In a cropping system where the soil is the priority, the drill is not the key decision. CPM travels to France to explore a system where the drill has been designed around the crops and the soils they work.

Grow a crop like this, do your own trials and you rediscover your love of farming.

By Tom Allen-Stevens

Walk into the main shed at Ferme de la Conillais, near Nantes in Brittany, France, and you’re met with a wall of Kilner jars filled with soil and seeds. Closer inspection reveals there are some 250 soil samples here, from dusty Iberian sands to fine black silts from Ukraine.

The seed collection is equally diverse – around 120 jars, with anything you could possibly wish to put through a drill, from wheat to phacelia, obscure vetches to field beans.

Tools of the trade

“These are my tools,” explains David Guy, managing director of Sky Agriculture who also owns the 170ha farm that serves as the company’s headquarters. “Some farmers have collections of old equipment. But I collect what I see as the tools of my trade – wherever I go in the world I look for unusual soils I can bring back, or seeds that might add something new to a mix.”

The collection reflects the focus on the farm: it has extensive trials of cover and catch crops, as well as companion

Christophe de Carville (left) and David Guy inspect wheat roots in a field that’s in its fifth year of no till and cover crops.

cropping, and these are all integrated into the min-disturbance, maximum ground-cover cropping policy. David Guy and his team, headed up by product manager Christophe de Carville, run regular training sessions for farmers across France, with those in the north of the country run from La Conillais.

He bought the farm in 2002. “I would have preferred to be a farmer on the rich, fertile soils of the Paris basin, but farming here presents challenges that keeps life interesting.”

Much of Brittany has a very shallow layer of sandy loam over a thick, impermeable clay. The land lies wet in winter and dries fast in summer, which means soil erosion and nutrient loss are a huge problem. Around 50,000t of farmland is estimated to be washed down the River Loire and out into the Atlantic every year, taking with it nitrates and around €15M of farmers’ inputs.

Mixed farming dominates in the area, with forage maize and arable rotations leaving soil potentially bare for long periods. So since 2000, growing cover and catch crops has been mandatory to address the erosion issues.

Twinned with this, growers are grappling with grassweeds. “My main problem here is ryegrass,” says David Guy. “When I took on the farm it was in continuous wheat, and full of ryegrass, much of which is now herbicide resistant. So we stopped ploughing and started trying to understand how the soil is functioning.”

With farmers forced to turn to cover crops, many were beginning to work this to their advantage, and David Guy joined the growing number experimenting with new crops. “We were building organic matter and finding new opportunities, such as buckwheat, that grows well in the area – it needs just 100 days from drilling to harvest and the flour is popular locally for galettes, a type of crêpe.”

But the farm’s rotation and minimum cultivation policy was failing to address the ryegrass problem on its own. The answer for David Guy was to move to direct drilling. “The best solution to control ryegrass is to keep the seeds near the surface and to disturb the soil as little as possible,” he says.

“But we have a problem in Western Europe with no till – it works well in summer and early autumn, but not later in the year or in the spring. You need to move the soil to mineralise the nitrogen and stimulate the seed to grow. If you shift to a cropping regime where you drill later in the year and in early spring, you need a system that still brings the best from your crops, while keeping a lid on grassweeds.”

Perhaps the right drill would complete the picture. David Guy had been running the farm in Brittany alongside his regular job with tillage equipment manufacturer Agrisem. “Then at the end of 2011, I met with Jacques Burel of Sulky. We discussed the drills Sulky had been developing with Moore. We also discussed my farm and where we were with our tillage and cropping system, and that was really the start of Sky Agriculture.”

Drill collaboration

Since 1974, a close business friendship between Sam Moore, of Unidrill repute, and Jacques Burel, former president of Sulky, had led to a collaboration on drill technology between the two firms. With Jacques Burel now retiring from Sulky, he was keen to see that part of the business hived off and preserved as a separate entity. “The new name for the venture – Sky – apparently came from the three letters of Sulky that were marked on a file that sat in his office,” says David Guy.

The new company is wholly owned by Sulky, while the EasyDrill, MaxiDrill and DDI disc harrows are manufactured at its Chateaubourg factory near Rennes in Brittany. But the specialist Sky team is based at Ferme de la Conillais, and that’s one of its strengths, says David Guy. “We understand the job of farming. We are facing and finding solutions for the same challenges our customers deal with.”

The farm-based training sessions form an essential part of the service, along with the phone support that puts you directly in touch with a product specialist. They’ve also amassed a wealth of research-based information from, both on-farm trials and organisations such as French grower-funded institute Arvalis.

It’s a marriage of crop and soil-based knowledge with agricultural kit that’s put into practice on the farm, not just in its trials, but in the fields as well. For instance, there’s a barley crop with peas growing within it, which begs the question, why?

“I’ve read about it – you should be able to increase yields without applying extra N,” says David Guy. “We drilled 80kg/ha each of peas and barley after maize at the end of Oct – you need a drill that will sow seeds at different depths, but we’ve needed no autumn herbicide.

“The theory is that, because the barley takes up the N produced by the peas, it encourages the pea crop to work harder and fix more N. The result is that you get more from growing them together than you would if they were separate. It needs to be crops that will mature together, and harvest might be interesting. You also need facilities to separate the two crops once harvested.”

There’s also a white clover companion crop that’s been direct drilled into a standing crop of wheat. “We drilled the clover at the beginning of March, which I think was a little late – there was a bit too much crop damage and the canopy may have grown too big to allow light to the seed. But go too early and it’s too cold and wet.”

Particular success

One field, however, is a particular success – in 2011 it heaved with more than 100 plants/m² of ryegrass. “Since then, it’s been in no till with cover crops, and we haven’t drilled the true crop before the end of Oct. You can do that because the roots of the cover crop are like a spring, allowing the drill to travel. We’ve also been careful to go slow, so as not to disturb the soil.”

This year, it’s in wheat following oilseed rape. Two days after harvesting the OSR, peas and vetch were drilled. Wheat was drilled at the end of Oct with 10kgN/ha and 25kg/ha of P2O5, and the cover sprayed off two days later.

Perhaps the most staggering aspect is that the crop has received no herbicide apart from glyphosate nor any slug pellets. “The slugs were happy to stay on the cover crop and OSR volunteers, but didn’t touch the emerging wheat. The roots are down to 40cm and there’s barely a ryegrass plant,” notes David Guy.

“Grow a crop like this, do your own trials and you rediscover your love of farming,” he adds.

The role of the cover crop

The drill is not the key decision, it’s the soil, says Christophe de Carville, and cover crops serve three important functions for it. “They capture nitrogen for free, they capture energy from the sun for free, turning it into soil structure, and they give you free tillage through the soil biology they encourage.”

And the period when many arable fields are uncropped should be their most productive. “If you had a factory, you wouldn’t close it between Aug and Nov. So why allow a field to be bare?”

Soil N mineralisation

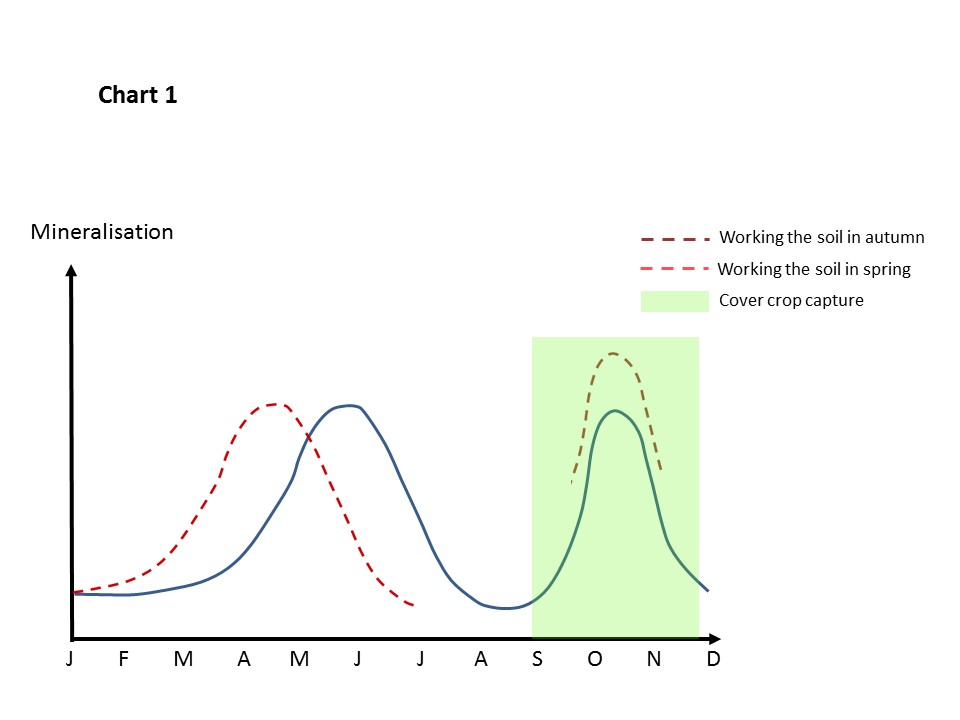

The trick with cover and catch crops is to capture the mineralised N, he says, rather than release it from the soil through cultivation (see chart below). “There are two natural peaks of N mineralisation – around May/June time and Oct/Nov. Work the soil in the autumn and you increase mineralisation. But work it in the spring and you move that peak period earlier.”

This means autumn planting date is crucial – Belgian trials have shown a crop of mustard sown at the end of Aug effectively takes up the N as it becomes available over the autumn. But plant the crop a month later and mineralised N, potentially lost through leaching, is actually increased.

The next challenge is then to release that captured N into the crop. “How much and how quickly this becomes available depends on the carbon:nitrogen ratio of your cover crop,” continues Christophe de Carville.

Leguminous crops have a lower C/N ratio, while those with more stem and straw content have a higher ratio. What’s more, the longer the crop grows before it’s sprayed off, the higher the C/N ratio climbs. “If the ratio is too low, it will deplete the organic matter and N will be lost. Too high and you will lock up N. A ratio of about 10 delivers a quick release of N into your crop.”

That comes down to the right seed mix, and every farm, every soil and every situation will be different. “That’s where you want to do your own farm trials and learn from others.”

He gives an overview as he wanders through the plots at La Conillais. “Vetch is good at capturing nitrogen, but it’s killed by the first frost, so doesn’t last. Sunflowers have a good taproot, but don’t provide much ground cover. Phacelia has a great surface root system, and isn’t in the same family as OSR, but it’s not great at capturing N.”

Mustard, on the other hand is a great scavenger – cheap, fast and efficient – but with a poor root and turns very woody by spring, making the N unavailable. “Tillage radish is great at storing N, and has a better C:N ratio, although its root won’t produce as good a seedbed as phacelia. Pulses, like beans and peas, produce their own N and complement well a crop that will draw the N up. Oats have a fantastic fibrous root that encourages soil biota. They have a high C:N ratio, so be careful they don’t lock up the N.”

Fertiliser at seeding is important for both cover crops and cash crops, he says. “N release is a long-term story and minimum soil disturbance means you don’t generally get the N stimulus the emerging seedling needs. Just 10kgN/ha can be enough, if placed correctly.”

EasyDrill essentials

- Seeder unit: there’s a tandem system, similar to sugar beet planters with a front and back reference wheel to ensure a consistent depth.

- Coulter: a single disc, angled at just 3.5° with a streamlined coulter moves as little soil as possible, but enough for a micro-tilth.

- Secondary distribution pipe: set forward, the depth matches the coulter, back, and placement is 50% of coulter depth, while furthest back puts it on the surface.

- Control wheel: in soft conditions, pressure is put on the front to firm the seedbed in front of the coulter, while weight is transferred to the back if it’s dry.

- Press wheel: the Moore, cast-iron wheel that’s bevelled to ride firmer on the side of the slot, so it’s pressed sideways together, rather than crumpled.

- Metering system: from Sulky, an automised calibration takes rates from 1-450kg/ha with separate air streams on the Fertisem option.

- Split hopper: Up to 4100-litre capacity that can take two materials up to 60:40 on the Fertisem option, or three with optional small-seed hopper.

- Pressure on drilling element: up to 250kg

- Working widths: 3m and 4m fixed; 4m and 6m fold to 3m transport width

- Drilling elements: 18, 24 and 36 at 16.6cm spacing

- Weight: 3300kg up to 7780kg

- Power required: 25-30hp/m. “180hp for a 6m drill would do in most circumstances, but it’s dangerous to have too much,” says Christophe de Carville. “The tractor may allow it, but the soil would not want you to do it.”