a straightforward job,” notes Lynn Tatnell.

“Broadleaf-weed resistance is not widespread, but it’s an acute problem where it’s found. Using a wide range of active ingredients, relying less on ALS herbicides, will help, although this will put greater reliance on pendimethalin, which is up for review.”

Paul Gosling confirms that more populations of resistant poppies and chickweed have come to light and cases of resistance in groundsel have been confirmed. “We’re not expecting a resistance explosion, but this is a creeping problem and can become an issue for those who take their eye off the ball,” he says.

As with all forms of weed resistance, however, he emphasises it’s important not to underestimate the threat. “In other parts of the world and within Europe, herbicide resistance is more serious than it is here in the UK, so there’s scope for the issue to escalate. Make sure you’re aware of the threat, monitor levels of resistance in your own weed populations and use a range of techniques, both chemical and cultural, to combat it,” he concludes.

Change of culture as chemical control dwindles

It was in 2013 that Paul Drinkwater, manager of Abbotts Ripton Farming Company, based in Cambs, first identified herbicide resistance in his blackgrass population.

“When you see it come through the crop at flowering you know resistance has reared its ugly head, and once here, you know you’ve got it for good,” he says.

The business farms 2400ha based near Huntingdon on Hanslope series heavy boulder clay. The rotation includes winter wheat, winter barley, oilseed rape and spring beans, with potatoes and sugar beet.

“I’ve been farming these fields for 40 years and you get to know where the blackgrass is. It’s still in the same place, but we’ve always been able to control it with herbicides in the past. I thought Atlantis would see me out, but we’ve had to change our practice to get a grip on the problem,” says Paul Drinkwater.

The biggest change has been to delay drilling from mid-Sept to mid-Oct. “Being a heavy-land farmer, you have to be realist, and we go into the autumn each year and play it by ear, depending on field conditions. But we always leave the worst blackgrass fields until last.”

Sugar beet, potatoes and peas within the rotation offer another opportunity to tackle blackgrass, as they’re established in the spring, but he admits it’s limited. “The problem is the chemistry – clethodim still works for us, which is useful in sugar beet, but blackgrass control in peas is a nightmare.” For 2017, 40ha of RGT Planet spring barley will be introduced, however.

Autumn cultivations have also come shallower. “The Discordon was too aggressive, so we use a Knight press – I know they say 50mm depth should be the aim, but we find the best results all round at 75mm.” A 4m Tillso Sabre Tine with seeder has just been purchased for one-pass low-disturbance OSR establishment.

The prospect for glyphosate is a worry for Paul Drinkwater. “The biggest threat at the moment seems to be regulatory, so the first priority for the industry is to retain it as an option,” he says.

“But we use thousands of litres of glyphosate, and around every crop. So we follow the stewardship guidelines and are using water conditioners and wetters in a bid to make it more effective. Resistance is a threat, but I don’t see it becoming a problem while I’m still farming.”

He’s encouraged by the level of research that’s currently put into blackgrass management. “There’s some good work going on, and we need to know where tools such as drones and mapping are taking us. There needs to be a better level of coordination, though – there are so many different approaches now on trial. To a certain extent that’s up to growers to learn what system works best and then stick to them. But anything researchers can do to share information and offer some joined-up thinking will help,” he says.

“What’s clear, however, and very different to how things were when I started farming, is that the solutions won’t come out of a chemical can. No one’s looking too hard for a new active ingredient, so we have to get back to proper farming and rotations to learn how to stay on top of resistance.”

Research round-up

AHDB project RD-2009-3647, Sustaining winter cropping under threat from herbicide-resistant blackgrass, ran from Sept 2010 to Dec 2014. Its aim was to better quantify the impact of three non-chemical methods for control of blackgrass in combination with a robust herbicide programme. Led by Rothamsted Research, with NIAB-TAG as scientific partner, its total cost was £172,216, funded by AHDB Cereals and Oilseeds.

AHDB Project Report 556 from this project can now be downloaded at cereals.ahdb.org.uk/weeds

AHDB project 214-0006131, Managing the resistance risk to retain long-term effectiveness of glyphosate for grassweed control in UK crop rotations, runs from Oct 2015 to Sept 2020. Its aim is to provide information to develop more robust guidelines to reduce the risk of resistance. Led by ADAS, Agrii, Frontier, Hutchinsons, Agrovista and Syngenta are industry partners. Its total cost is £500,000, with £250,000 funded by AHDB Cereals and Oilseeds and the remainder funded by Monsanto, Nufarm, Albaugh and Headland (FMC) and in-kind contributions from the industry partners.

AHDB Information Sheet 03, Minimising the risk of glyphosate resistance was published in summer 2015 and can be downloaded at cereals.ahdb.org.uk/weeds

AHDB project RD-2012-3788, Preventing a wide scale increase in ALS resistant broadleaf weeds through effective management in a cereal-oilseed rape rotation, ran from Oct 2012 to Sept 2015. Its aim was to develop practical solutions to prevent an increase in ALS resistance, focusing on common poppy, chickweed and mayweed. Led by ADAS, Dow AgroSciences, DuPont and BASF were industry partners. Its total cost was £186,000, with £120,000 funded by AHDB Cereals and Oilseeds.

AHDB Information Sheet 54, Herbicide resistance in broadleaf weeds, has now been updated with the latest findings and can be downloaded at cereals.ahdb.org.uk/weeds

News and updates from the AHDB-supported Resistance Action Groups (RAGs) can be found at cereals.ahdb.org.uk/rags